1 process data (pzd) – NORD Drivesystems BU0220 User Manual

Page 60

PROFIBUS DP

– Supplementary manualfor NORD Frequency Inverter SK 2xxE

60

Subject to technical amendments

BU 0220 GB-0912

7.2.1

Process data (PZD)

In the process data area (PZD), control words and setpoints are transferred from the master to the slave

(frequency inverter) and in return, status words and actual values are sent from the slave to the master. The

structure of the PZD area is always the same in terms of the sequence of its elements (words), however,

dependent upon direction of data Master

inverter / inverter

Master, it is described differently.

The process data area of the reference data has the following structure:

-

STW:

Control Word; length 16 bit, order telegram

contains control bits (e.g. enable, rapid stop, error acknowledgement)

-

ZSW:

Status Word; length 16 bit, response telegram

contains status bits (e.g. FI running, fault)

-

SW1..3:

Setpoints; maximum 3 possible, 16 or 32Bit, order telegram

e.g. frequency setpoint value, position setpoint value, torque setpoint value

-

IW1..3:

Actual values; maximum 3 possible, 16 or 32Bit, response telegram

e.g. actual frequency value, actual position value, actual torque value

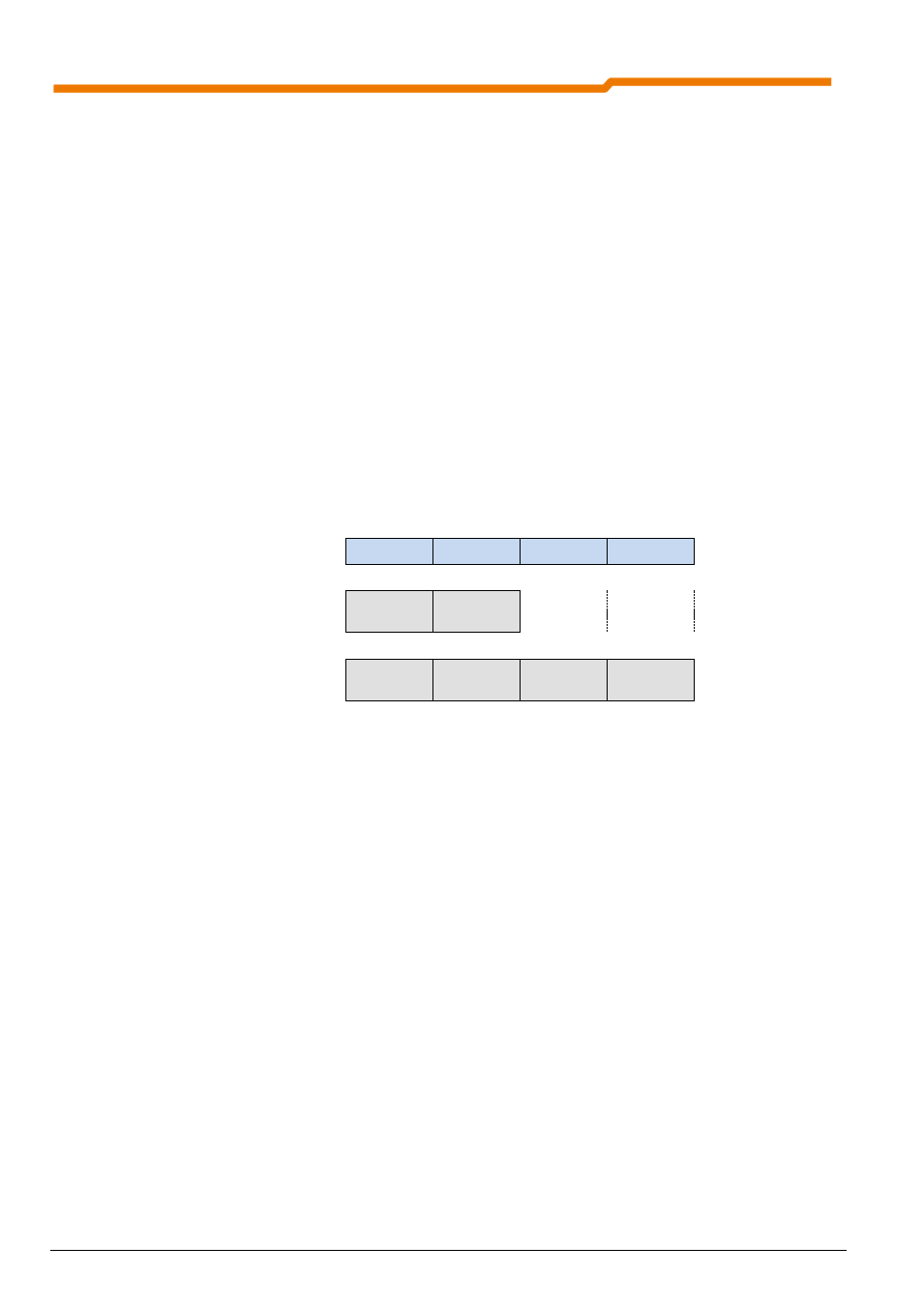

1.(/5.) word 2.(/6.) word 3.(/7.) word 4.(/8.) word

PZD area with

1x16-Bit setpoint

STW

ZSW

SW1

IW1

PP0 Type

(1,)3

PZD area with up to 3

16-Bit setpoints

STW

ZSW

SW1

IW1

SW2

IW2

SW3

IW3

PP0 Type

(2,)4

Note: 32-Bit setpoints consist of High and Low words (16-Bit each).