2 control connections – NORD Drivesystems BU0220 User Manual

Page 20

PROFIBUS DP

– Supplementary manualfor NORD Frequency Inverter SK 2xxE

20

Subject to technical amendments

BU 0220 GB-0912

2.2.2

Control connections

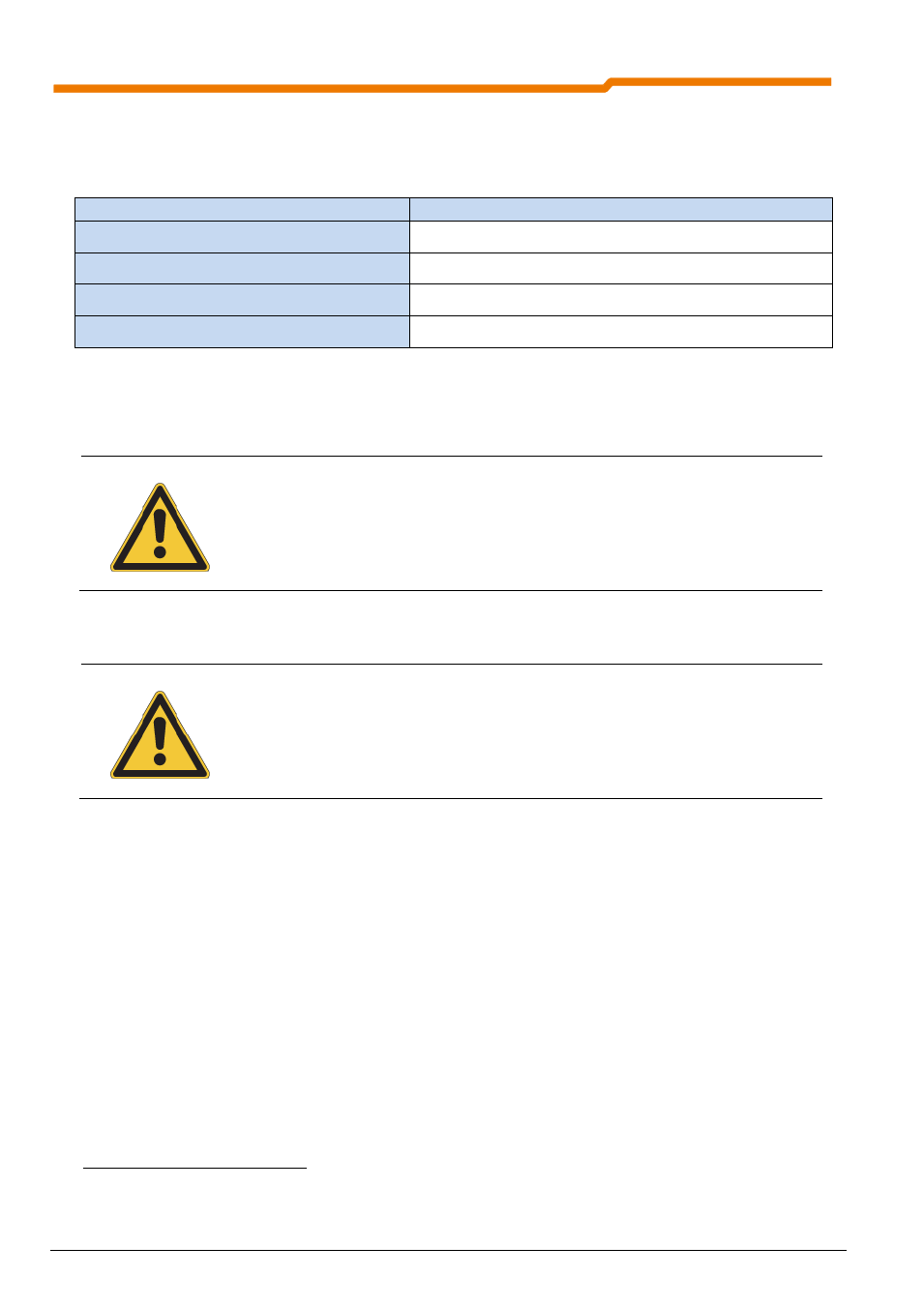

The PROFIBUS DP modules must be provided with a 24V DC (±20%, 100mA) control voltage. Wire end

sleeves must be used for flexible cables.

Name

Data

Rigid cable cross-section

0.14 … 2.5mm²

Flexible cable cross-section

0.14 … 1.5mm²

AWG standard

AWG 26-14

Tightening torque (for screw terminals)

0.5 … 0.6Nm

Within the terminal box (unshielded cable section) the data cables (e.g. PROFIBUS DP, system bus) must be

installed as short as possible and of equal length. Associated data cables (e.g.: Sys+ and Sys-) must be

twisted.

NOTE

The PROFIBUS DP is already installed in the customer unit with voltage isolation from the

other signal connections.

In case of EMC problems, voltage separation of the field bus supply, the digital inputs and

system bus interface and for the external technology unit also for the two additional digital

outputs should be provided.

NOTE

The cable shielding must be connected to the functional earthing

1

(usually the

electrically conducting mounting plate) in order to prevent EMC interference in the

device.

In order to achieve this, for PROFIBUS DP connections it is mandatory that the metallic

metric EMC screws are used for the connection of the PROFIBUS DP shielding lead to the

frequency inverter or the housing of the technology unit. This ensures a wide area

connection of the functional earthing.

1

In systems, electrical equipment is usually connected to a functional earth. This serves as a means to dissipate leakage

and interference currents in order to ensure EMC characteristics and must therefore be implemented according to high

frequency technology aspects.