3 cable layout and shielding (emc measures) – NORD Drivesystems BU0220 User Manual

Page 77

BU 0220 GB-0912

Subject to technical amendments

77

NOTE

The lower the shielding resistance of the PROFIBUS DP cable, the better the EMC quality.

The electromagnetic compatibility (EMC) describes the normally required state, that

technical devices do not interfere with each other due to electrical or electromagnetic

effects.

8.1.3

Cable layout and shielding (EMC measures)

If EMC measures are not in place, high-frequency interference which is mainly caused by switching processes

or lightning often causes electronic components in the bus subscribers to be faulty and error-free operation can

no longer be ensured.

Appropriate shielding of the bus cable reduces electrical interference which can arise in an industrial

environment.

The best shielding characteristics are achieved with the following measures:

Do not make cable connections shorter than 1m between bus participants

Avoid long connections between bus subscribers

Shield the bus cable on both ends with large-area connection to the plug housing

Avoid spur lines (above 1.5MBaud spur lines are no longer permissible)

Avoid extensions to bus cables via plug connectors

Bus lines should be laid with a minimum spacing of 20cm to other lines which carry a voltage higher than 60V.

This applies to lines laid inside and outside of control cabinets.

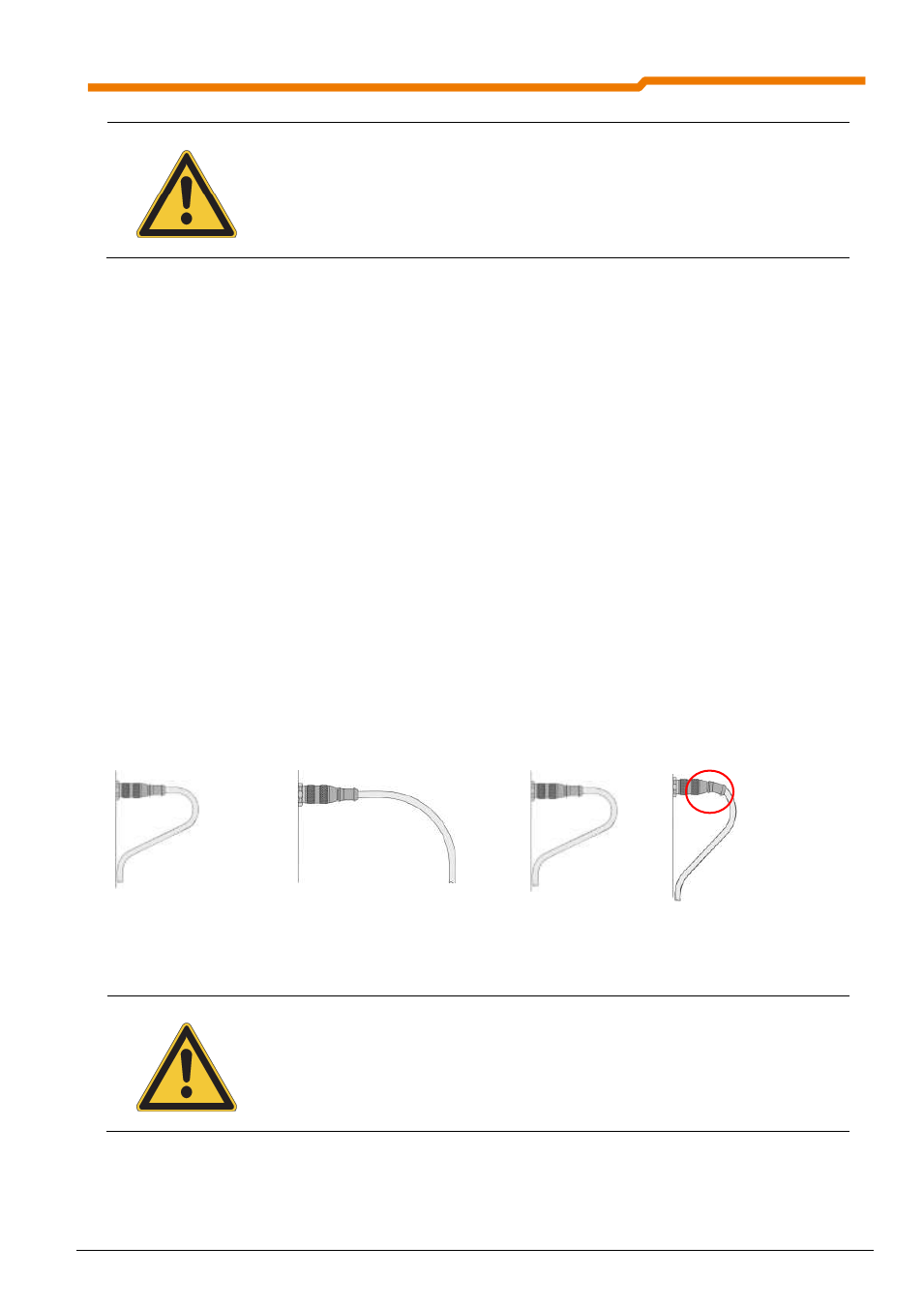

Special attention should be paid to bending radii:

Fixed cable

Freely laid cable

Bending radius of cable

Minimum radius

5 x cable diameter

Minimum radius

10 x cable diameter

Correct

Incorrect

NOTE

If earthing potential values are different, transient current may flow through shielding which

is connected on both sides. This may be a danger to electronic components. Differences in

potential must be reduced by means of adequate potential equalisation.