Maintenance/inspection, 1 inspection items and timings, Warning – IAI America RCP2-RTCBL User Manual

Page 56

48

10. Maintenance/Inspection

10. Maintenance/Inspection

Daily and periodic inspections are essential to making sure your actuator will operate safely and efficiently.

Before carrying out each inspection, check the applicable maintenance/inspection items listed below.

10.1 Inspection Items and Timings

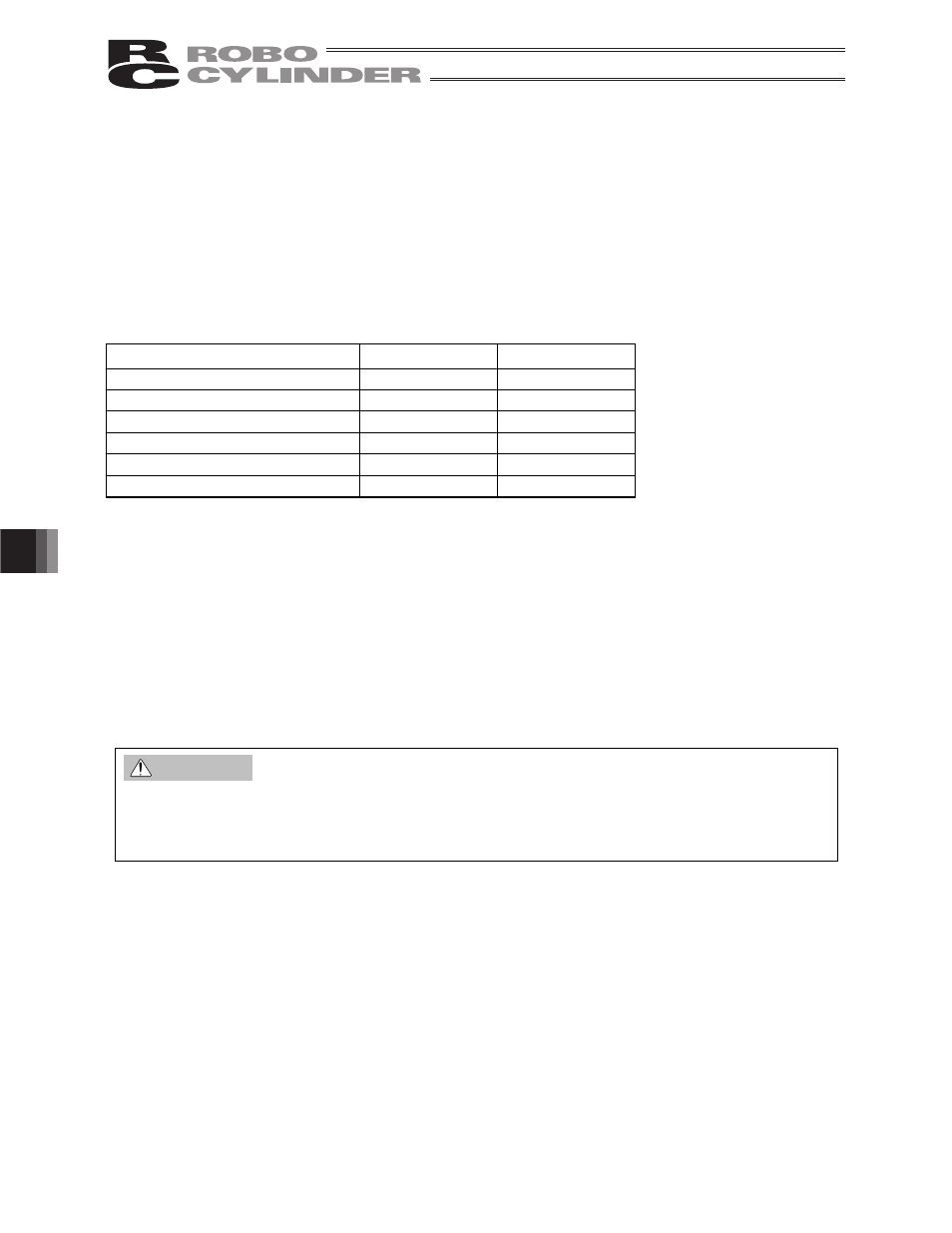

Conduct visual inspection and add grease at the applicable timings specified below.

The following schedule is based on eight hours of operation daily. If the actuator is operated at a higher

utilization rate, including when it is operated continuously day and night, shorten the inspection intervals

as necessary.

Visual inspection

Grease supply

At startup inspection

{

1 month after start of operation

{

6 months after start of operation

{

1 year after start of operation

{

{

Every 6 months thereafter

{

Every year thereafter

{

{

* Any adjustments requiring the following operations must be carried out at our factory. Do not

disassemble the actuator or cut any of its cables in the location where the actuator is installed.

Disassemble the motor

Disassemble the gear

Disassemble the bearing

Cut a cable

If the user has disassembled any of the above components or cut any of the actuator’s cables, IAI will not

be responsible for any malfunction or problem that may occur thereafter.

Warning

x Performing inspection or maintenance work without a thorough understanding of the specific tasks

involved may result in a serial accident.

x If inspection is not carried out regularly, the drive part may reach its life prematurely or the actuator

may suddenly start malfunctioning.