2 electrical connection, 1 cable gland – NORD Drivesystems BU0220 User Manual

Page 19

BU 0220 GB-0912

Subject to technical amendments

19

2.2 Electrical connection

WARNING

THE DEVICES MUST BE EARTHED.

Safe operation of the devices requires that is installed and commissioned by qualified personnel

in compliance with the instructions provided in this Manual.

In particular, the general and regional installation and safety regulations for work on high voltage

systems (e.g. VDE) must be complied with as must the regulations concerning correct use of tools

and the use of personal protection equipment.

Dangerous voltages can be present at the motor connection terminals of the frequency inverter

even when the inverter is switched off. Always use insulated screwdrivers on these terminal fields.

Ensure that the input voltage source is not live before setting up or changing connections to the

unit.

Make sure that the inverter and motor are specified for the correct supply voltage.

2.2.1

Cable gland

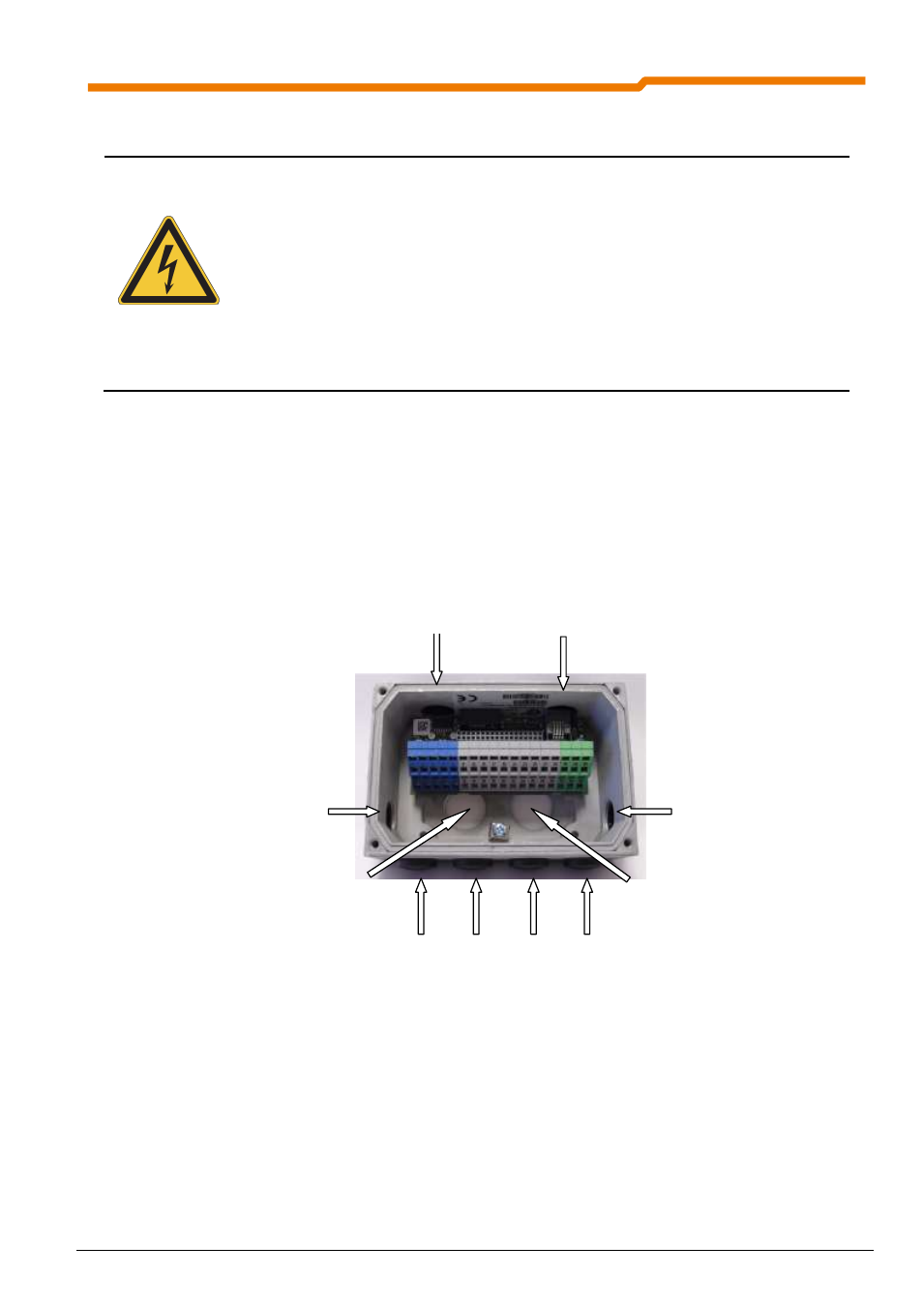

Both the SK 200E connection unit and the bus module provide extensive facilities for the connection of all the

required cables. The cables may enter the housing via cable glands and be connected to the terminal bar.

However, appropriate round plug connections (e.g.: M12 round plug connectors in M16 cable glands) may be

fitted in order to provide a plug-in solution.

Outgoing cable, fixed

connection e.g. for system

bus or 24V supply

Incoming cable, fixed

connection e.g. for system

bus or 24V supply

Cable gland for system bus cable pair

and 24V supply for direct attachment

to SK 200E

No function,

do not use

Diagnostic access

RJ 12 socket

Cable gland for system bus cable pair

and 24V supply for direct attachment

to SK 200E

M16 cable gland or installation of M12 round plug connection for:

incoming and outgoing PROFIBUS DP cable

24V and 24V (for DO) supply

System bus

I/O peripherals: sensors and actuators