Tools required, Purpose of evaporative cooling, Theory – Hired-Hand Mega-Cool rev 4-08 User Manual

Page 3: Description of unitized system

Part No. 4801-5093 Rev 4-08

Unitized System

Page 3

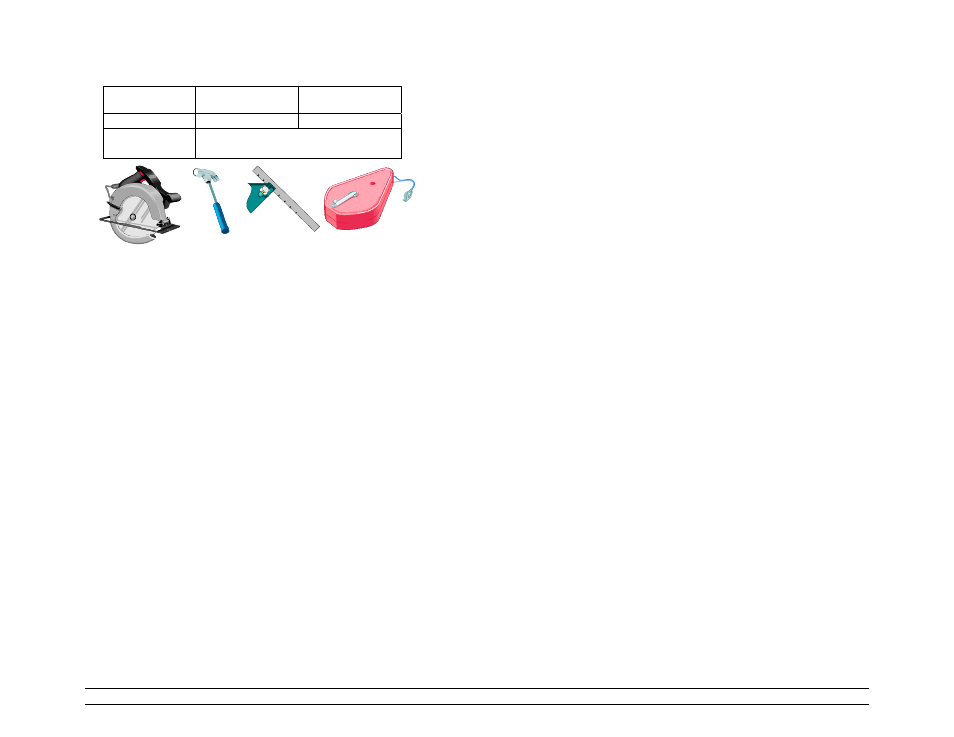

Tools Required

PVC piping

glue

PVC piping

cutter

Circular Saw

Level Chalk

Line Hammer

Wrench

Cordless drill with 1/4

″

nut driver

Purpose of Evaporative Cooling

Evaporative cooling is a time tested efficient means of reducing air

temperature by drawing incoming air across a wetted surface. Evaporative

cooling is especially useful in situations where air inside the space is not re-

circulated. The efficiency and the cooling ability evaporative cooling

possesses make evaporative cooling a wise choice for agricultural and

horticultural structures.

Theory

Evaporative cooling needs only two factors to work: water, and moving air.

When air is moved across a wet surface, some of the water on the surface

evaporates. This action draws heat from the moving air, cooling, and

humidifying the incoming air.

Description of Unitized System

The Unitized System combines the RollSeal

®

side wall curtain with an

evaporative cooling cell. The side wall curtain component is a motorized

curtain enclosure for the side of an agriculture or horticulture structure that

can regulate ventilation when connected to an automatic controller. The

evaporative cooling component is a row of evaporative cooling pads and

water that cools incoming air. In the unitized system, these components

mount in front of a single opening. This gives a system for regulating both

temperature and ventilation of a building. Since only one wall opening is

required for each system, this increases the efficiency and lowers operating

costs. The unitized system may be divided into individual groupings.

These groupings are defined by their collective purposes: curtain, reservoir,

fill line, pump kit, supply line, spray line, and pads.

Curtain

The complete side wall curtain assembly consists of adjacent

side wall curtain systems. Each system frames an opening and

provides a mount for supporting a drive pipe to which the

curtains are attached.

Reservoir

The reservoir serves a dual purpose. It holds the water supply

for the pump, and collects the water returning from the pads.

It consists of eight inch (20.3 cm) diameter PVC piping.

Fill line

The fill line supplies make-up water to the system.

Pump Kit

The pump kit includes the pump, shutoff valves, bleed off line,

and strainer. This section provides the force for moving water

from the reservoir to the supply line.

Supply line The supply line carries water from the pump kit to the spray

line. This section is made of one and a half inch (3.8 cm) PVC

piping and various fittings.

Spray line

The spray line is constructed of 1-1/4 inch diameter PVC pipe

with holes drilled in the line along the top. These holes are

drilled a certain distance apart depending on the size of pad

installed. When water is pumped to the spray line, water

shoots out the holes onto the distribution plate then drops into

the pads.

Pads

Constructed of cellulose fibers formed into corrugated blocks.

When water flows down the system, and air is drawn through

the pads, the air evaporates some of the water, becoming much

cooler. When the water reaches the bottom of the pads, it

drips back into the reservoir.