4 terminology (selection) – NORD Drivesystems BU0220 User Manual

Page 88

PROFIBUS DP

– Supplementary manualfor NORD Frequency Inverter SK 2xxE

88

Subject to technical amendments

BU 0220 GB-0912

8.3.3.2 PROFIBUS DP-V1

Amongst other things, DP-V1 contains additions for process automation and a series of event-related

functions, in particular acyclic data traffic.

Acyclic exchange of process data for parameterisation, operation, observation and alarm processing of

intelligent field devices in parallel with the cyclic reference data traffic.

Diagnostic functions, status alarm, update alarm and alarm processing specific to the manufacturer.

Exchange of data during the DP slave initialisation phase

DP-Master Class 2 - Communication (Section 8.3.2 "Device types" - E.g.: touch panel)

DP master - master communication (between masters)

Acyclic data traffic, which is made possible by DP-V1 allows the parameterisation and calibration of the

connected field devices simultaneously to the cyclic exchange of data.For this, a four-word I/O module is used,

which corresponds to the Parameter Label Value (PKW) section of PPO types 1 and 2 (see also Section 7.2

"PROFIBUS DP PPO types").

Up to 4 frequency inverters connected via a BUS technology unit can be managed independently from the

master via this channel. A DP master Class 1 (DPM1, e.g. PLC or PC) can simultaneously access up to three

DP master Class 2 (DPM2, engineering, planning or control devices) in parallel to a technology unit.

Requirements by more complex applications and devices (field devices for process automation, intelligent

operating and observations devices, frequency inverters), which often require parameterisation during

operation, can therefore be easily implemented.

With the use of this performance class, the parameter values are only rarely changed in comparison to the

cyclic measurement values.

8.3.4

Terminology (selection)

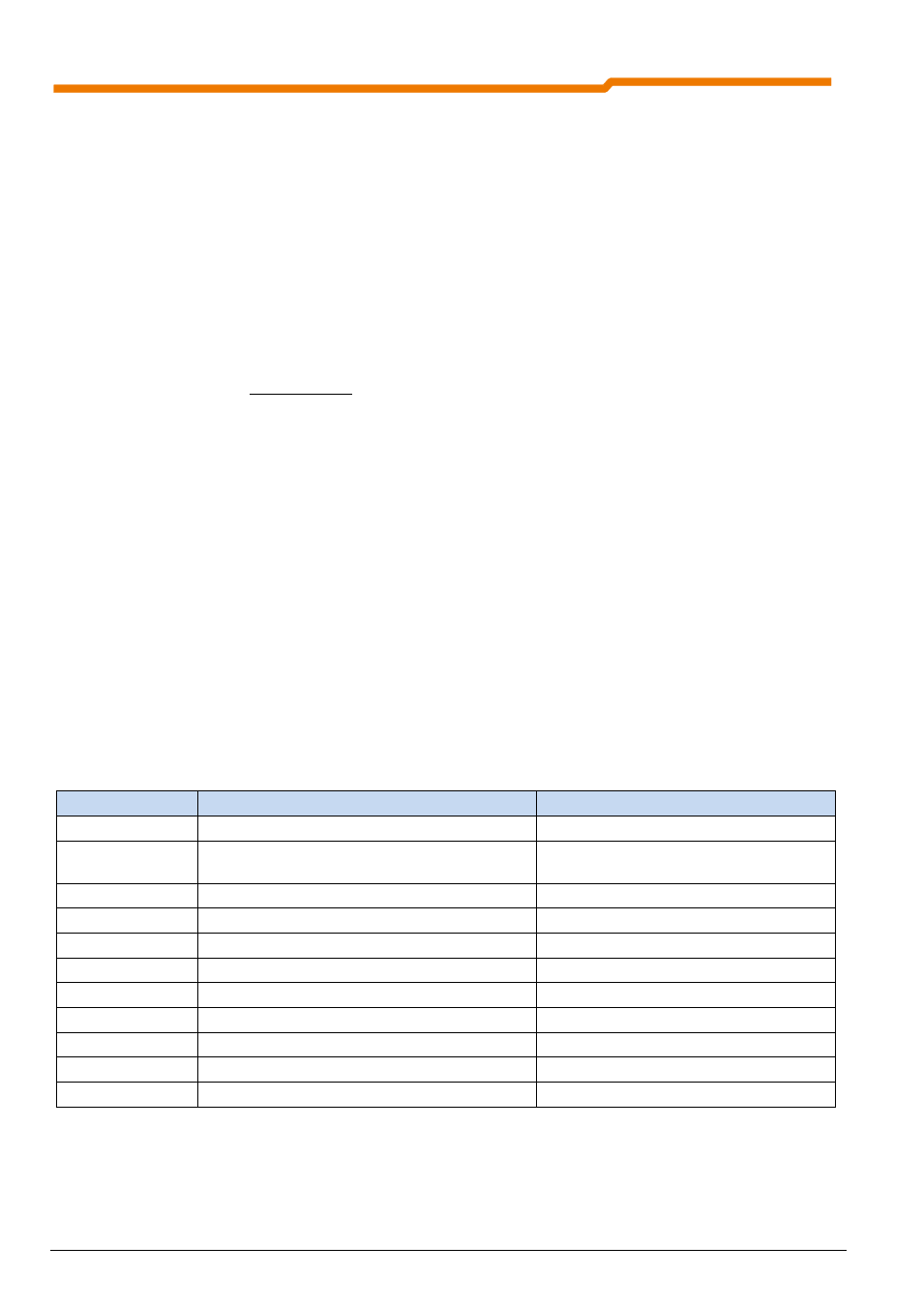

8.3.4.1 Bus parameters

Bus parameters are settings which define the time-related behaviour on the physical PROFIBUS DP. The

following standardised parameters are set in the DP master by means of the configuration tool. In more recent

configuration tools, this is usually carried out automatically:

Name

Meaning

Value range

TS

Master address

0 to 126

Baud rate

Transfer rate

10 options

(Section 8.1.2 "Cable material")

T

SL

Slot Time

5

2

2

16

-1 (bit times)

min T

SDR

Smallest Station Delay Responder

2

0

to 2

16

-1 (bit times)

max T

SDR

Largest Station Delay Responder

2

0

to 2

16

-1 (bit times)

T

QUI

Quiet Time

0

to 2

8

-1 (bit times) (standard value =0)

T

SET

Setup Time

2

0

to 2

8

-1 (bit times)

T

TR

Target Rotation Time

2

0

to 2

24

-1 (bit times)

G

GAP Update factor (token cycles)

1 to 100 (Standard value = 10)

HSA

Highest Station Address

2 to 126 (Standard value = 126)

Max retry limit

Maximum retries (number of repeat telegrams)

0 to 8