Driveline clamp cone yoke operating instructions, Blade servicing, Maintenance – Alamo FC-0016 User Manual

Page 148

MAINTENANCE

A96B 03/06

Maintenance Section 5-6

© 2006 Alamo Group Inc.

MAINTENANCE

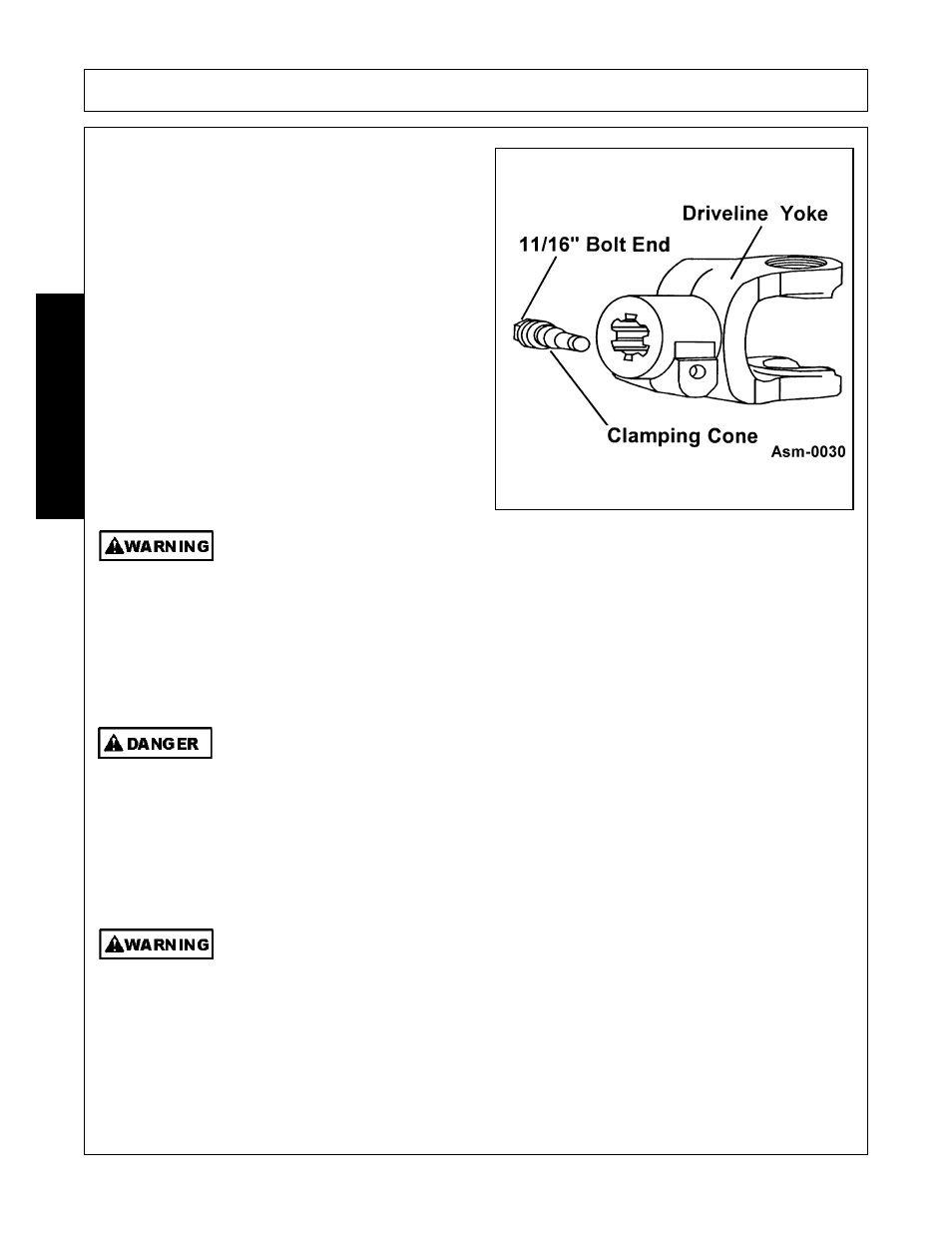

DRIVELINE CLAMP CONE YOKE

OPERATING INSTRUCTIONS

Loosen the yoke clamp cone with a 11/16” (17mm)

wrench and remove the cone from yoke. Slide yoke onto

the shaft and align hole for clamping cone with annular

groove of gearbox shaft. Reinstall cone and tighten

(75lb-ft. torque). Push and pull the driveline to ensure it

is securely attached to the shaft. Regularly check the

driveline yoke to ensure a tight connection. To remove

the yoke, remove the connecting cone and pull yoke off

the shaft. If the cone cannot be easily removed by hand,

drive it out from the other side using a hammer and

punch.

NOTE: The clamping cone is serviced only as a

complete assembly. Do not attempt to disassemble the

clamping cone.

When attaching PTO yoke to tractor PTO shaft, it is important that spring-activated locking

collar slides freely and locking balls are seated in groove on PTO shaft. A loose shaft could

slip off and result in personal injury or damage to cutter.

BLADE SERVICING

Inspect blades before each use to determine that they are properly installed and in good condition. Replace

any blade that is bent, excessively nicked, worn, or has any other damage. Small nicks can be ground out

when sharpening.

Replace bent or broken blade with new blades. NEVER ATTEMPT TO STRAIGHTEN OR

WELD ON BLADES SINCE THIS WILL LIKELY CRACK OR OTHERWISE DAMAGE THE

BLADE WITH SUBSEQUENT FAILURE AND POSSIBLE SERIOUS INJURY FROM

THROWN BLADES.

(SGM-10)

IMPORTANT! When sharpening blades, grind each blade the same amount to maintain balance. The

difference in blade weights should not exceed 1 ounce. Unbalanced blades will cause excessive vibration

which can damage gear box bearings. Vibration may also cause structural cracks in cutter housing.

Use only original equipment blades on this cutter. They are made of special heat-treated

alloy steel. Substitute blades may not meet specifications and may fail in a hazardous

manner that could cause injury.