Parameter summary, Parameter summary -1 – Yokogawa EJX440A User Manual

Page 62

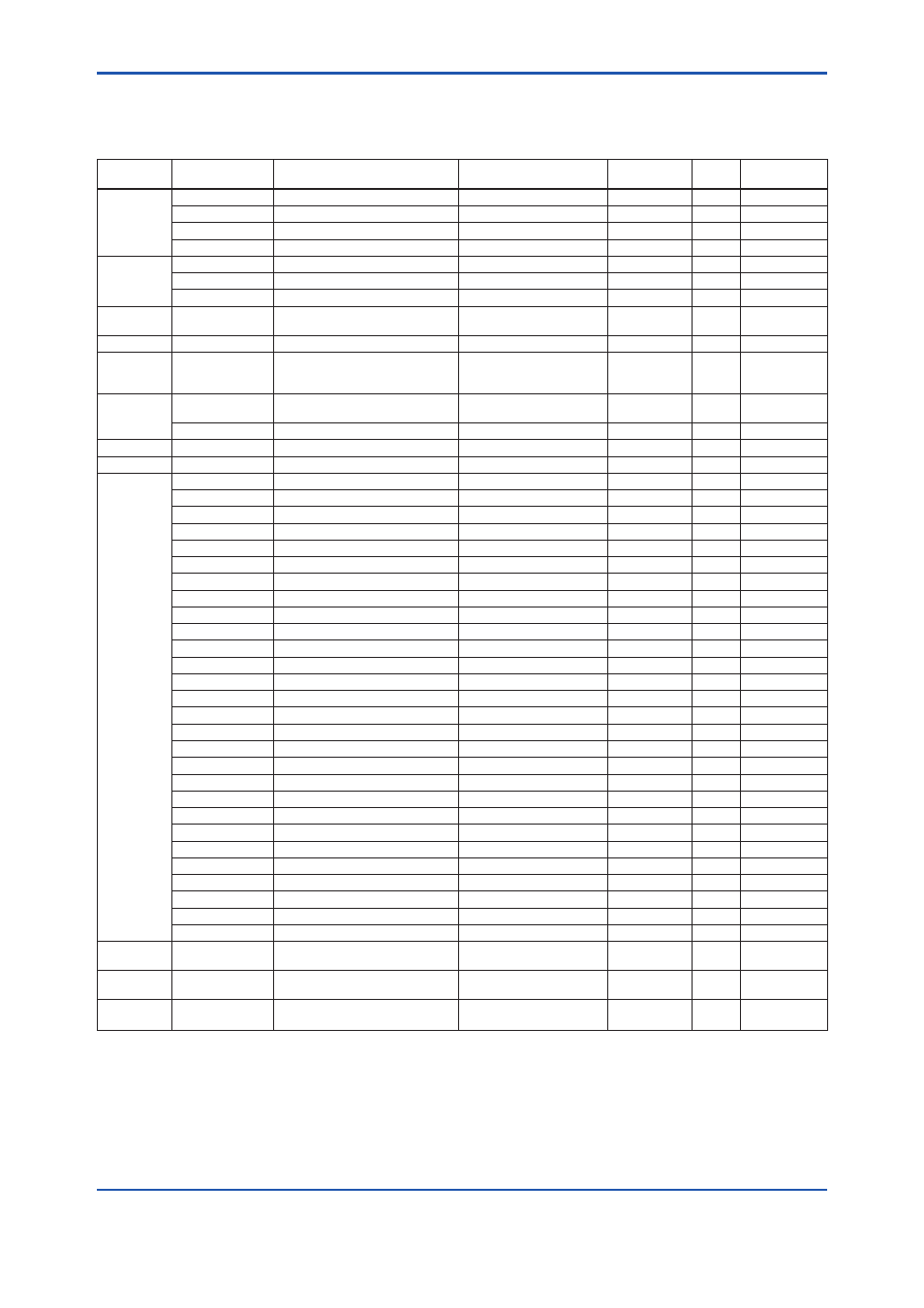

<5. Parameter Summary>

5-1

IM 01C25T01-01E

5. Parameter Summary

Function

Label

Item

Contents

Default value

Handling

Fast key

sequences

Analog output AO alm typ

Analog output alarm type

High or Low

R

1, 4, 3, 2, 5

AO lower limit

Lower limit of analog output

3.6000 to 21.6000 mA

3.6000 mA

W

1, 4, 3, 2, 7

AO upper limit

Upper limit of analog output

3.6000 to 21.6000 mA

21.6000 mA

W

1, 4, 3, 2, 8

Auto recover

Auto-recover from hardware error

Off or On

On

W

1, 4, 3, 2, 6

Analog output

trim

Clear D/A trim

Reset analog output trim

M

1, 2, 3, 2, 3

D/A trim

Analog output trim with ammeter

M

1, 2, 3, 2, 1

Scaled D/A trim

Analog output trim with voltmeter

M

1, 2, 3, 2, 2

Bi-directional

mode

Bi-dir mode

Bi-directional mode

Off or On

Off

W

1, 4, 2, 9

Burst mode

Burst mode

Burst mode

Off or On

Off

W

1, 4, 3, 3, 3

Burst

operation

option

Burst option

Burst option

PV, % range/current, or

Process vars/cmt

W

1, 4, 3, 3, 4

Damping

Pres Damp

Damping time constant at amplifier

0.00 to 100.00 sec

As specified or

2.00 sec

W

1, 3, 6

Quick resp

Quick response

On or Off

Off

W

1, 4, 2, ↓

Date

Date

Date

**/**/**

W

1, 3, 4, 1

Descriptor

Descriptor

Descriptor

16 alphanumerics

As specified

W

1, 3, 4, 2

Device

information

Dev id

Device ID

R

1, 4, 5, 1, ↓, 6

Distributor

Yokogawa

R

1, 4, 5, 1, ↓, 7

Drain vent matl

Drain and vent plug material

W

1, 4, 5, 2, 5

Extra No.

Customization number

R

1, 4, 5, 1, ↓, 4

Ext SW

External zeroing permission

Disabled or Enabled

Enabled

W

1, 4, 5, 1, 9

Fill fluid

Fill fluid

W

1, 4, 5, 2, 2

Final asmbly num

Final assembly number

W

1, 4, 5, 1, ↓, 5

Fld dev rev

Field device revision

R

1, 4, 5, 1, ↓, 2

Gasket matl

Gasket material

W

1, 4, 5, 2, 3

Isoltr matl

Capsule material

W

1, 4, 5, 2, 1

LSL

Lower sensor limit

R

1, 3, 3, 1, 4

Mftr Date

Manufactured date

R

1, 4, 5, 1, ↓, 3

Min span

Minimum span

R

1, 3, 3, 1, 6

Model 1

Memo field for MS code 1

32 alphanumerics

W

1, 4, 5, 1, 5

Model 2

Memo field for MS code 2

32 alphanumerics

W

1, 4, 5, 1, 6

Model 3

Memo field for MS code 3

32 alphanumerics

W

1, 4, 5, 1, 7

Num of RS

Number of remote seal

W

1, 4, 5, 2, 9

Process Conn matl Process connection material

W

1, 4, 5, 2, 4

Process Conn size Process connection size

W

1, 4, 5, 2, 8

Process Conn type Process connection type

W

1, 4, 5, 2, 6

RS fill fluid

Fill fluid of remote seal

W

1, 4, 5, 2, ↓

RS Isoltr matl

Remote seal material

W

1, 4, 5, 2, 7

RS type

Remote seal type

W

1, 4, 5, 2, ↓

Serial No.

Serial number

R

1, 4, 5, 1, ↓, 2

Software rev

Software revision

R

1, 4, 5, 1, ↓, 3

Style No.

Style number

Style number of product

R

1, 4, 5, 1, ↓, 1

Universal rev

Universal revision

R

1, 4, 5, 1, ↓, 1

USL

Upper sensor limit

R

1, 3, 3, 1, 5

Diag

Applicable

Diag Applicable

Appicable blockage detection

Disabled or Enabled

R, G

1, 2, 4, 3, 1, 2

Diag

DPComp

Diag DPComp

fDP compensation selection

0: Compensation or

1: Non-compensation

0:

Compensation

W, G

1, 2, 4, 3, 2, 7

Diag Error

Diag Error

Results detected by ILBD or Heat

trace monitoring

R, G

1, 2, 4, 1

*1:

Handling:

R=Read only, W=Read & Write, M=Method, A=Applicable for option code AL, G=Applicable for option code DG6,

D=Applicable for differential pressure transmitters. Do not change these parameters for pressure transmitters.

*2:

The default value shows MWP (Maximum working pressure) of the capsule.

Since the working pressure limit varies according to the Model, refer to the General Specifications section in each user’s manual.