Badger Meter SRD/SRI Valve Positioners User Manual

Page 67

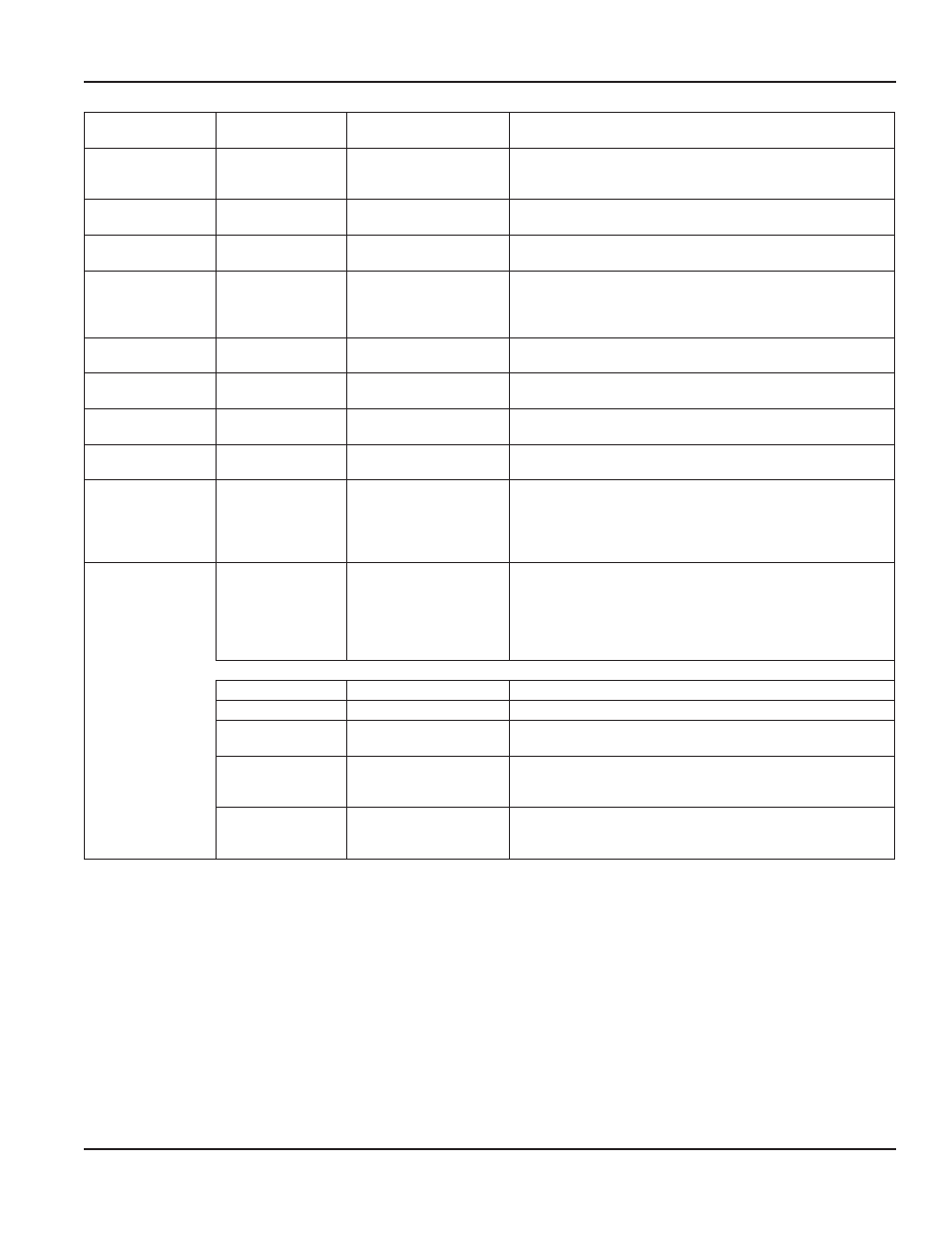

Message

Status

Description /

Explanation

Recommended Action

Cycle Count Limit

Maintenance

Required

Cycle Count has

exceeded limit

configured .

Check valve performance and conduct maintenance if

necessary .

Input Loop Trim

Maintenance

Required

Input signal requires

calibration .

Perform Analog Setpoint Calibration procedure .

Feedback Trim

Maintenance

Required

Feedback unit requires

calibration .

Perform Angle Calibration procedure .

No Autostart done

—

No Autostart was done

or Autostart was run

and did not complete

successfully .

Ensure proper mounting of positioner and adequate supply

pressure . Refer to online Help for other potential causes . Rerun

Autostart Calibration procedure .

Position High Alarm Good

Position above High

Alarm Setpoint .

Monitor situation or correct cause .

Position Low Alarm

Good

Position below Low

Alarm Setpoint .

Monitor situation or correct cause .

Position High High

Alarm

Good

Position above High High

Alarm Setpoint .

Monitor situation or correct cause .

Position Low Low

Alarm

Good

Position below Low Low

Alarm Setpoint .

Monitor situation or correct cause .

Control Diff OOL

Maintenance

Required

Difference between

setpoint requested and

current position exceeds

allowed limit for a user

specified time .

Check to ensure that there is adequate supply pressure . Verify

tuning parameters . Check mechanics of actuator and valve .

Refer to troubleshooting section of SRD991 users manual .

Partial Stroke

Testing

—

The Partial Stroke

Testings allows to

evaluate if an Emergency

Shutdown Device (ESD)

will operate in case of a

safety shutdown .

The Partial Stroke Test can be found under the Configuration/

Partial Stroke . This is where the Test can be configured and

activated . The Testing Status shows the evaluation of the test .

Testing Status

Good

Not Done

A Partial Stroke Test has not been executed yet .

Good

Running

Test has been started and is in progress .

Local Operation

Restricted

Test is restricted . Either the valve is in control or the valve is not

fully open (100%) .

Good

OK

Test performed OK . The ESD capabilities have been tested and

showed that the valve is not stuck . The valve would move if a

safety system would close the valve .

Failure

Error

Test showed Error . The ESD capabilities cannot be guaranteed .

The valve is stuck and cannot move . The valve needs to be

inspected immediately!

Diagnostics

Page 67

August 2014

POS-UM-00011-EN-02