3 checking and adjusting the belt tension – IAI America RCP2-BA7U User Manual

Page 45

4. Maintenance Inspection

39

4.7.3 Checking and Adjusting the Belt Tension

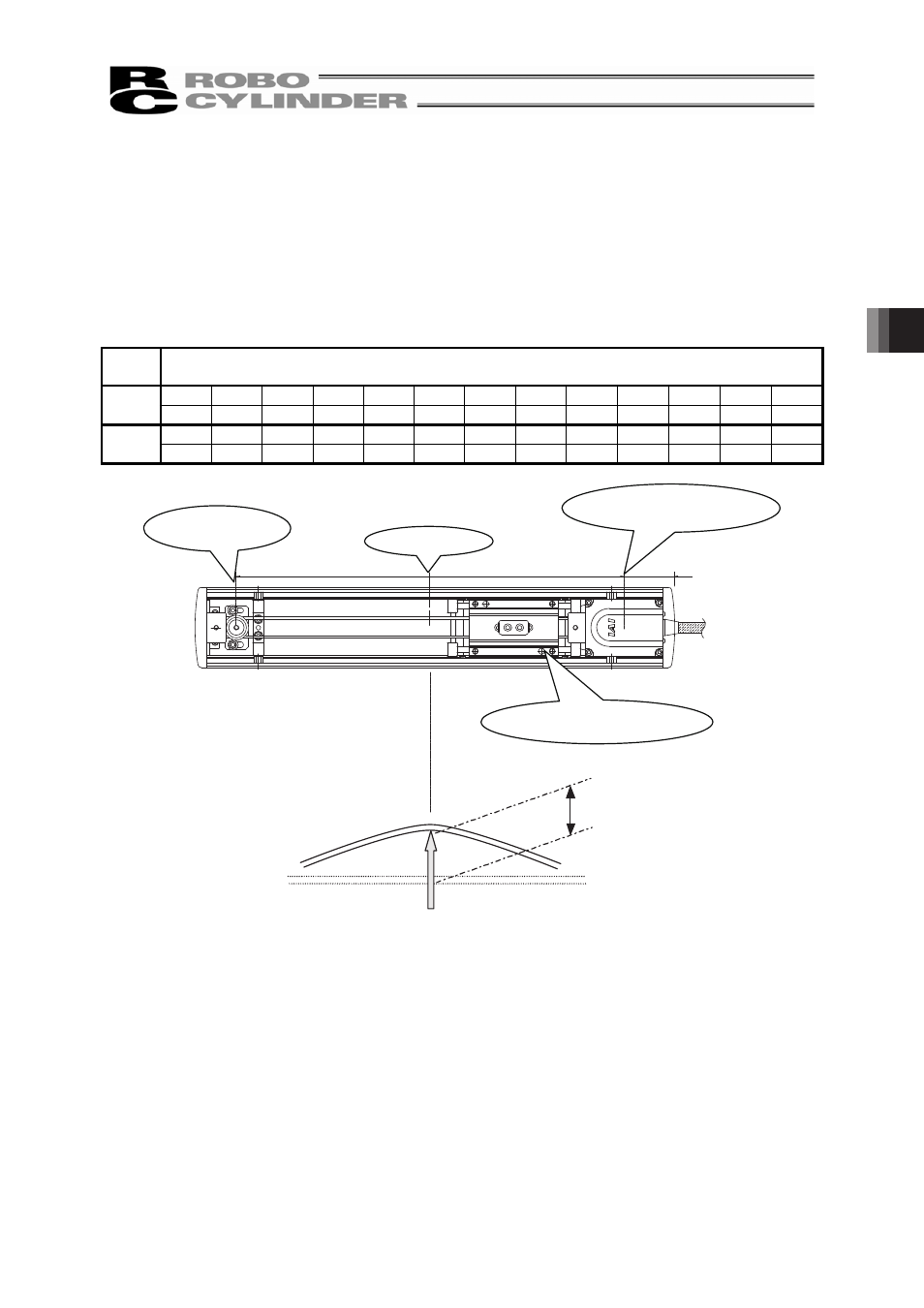

[1] Checking the Tension

As a guideline, belt tension is evaluated by the load needed to deflect the belt by 10mm when the

belt is pushed near the stroke center.

The table below lists the appropriate loads needed to achieve a 10mm deflection on each belt used

at different strokes.

If the measured load is less than the applicable value by approx. 20% or more, the belt is loose

and its tension must be adjusted.

Appropriate loads to achieve 10mm deflection

Model

Top: Stroke (mm)

Bottom: Load (kgf)

500 550 600 650 700

750

800

850

900

950 1000

-

-

BA6

BA6U 0.32 0.31 0.31 0.30 0.35 0.35 0.34 0.34 0.40 0.40 0.39

-

-

600 650 700 750 800

850

900

950

1000 1050 1100 1150 1200

BA7

BA7U 0.37 0.36 0.35 0.35 0.41 0.40 0.40 0.39 0.39 0.45 0.45 0.44 0.44

Front stroke end:

Pulley center

Stroke center

Motor-side stroke end:

45mm forward of end face

Move the slider to the motor-

side mechanical end.

Deflection: 10mm

F: Load

45mm