3 absolute encoder reset method, Warning – IAI America IX-UNN3515H User Manual

Page 60

54

13. Inspection/Maintenance

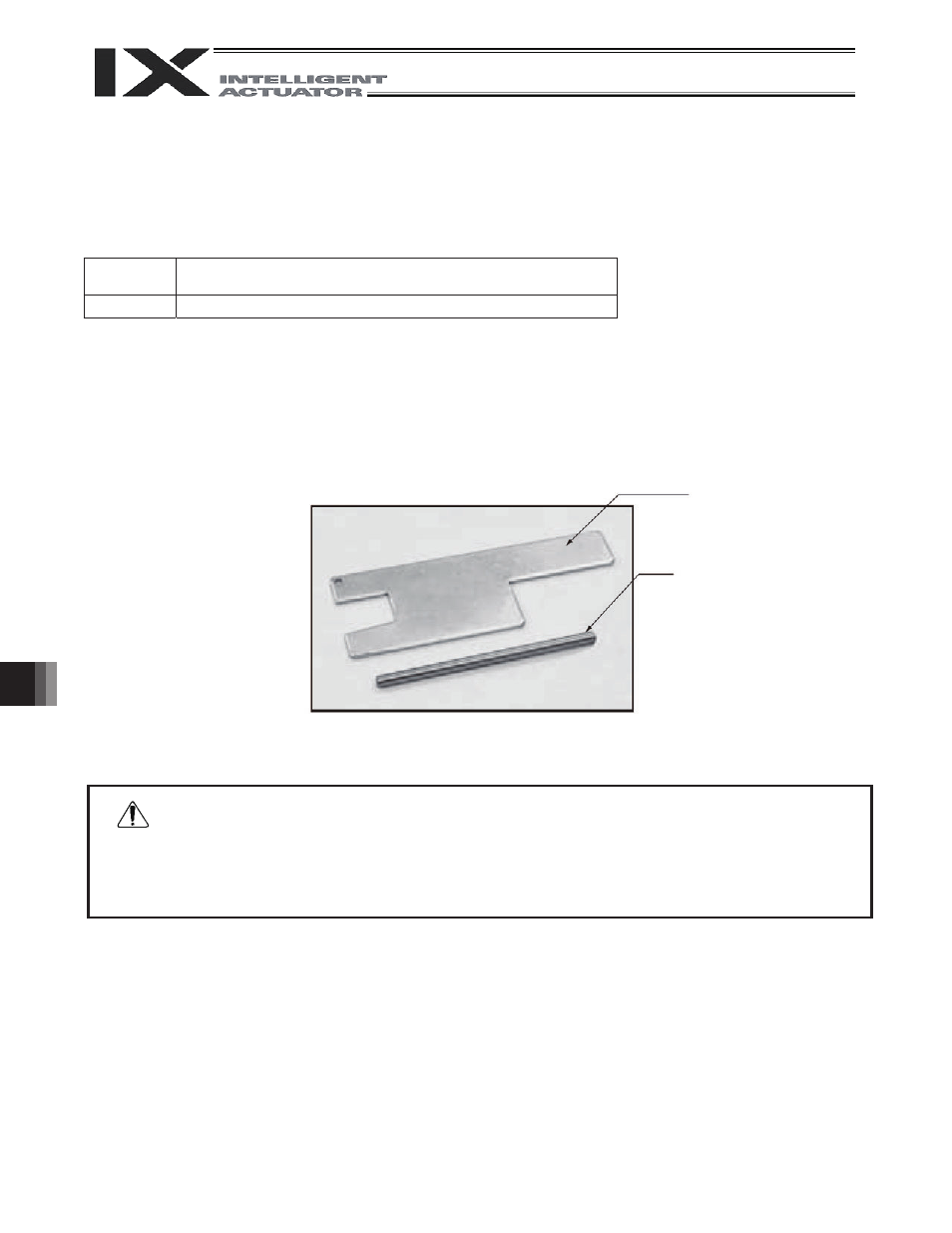

Plate

Pin

13.3 Absolute Encoder Reset Method

13.3.1 Preparation for Absolute Reset

The following jigs are required to perform an absolute reset.

x Absolute reset adjustment jigs

Model

number

Remarks

JG-2

For arm length 250/300/350

Connect the robot, controller and PC cables so that the robot/controller can be operated using the PC software.

Be sure to check the EMG switch operation beforehand.

An absolute reset of the rotational and vertical axes requires absolute reset adjustment jigs, but jigs are not

always required for an absolute reset of arms 1 and 2.

(A multi-rotation reset can be performed as long as the current position is within

r1 graduation on the positioning

mark sticker.)

Example of Absolute Reset Adjustment Jig (Model number JG-1)

z Fully understand the applicable inspection/maintenance work, because failure to do so may result in a

serious injury accident.

z Put up a “WORK IN PROGRESS” sign to prevent other operators from accidentally operating the

controller, operation panel, etc. Remember to insert the seal washer

Warning