Poison Spyder JK BFH 07-11 DISCO SKID User Manual

Installation instruc tio ns, ’11 jk bfh disco skid install

INSTALLATION INSTRUC

TIO

NS

©2010 POISON SPYDER CUSTOMS, INC. • 951-849-5911 • WWW.POISONSPYDER.COM

‘07-’11 JK BFH DISCO SKID INSTALL

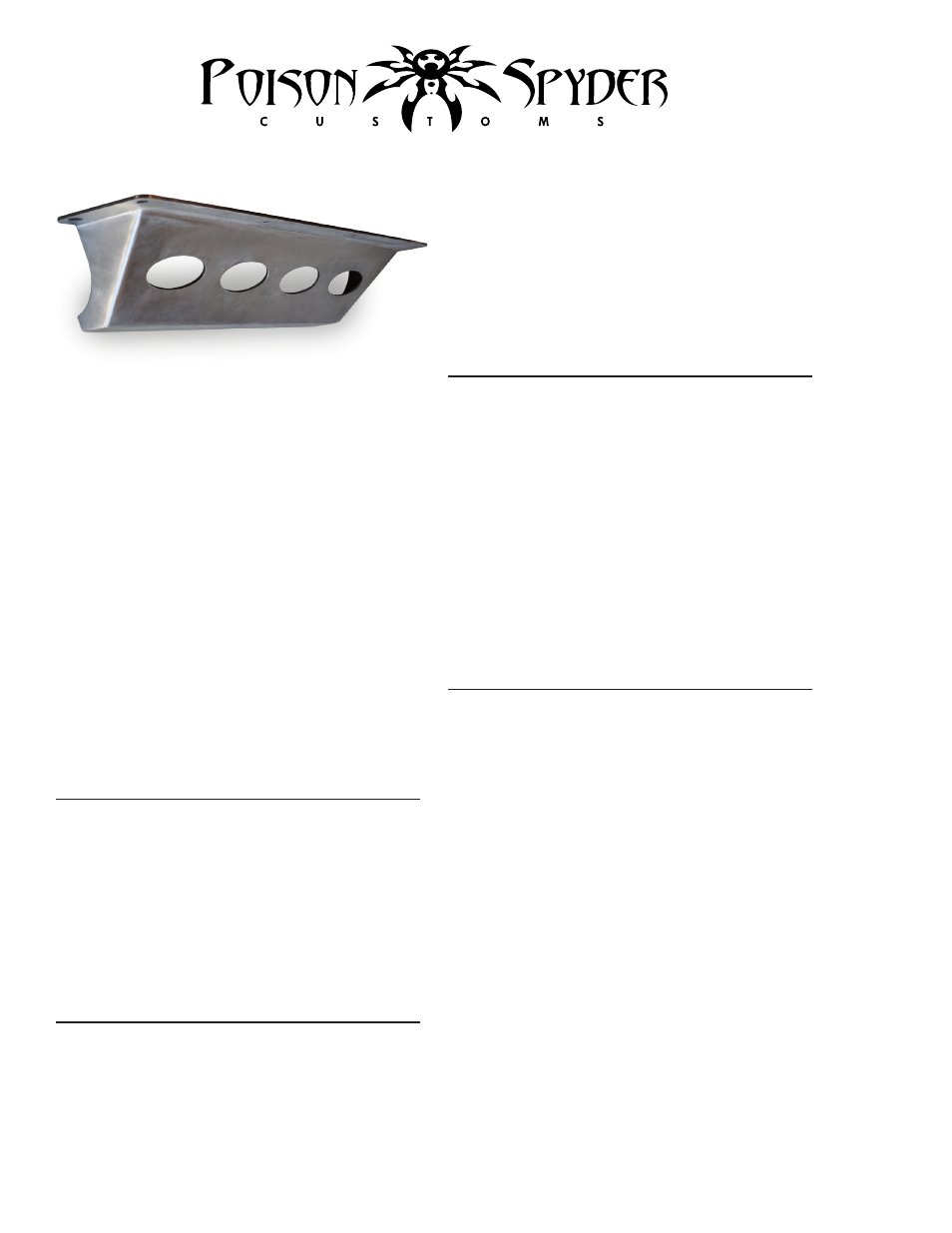

The Poison Spyder Customs JK BFH Disco Skid

is easy to install with the right tools and good

mechanical abilities. These instructions also

include the procedure for rotating your electric

swaybar disconnect motor higher. If you are

not confident in your mechanical skills, please

seek the help of a professional to perform the

installation. Please read through these entire

instructions before proceeding with installation.

IMPORTANT: The BFH Disco Skid was designed

to work with the ‘07-’11 JK Rubicon sway bar

disconnect mechanism. It is NOT designed to

work with the 2012 and newer units. Customers

may use this product on their 2012 and newer

JK Rubicon at their own discretion, but Poison

Spyder makes no warranty as to fitment or

guarantee against damage to other components

of the Jeep due to the use of this product on

2012 and newer JK Rubicons.

PARTS LIST

(1) JK BFH Disco Skid

(2) 3/8-16 X 1 Gr8 hex head cap screw

(4) 3/8 flat washer

(2) 3/8-16 nylon insert lock nut

(1) M10-1.5 X 110mm hex head cap screw

(1) M10-1.5 jam nut

(1) M10 split lock washer

TOOLS NEEDED

• 3/4 socket

• Ratchet

• 3/4 wrench

• 17mm wrench

• Torque wrench

• 3/8” drill bit and drill motor

• 17mm wrench

• Primer and paint

NOTE: The following instructions assume that a

Poison Spyder BFH Bumper has already been

installed onto the Jeep.

BEFORE YOU BEGIN

The Poison Spyder Customs JK BFH Disco Skid

comes as unpainted, bare steel. You will want

to either powder coat or paint the skid prior to

install. If painting yourself, careful preparation

will make a big difference in the quality and

longevity of your paint job, even using “rattle can”

aerosol paints. Begin by thoroughly cleaning the

skid with solvent or de-greaser, then make sure

all residue is removed. Even if you use cheap

paint, try to use a good quality primer. “Etching”

primers are best to use on bare, unpainted

metal. Allow it to properly dry before painting,

and between paint coats.

INSTALLATION PROCEDURE

1. Park the Jeep on a flat, level surface and

set the parking brake.

2. Begin with the procedure to rotate the

swaybar disconnect motor up out of the

way. Remove the bolt that passes through

the rubber motor indexer. Make sure there

is enough slack in the electrical harness to

rotate the motor (you may need to cut one of

the retainer clips).

3. Rotate the motor upward (the motor

assembly will spin on the sway bar). There

are several bolts which hold the two halves

of the motor housing together. Determine

which one most closely aligns with the bolt

hole in the rubber indexer, with the motor

rotated as high as possible. Remove this

bolt from the motor housing.

4. Insert the supplied M10-1.5 X 110mm bolt

through the rubber indexer. Thread the

supplied M10 jam nut onto the bolt, followed

by the M10 lockwasher. Then thread the