Installation instruc tio ns – Poison Spyder JK ROCKER KNOCKERS User Manual

Page 4

INSTALLATION INSTRUC

TIO

NS

Poison Spyder Customs • JK ROCKER KNOCKERS INSTALLATION

Page 4

©2009 POISON SPYDER CUSTOMS, INC. • 951-849-5911 • WWW.POISONSPYDER.COM

can catch and distort the metal.

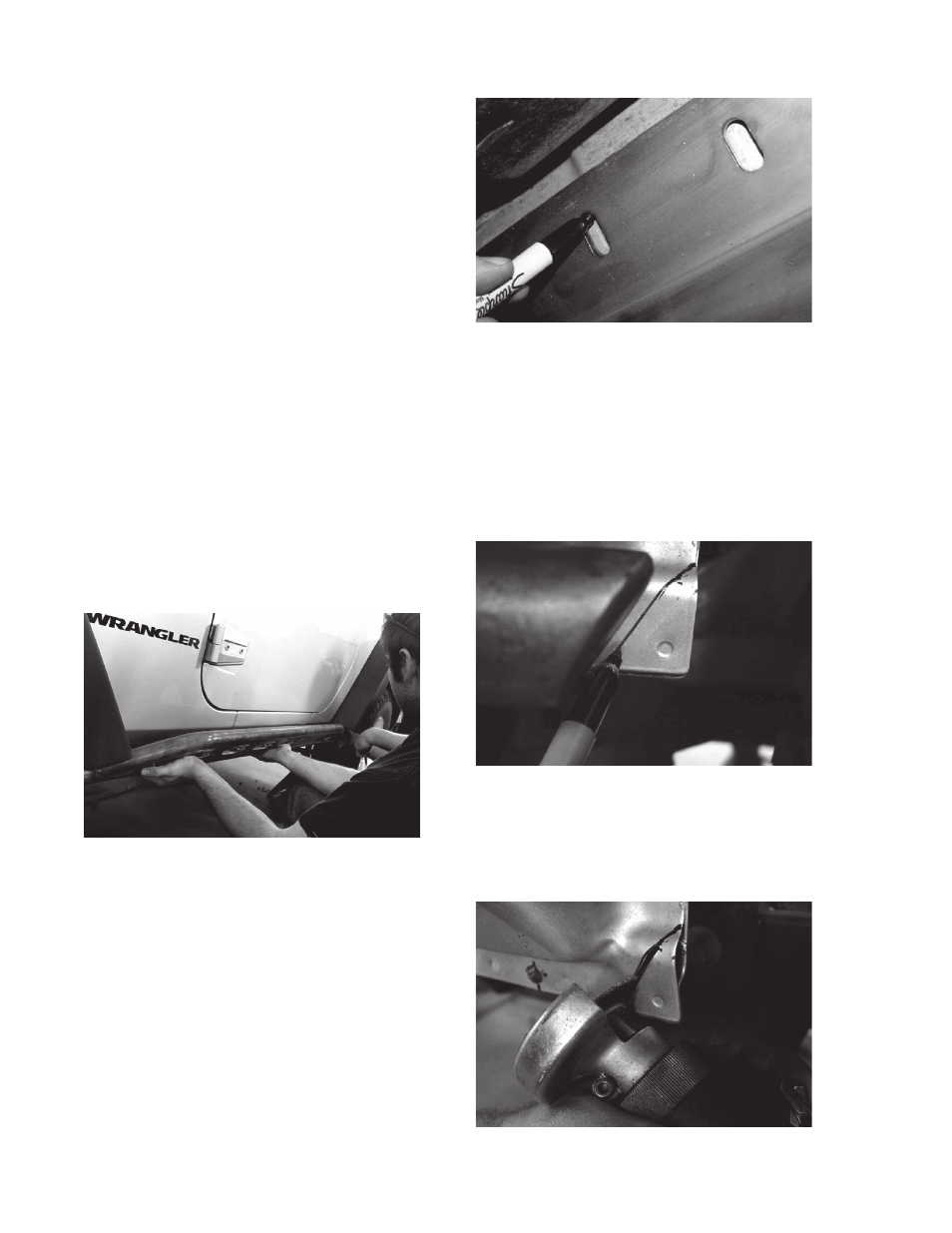

5. (Optional) Use the die grinder to elongate

the holes in the pinch weld about 1/16”

toward the front and back. The holes should

now have the appearance of an oval. This

step will make it easier to install and remove

the Rocker Knockers.

6. If you are installing Rocker Knockers with

Sliders, remove the dimpled panel at this

time and set aside. For this you will need

your 7/16” socket, 3” extension and 1/4” drive

ratchet, as well as a 5/32” hex key. As an

optional step to achieve a more unique look,

you may paint or powder-coat these dimpled

panels, in order to provide some additional

color to your Jeep.

7. Have a helper assist you for the following

steps. Hold the Rocker Knocker up to the

rocker area of the Jeep, and carefully align

the six (6) mounting studs of the Rocker

Knocker with the six holes in the pinch weld

seam. Slide the Rocker Knocker into place,

with the studs protruding through the holes in

the pinch weld flange.

FIGURE 10

8. With your helper applying pressure to the

Rocker Knocker against the side of the Jeep,

use a fine-tip felt marker to trace the six

(6) elongated holes in the Rocker Knocker

mounting flange under the Jeep.

FIGURE 11

9. (Optional) For additional tire clearance at

both ends of the Rocker Knocker, you may

trim a small corner of the Jeep’s body tub at

either end of the Rocker Knocker. With the

Rocker Knocker installed (it is temporarily

installed at this time, it will be removed again

before final installation), use a fine-tip felt

marker to trace an angled cut mark on the

corner of the body tub as shown.

FIGURE 12

Align the cut mark with the angle of the end

of the Rocker Knocker tube. After the Rocker

Knocker is removed (in later steps), trim the

corner with a pneumatic cut-off wheel, body

saw or reciprocating saw.

FIGURE 13