2 installation of main unit – IAI America RCP4-RA6R User Manual

Page 43

2. Installation

37

2.3.2

Installation of Main Unit

The surface to mount the main unit should be a machined surface or a plane that possesses an equivalent

accuracy and the flatness should be within 0.05mm. Also, the platform should have a structure stiff enough to

install the unit so it would not generate vibration or other abnormality.

䎃

Also consider enough space necessary for maintenance work such as actuator replacement and inspection.

On the base there is a datum surface prepared for the attachment slotted holes.

On the back side of the actuator, there are attachment tapped holes, through holes, positioning reamed holes and

slotted holes. For the details of the positions and dimensions, check in the appearance drawings. [Refer to 6.

External Dimensions.]

When repeatability in re-attaching is required after it is detached, utilize the reamed holes. Please note, however,

that a consideration is necessary such as to use only one point on the motor side of the reamed holes when a

fine-tuning such as perpendicularity is required.

[1] Using the Tapped Holes on the Bottom of the Base

䎃

This actuator has tapped holes for mounting so it can be fixed from the bottom of the base.

(Note that the tapped hole size depends on the model. Please see the diagrams below and 6. “External

Dimensions.”)

Also, there are reamed holes and a slotted hole for positioning pins.

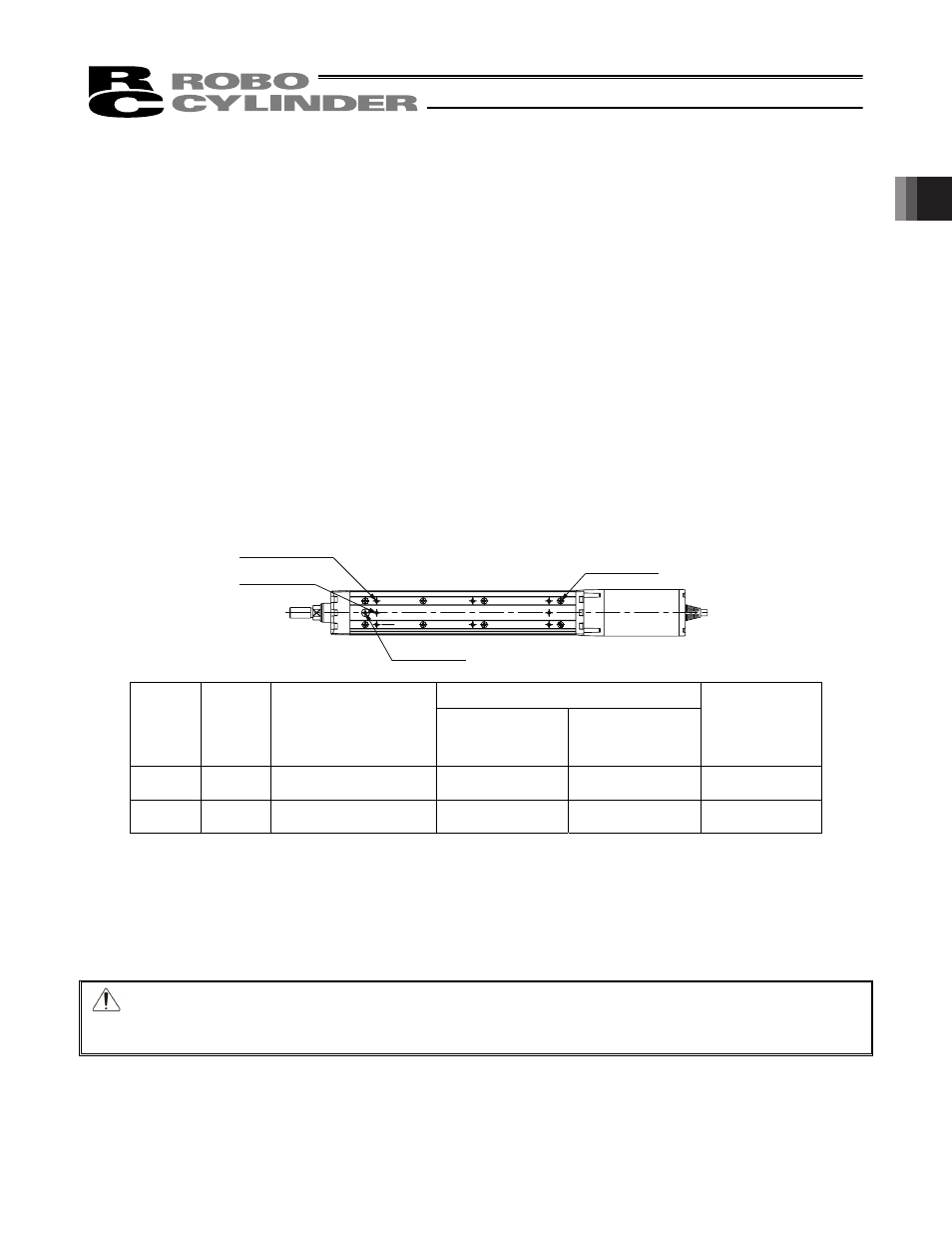

Oblong Hole

Reamed Hole

Attachment Hole

Through Hole

Tightening Torque

Model

Name

Tapped

Hole Size

Tapped Holes Depth

In the case that steel

is used for the bolt

seating surface:

In the case that

aluminum is used for

the bolt seating

surface:

Reamer Hole [mm]

RA5C

RA5R

M4

7mm

3.59N㨯m

(0.37kgf㨯m)

1.76N㨯m

(0.18kgf㨯m)

I

4H7 Depth 5.5

RA6C

RA6R

M5

9mm

7.27N㨯m

(0.74kgf㨯m)

3.42N㨯m

(0.35kgf㨯m)

I

4H7 Depth 5.5

Tightening screws

x

Use hexagonal socket head bolts for the male threads for installing the base.

x

Use of high–tension bolts meeting at least ISO 10.9 is recommended.

x

The length of thread engagement should be 1.8 times more than the nominal diameter, and pay attention not to

stick the screw out inside the actuator.

Caution: Be careful when selecting the bolt length. If bolts of inappropriate lengths are used, the tapped

holes may be damaged, actuator mounting strength may become insufficient, or contact with

driving parts may occur, resulting in lower precision or unexpected accidents.