IAI America RCP2-BA7U User Manual

Page 57

4. Maintenance Inspection

51

4.8.2 BA6U/BA7U (Motor at the Bottom)

[Items Required for Replacement]

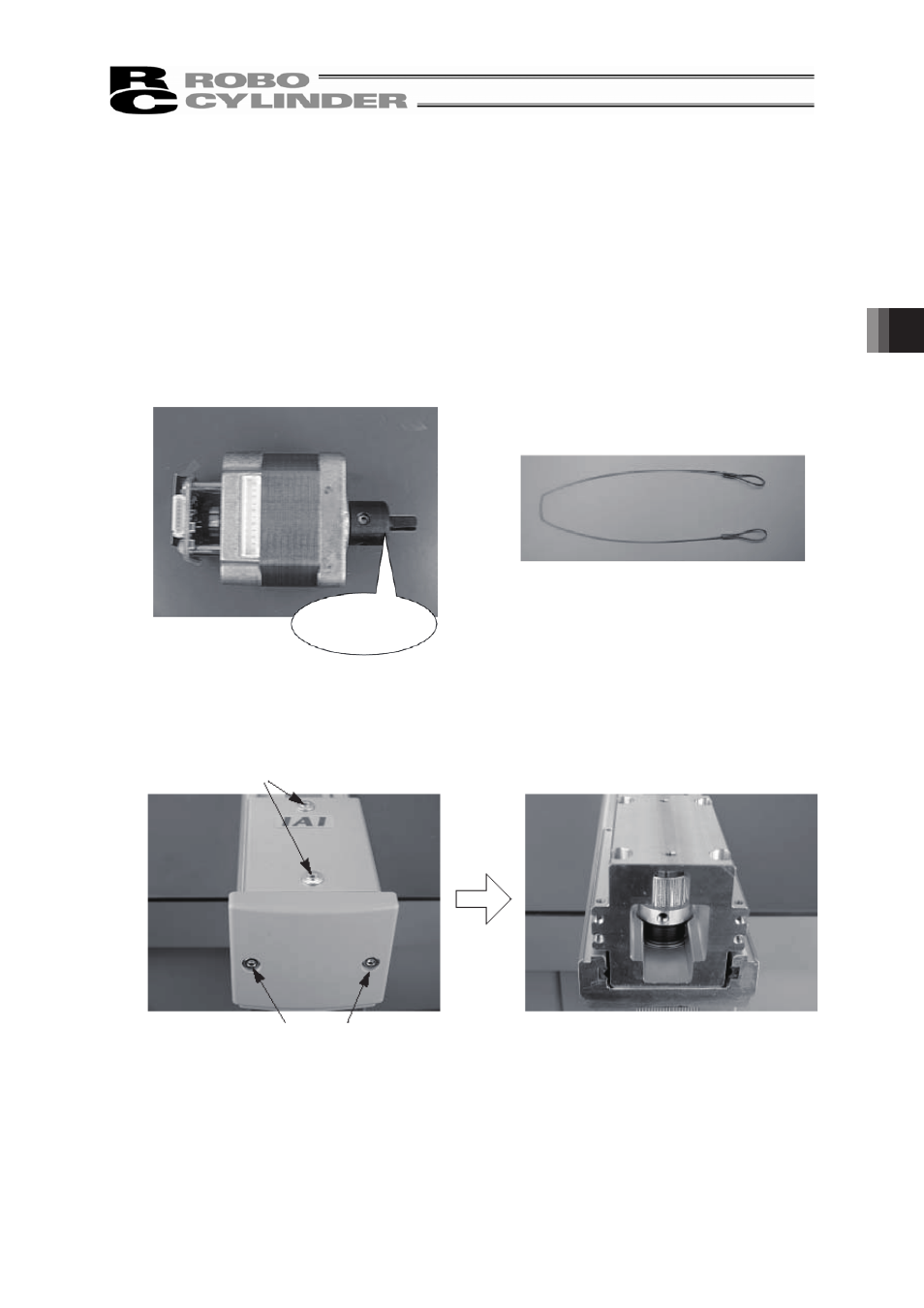

• Replacement motor (with the motor shaft preassembled with a joint hub: see photograph 1))

• Tension adjustment wire (provide a commercially available wire like the one shown in photograph 2))

• Setscrew (M4 × 5, flat-tip, precoated)

• Setscrew (M4 × 5, recessed-tip, precoated)

• 1.5mm thick spacer (or thickness gauge)

• Phillips screwdriver set and hex wrench set

• Tension gauge (capable of applying a tensile load of 12kgf or more)

• Grease (Kyodo Yushi’s Multemp LRL3 or equivalent)

• Hot gun (used if the setscrews do not come off)

[Photograph 1)]

[Photograph 2)]

Joint hub

[Procedure]

1) First, remove the drive belt.

Remove the load from the slider and follow steps 1) to 7) in 4.7.4, “Replacing the Belt,” to remove

the belt.

2) Remove the bracket and rear cover.

Use a hex wrench of 1.5mm across flats.

Use a hex wrench of 2.5mm across flats.