Warning, Wall-mounting specification inverse specification – IAI America IX-UNN3515 User Manual

Page 58

52

6. Inspection/Maintenance

Warning

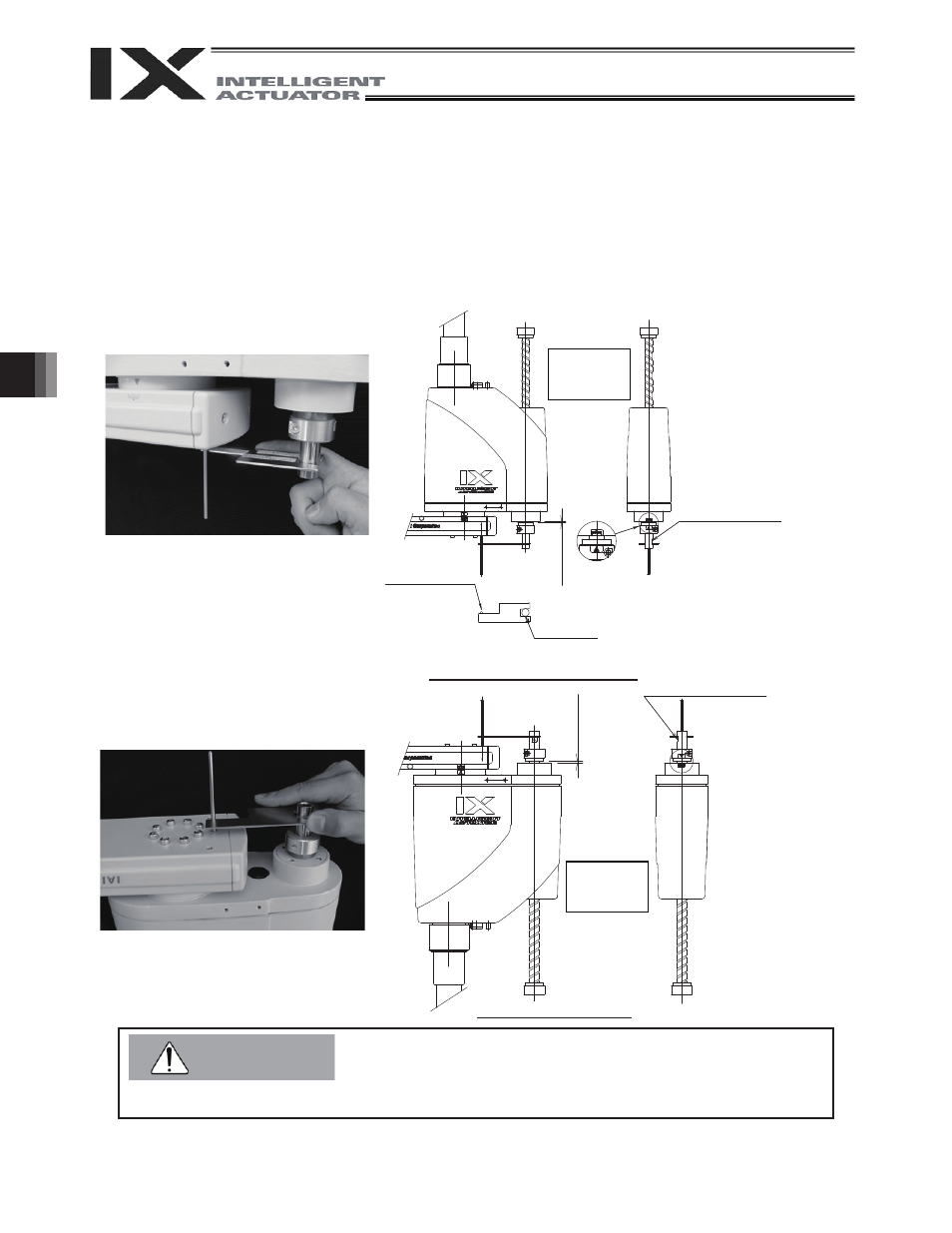

(8) Affix the rotational axis at the reference position by setting the plate and pin of the adjustment jig as illustrated

below.

Set the jig after confirming that the emergency-stop switch is pressed.

1)

Confirm that the rotational axis is roughly in the reference position. (Positioning marks for the rotational axis

should align. With the wall-mounting specification, the D-cut surface should be on the right side when

viewed from the front. With the inverse specification, the D-cut surface should be on the left side.)

2)

Set a plate jig on the rotational axis by causing its side labeled “UPPER” to face up (it should face down with

the inverse specification).

3)

Insert a pin jig from the bottom to set the rotating direction of arm 2.

4)

Turn the rotational axis until the plate jig contacts the pin lightly.

z Always press the emergency-stop switch before setting an adjustment jig. Failure to do so may cause the

robot to malfunction and result in a serious accident.

Reference

position

drawing

D-cut surface

Adjust so that a

clearance of

approx. 4 mm is

provided between

the stopper’s top

face and the

bottom face of

arm 2.

Cause the jig to lightly

contact the pin.

Down view

Positioning

mark label for

rotational axis

D-cut surface of the

rotational axis should be

on the right side when

viewed from the front.

Wall-mounting specification

Inverse specification

Reference

position

drawing

Appr

ox. 4

m

m

D-cut surface of the

rotational axis should be

on the left side when

viewed from the front.

Appr

ox. 4

m

m