Harrington Hoists and Cranes RHN - Rhino Wire Rope Hoist User Manual

Page 67

67

Table 7-1

Troubleshooting Guide

Symptom

Cause

Remedy

Overheating

Wrong voltage or

frequency

Check voltage and frequency of power supply against the rating

on the nameplate on the motor.

Brake drags

Check motor brake adjustment for proper clearance.

Extreme external

heating

Above an ambient temperature of 104°F, the frequency of hoist

operation must be reduced to avoid overheating of the motor.

Special provisions should be made to ventilate the hoist or

otherwise shield it from the heat.

Hoist and/or Trolley

operates intermittently

Contactor contacts

arcing

Check for burned contacts. Replace as needed.

Loose connection in

circuit

Check all wires and terminals for bad connections. Replace as

needed.

Broken conductor in

Pendant Cord

Check for intermittent continuity in each conductor of the Pendant

Cord. Replace entire Pendant Cord if continuity is not constant.

Trolley making loud

noise.

Trolley wheel

maladjusted on beam

Readjust the gap between the trolley wheel flange and the beam

flange.

Trolley will not move

Trolley wheel spacing

on beam too tight

Readjust the gap between the trolley wheel flange and the beam

flange.

Hoist is in highest hook

position

Lower bottom hook block until motion is possible again.

Abnormal noise from

wire rope and/or drum

Lack of lubrication,

worn wire

rope/drum/sheaves

Lubricate or replace wire rope/drum/sheaves

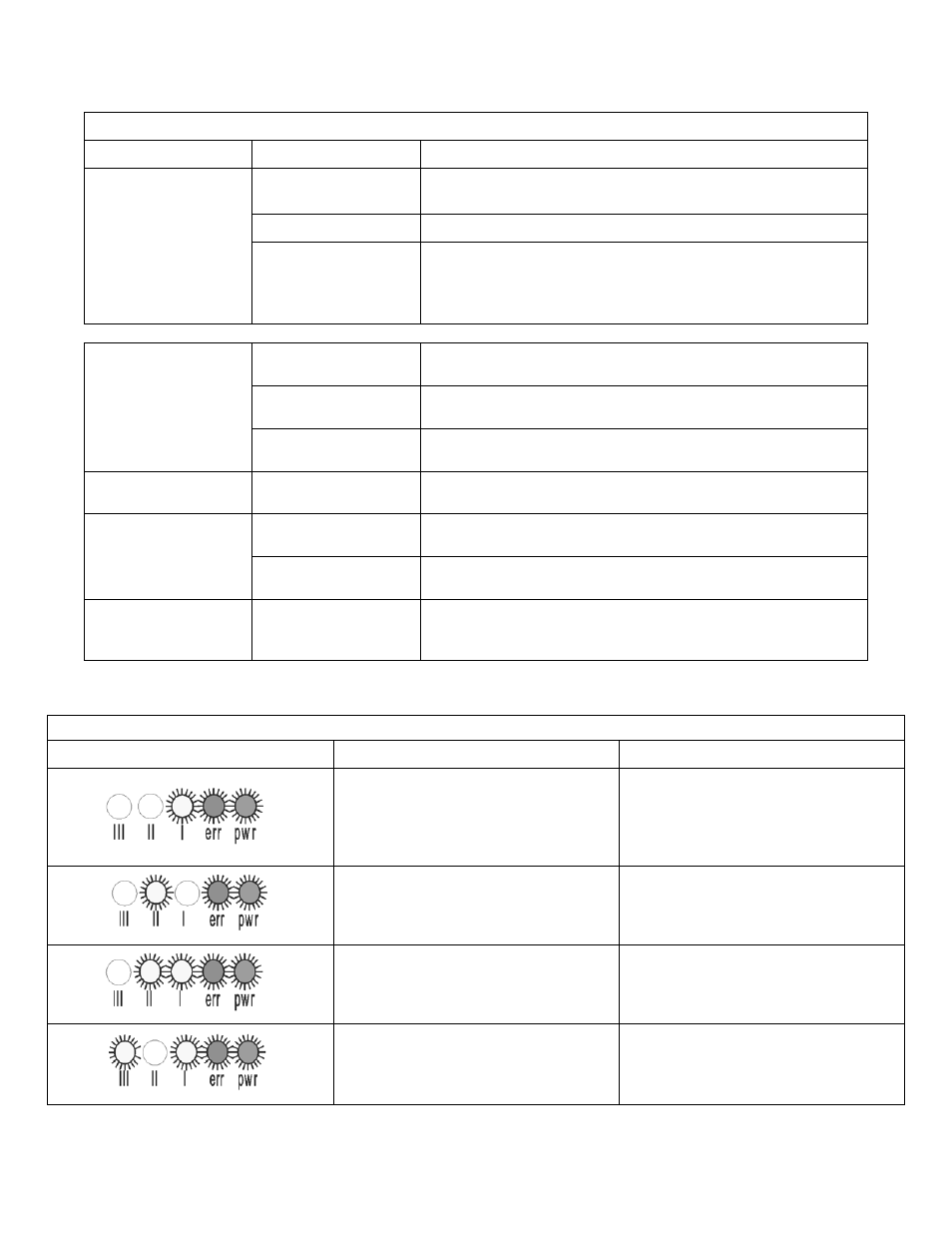

Table 7-2

Load Monitoring Device Error Code Guide

LED Error Code

Cause

Remedy

Sensor current <1mA or >24mA

• Check voltage supply

• Check sensor current (terminal 21)

• Check sensor cable

• Replace sensor

Overload

• Remove load from hoist

Over temperature (hoisting motion not

possible)

• Allow motor to cool down – check

PTC thermistors

Control error

• Check wiring (Lifting terminal 3 and

lowering terminal 4 are activated

simultaneously)