Caution – IAI America IX-UNN3515 User Manual

Page 32

26

5. Precautions for Use

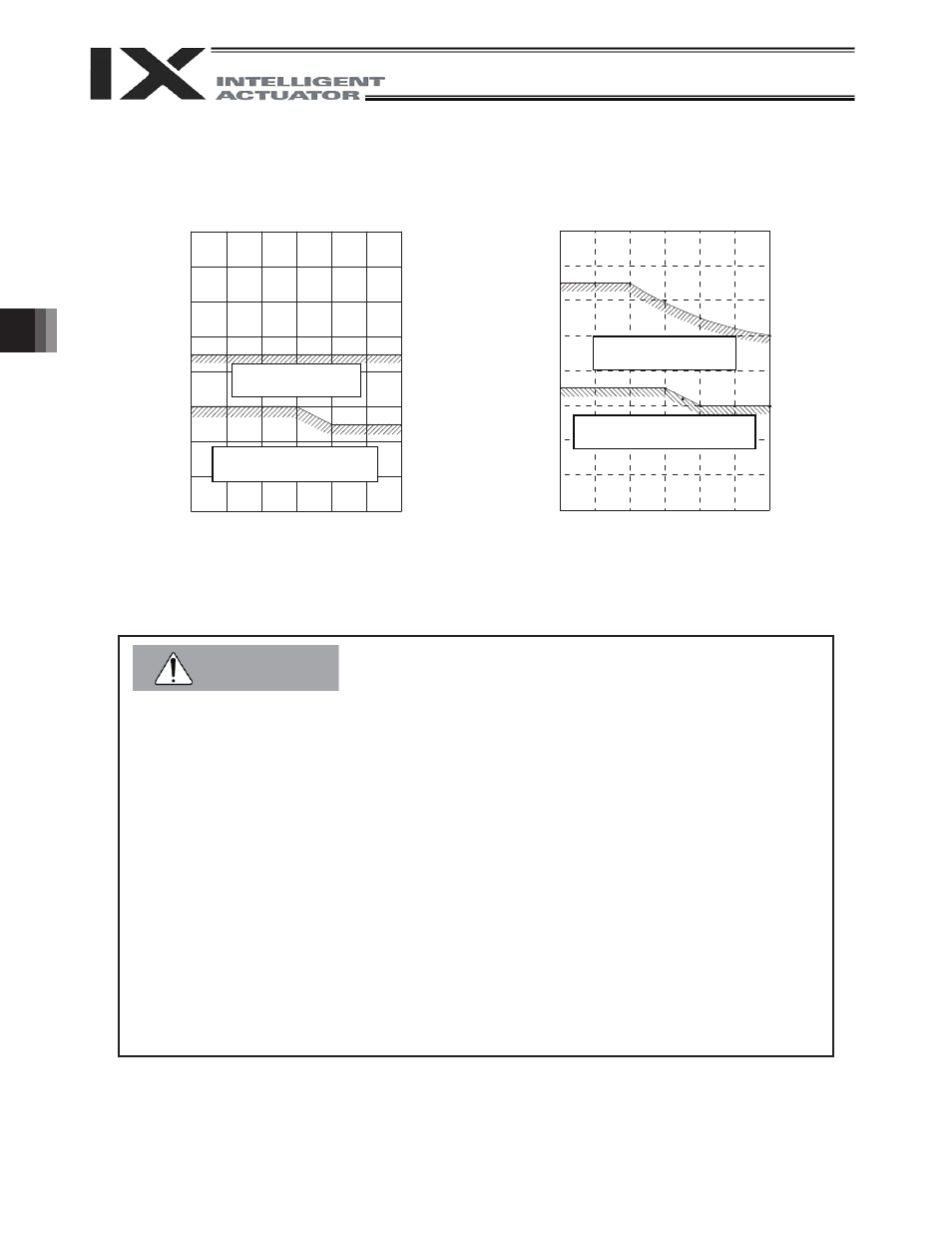

(2) CP operations (Use the ACC/DCL instructions of the SEL language for setting.)

z To operate the robot at the maximum acceleration/deceleration, provide a stopping period of three

seconds or more after each acceleration/deceleration.

z Start from the appropriate reference setting for acceleration/deceleration during continuous

operation, and then gradually raise the value for the purpose of adjustment.

z If an overload error occurs, lower the acceleration/deceleration setting as appropriate or provide

an appropriate stopping time following each acceleration/deceleration.

z Depending on the position of the vertical axis, the robot may generate vibration when axis 1, axis

2 or the rotational axis turns. If vibration occurs, lower the acceleration/deceleration as

appropriate.

z To move the robot horizontally at high speed, keep the vertical axis as close as possible to the top

position. If the vertical axis is operated at the bottom position, the spline shaft for the ball screw

will bend and the vertical axis will be disabled.

z Keep the permissible moment of inertia of axis 4 to 0.015 kgm or less.

z The carrying load indicates a load above the rotational center of axis 4.

z Operate the robot by using an appropriate acceleration/deceleration coefficient as determined by

the mass of the positioning precision. Failure to do so may cause the drive part to wear

prematurely or may result in damage or vibration.

1.6

1.2

0.8

0.4

0

0

1

2

3

0

1

2

3

1.6

1.2

0.8

0.4

0

Arm length 300

Reference acceleration/deceleration

settings for CP operation

Arm length 300

Reference acceleration/deceleration

settings for CP operation

Reference range of

maximum setting

Reference range of

maximum setting

Accel

eration/

deceleration (G)

Carrying load mass (kg)

Reference range for

continuous operation setting

Accel

eration/

deceleration (G)

Carrying load mass (kg)

Reference range for continuous

operation setting

Caution