NORD Drivesystems BU0220 User Manual

Page 90

PROFIBUS DP

– Supplementary manualfor NORD Frequency Inverter SK 2xxE

90

Subject to technical amendments

BU 0220 GB-0912

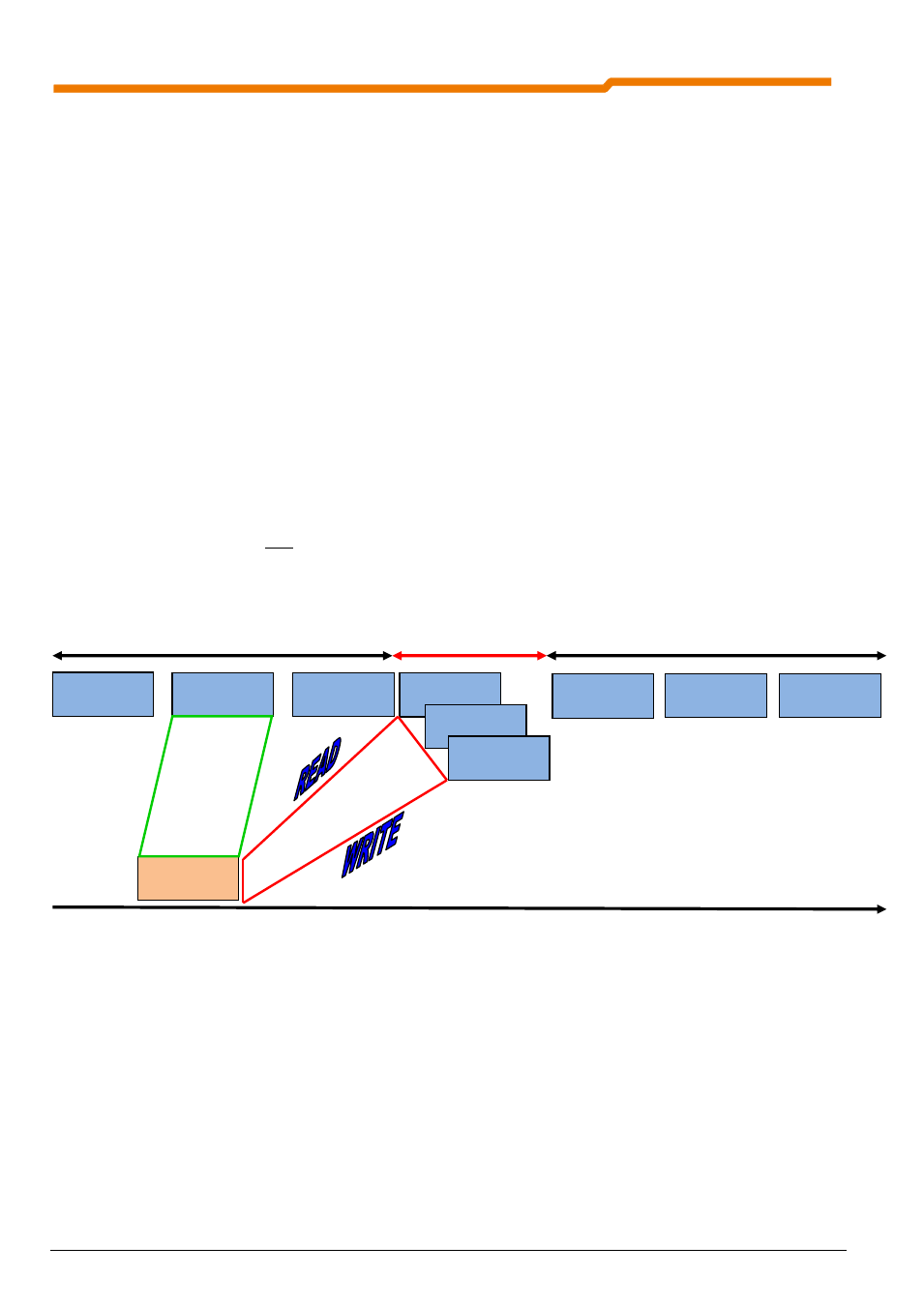

8.3.4.4 Cyclic and acyclic data traffic

The PROFIBUS technology units enable field bus access to all parameters and functions of the frequency

inverter.

Cyclic reference data traffic (process data) enables rapid control of bus participants. Via the standardised

process data channel (parameter process data object (PPO)) setpoints (setpoint frequency, position setpoints,

current limits etc.) are transferred from the automation device to the frequency inverter. Via the same process

data channel, actual values (actual frequency, actual position, current values, error numbers etc.) and status

information is read back from the frequency inverter to the automation device. Selection of the PPO type is

carried out via the hardware manager (Section 4.2.2 ). The SK xU4-PBR bus module automatically detects the

PPO type which is used and sets it for communication to the frequency inverter.

However, some applications require interventions by the user (adaptation of parameters). These interventions

can be carried out

cyclically via the parameter code value channel (only PPO types 1 or 2 and only for frequency inverter

parameters) within the process data, or also

acyclically via special READ / WRITE commands according to the PROFIBUS DP-V1 specification.

Parameter adaptations of the Profibus module SK xU4-PBR (parameter (P150) ... (P154) can only be carried

out via acyclic data communication.

The acyclic data traffic is carried out parallel to the cyclic reference data traffic of the process information

during operation and can only be used for parameterisation. For the acyclic data traffic, a 4 byte data block,

which corresponds to the PKW component of PPO types 1 and 2 is transferred via the PROFIBUS DP.

The acyclic exchange of data sets can extend over several bus cycles or their "gaps".

With SIMATIC STEP 7 applications, two ready-made system modules are available for the handling of acyclic

data traffic.

parameter

PKW

Reading

and writing of

the

DP master

t

DP Slave 1

DP Slave 2

DP Slave 3

DP Slave 1

DP Slave 2

DP Slave 3

DP Slave 2

DP Slave 1

DP Slave 2

Cyclic PZD

Acyclic PKW

Cyclic PZD

Reading and

writing of the

process data

PZD

PROFIBUS DP

DP-V1