Check hydraulic oil level and refill hydraulic oil, Check hydraulic unit, Check water cooler and maintain it – Karcher ICC 2 D ECO 2SB STAGE IIIa User Manual

Page 36: Clean and replace fuel filter, Deaerating the fuel system

-

14

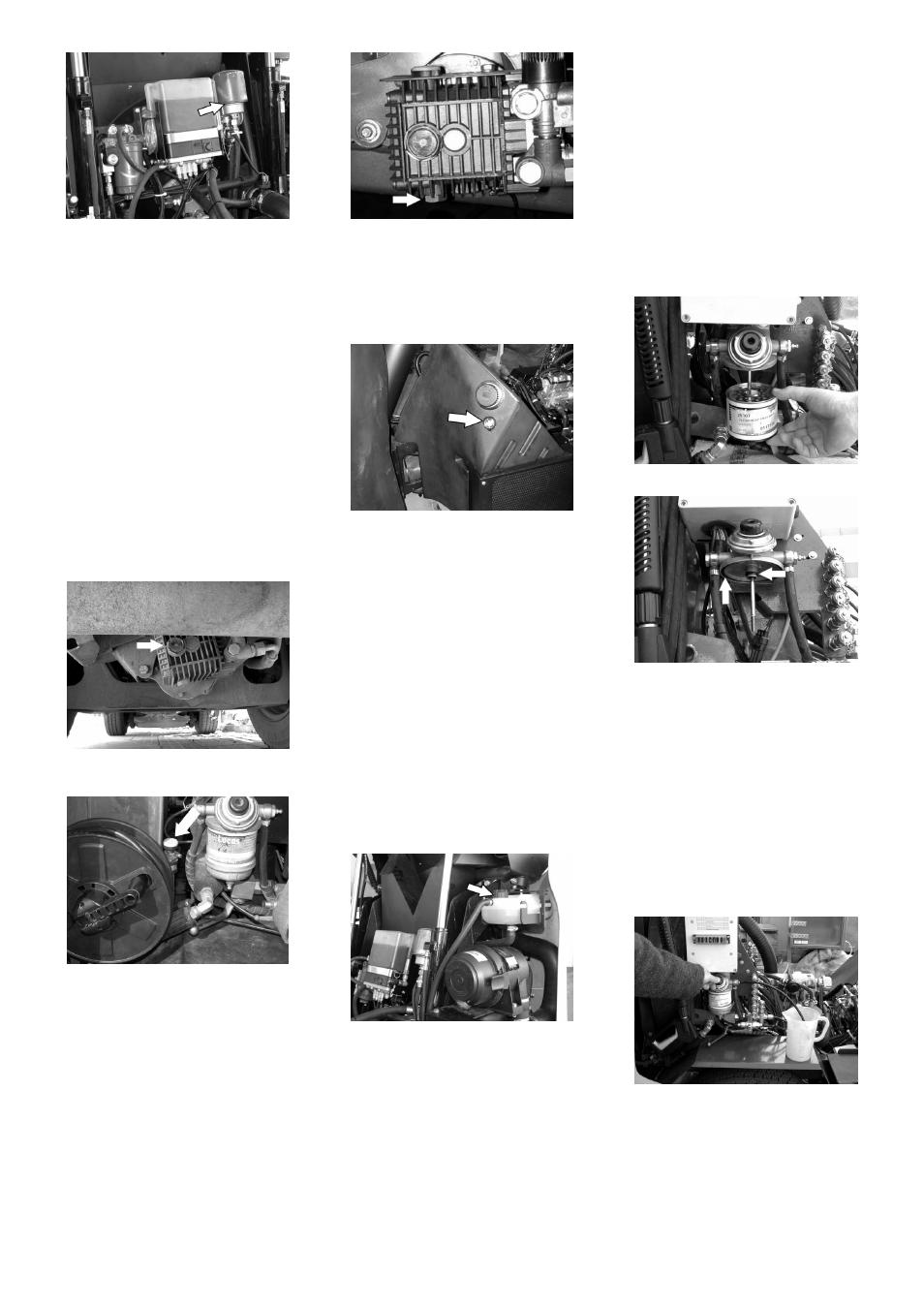

Unscrew the oil filter.

Clean the intake and sealing areas.

Coat the washer of the new oil filter with

oil before fitting it.

Fit in the new oil filter and tighten it by

hand.

Screw in the oil drain screw along with

the new washer.

Note

Tighten the oil drain screw using a torque

wrench to 25 Nm.

Fill in motor oil.

Oil grade: see Technical Data

Close oil filler opening.

Let the motor run for approx. 10 sec-

onds.

Check engine oil level.

The oil level must be within the viewing

glass.

Refill oil:

Clean the filling area.

Loosen the screw cap of the oil filling

opening.

Refill oil.

Close oil filler opening.

Check oil level.

Oil change:

Ready a catch bin for appr. 1 litre oil.

Unscrew oil drain plug.

Oil grade: see Technical Data

The oil level must be within the viewing

glass.

Clean the filling area.

Loosen the screw cap of the oil filling

opening.

Refill hydraulic oil.

Oil grade: see Technical Data

Check all hydraulic hoses and connec-

tions and ensure that they are leak-

proof.

Only Kärcher Customer Service is author-

ised to carry out maintenance tasks on the

hydraulic unit.

ƽ

Danger

Danger of scalding by boiling water! Let the

cooler cool down for at least 20 minutes.

Fill in cold water in the cooling water

compensation tank.

If the motor is cold:

–

Cooling water level must be above the

lower marking.

If the motor is warm:

–

Cooling water level must be below the

upper marking.

–

The percentage of anti-frost agent in

the cooling water should not be more

than 50%.

ƽ

Danger

Risk of explosion!

–

Do not carry out maintenance tasks in

closed rooms.

–

Smoking and naked flames are strictly

prohibited.

Switch off engine.

Raise waste container.

Keep a suitable catch bin ready.

Loosen the fuel filter casing.

Empty the fuel filter casing.

Remove the fuel filter casing.

Clean or replace fuel filter.

Replace washers.

Fit the fuel filter again.

Check fuel tubes and clamps for dam-

ages and make sure they are leak-

proof.

Deaerate the fuel system

Raise waste container.

Insert the hose on the deaeration

screw.

Turn the deaeration screw by one rota-

tion.

Keep a suitable catch bin ready.

Pump until fuel free of air bubbles is re-

leased.

Close the deaeration screw.

Check oil level in the water pump; refill

and change oil

Check hydraulic oil level and refill hy-

draulic oil

Check hydraulic unit

Check water cooler and maintain it

Clean and replace fuel filter

Deaerating the fuel system

36

EN