Troubleshooting – SHIMPO CAG-2000 1 Channel User Manual

Page 46

44

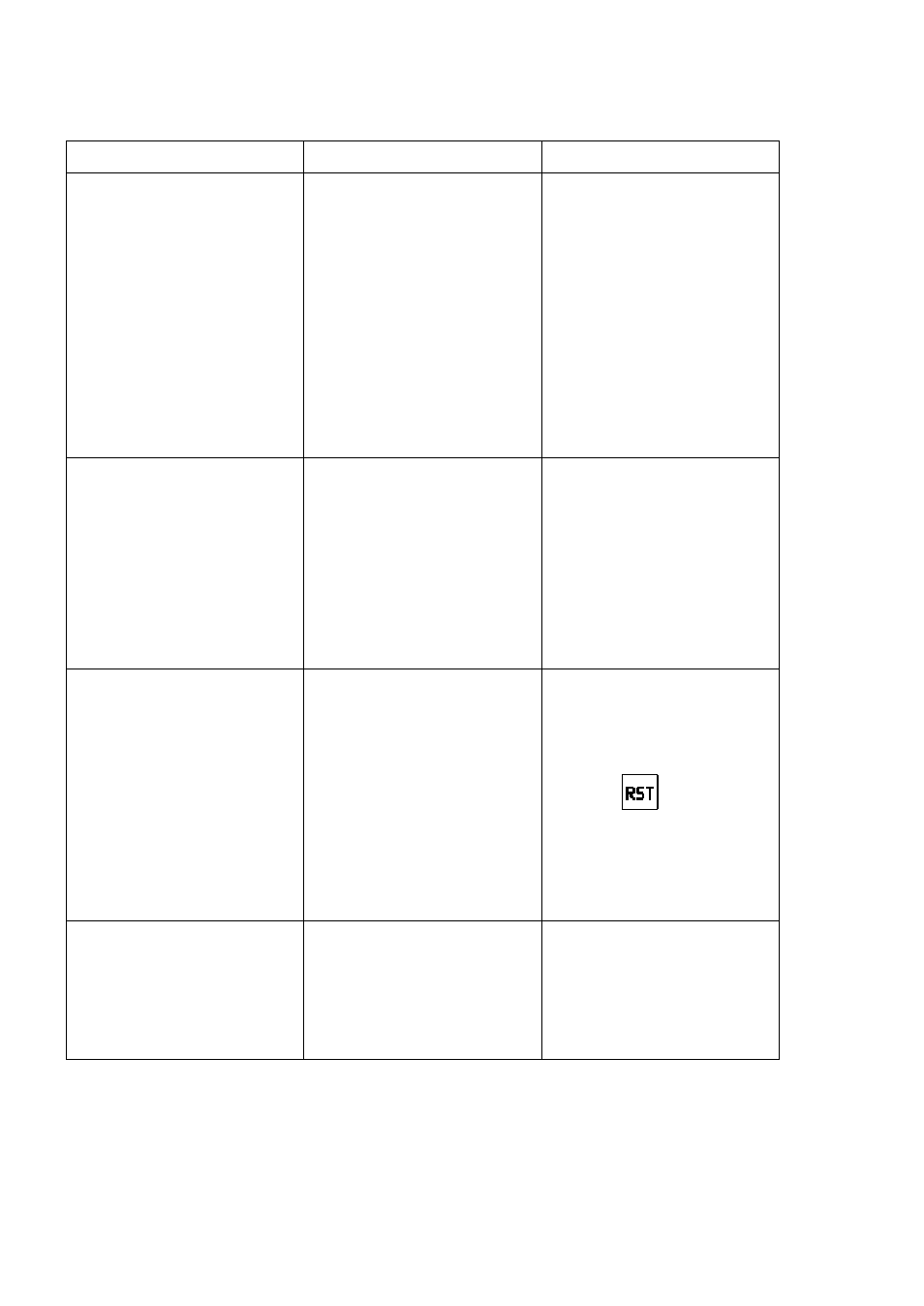

15. Troubleshooting

Phenomenon

Cause

Remedy

Air supply pressure is not

stable.

Set regulator source

pressure at 300 kPa or

more.

Regulator is

malfunctioning.

Overhaul or change it.

Measuring nozzle is worn. Change it.

Repeatability is not stable.

Piping and joints are

leaking.

Entry of moisture or oil

causes trouble to

instrument.

Check for leakage, and

retighten.

Clean instrument.

Air supply pressure is too

low or high.

Set regulator at 196 kPa.

Piping and joints are

leaking.

Check for leakage, and

retighten.

Gap of measuring nozzle

is too small.

Adjust to proper gap.

Zero adjustment knob is

ineffective.

Gap of measuring nozzle

is too large.

Adjust to proper gap.

Specified power is not

supplied.

Supply power of 85 to 264

VAC.

Zero position of air circuit

is improperly adjusted.

Calibrate instrument with

masters.

Instrument is in hold

measured value mode.

Bargraph display is

illuminated green or red

(dark).

Press to clear this

condition.

Bargraph display does not

operate.

Instrument is in set mode. End set mode.

Power is not supplied.

Supply power of 85 to 264

VAC.

Fuse is blown.

Change it.

Bargraph and alphanumeric

displays are not illuminated.

Power supply or internal

circuit is faulty.

Ask NIDEC TOSOK for

repair.