Harrington Hoists and Cranes RHN - Rhino Wire Rope Hoist User Manual

Page 45

45

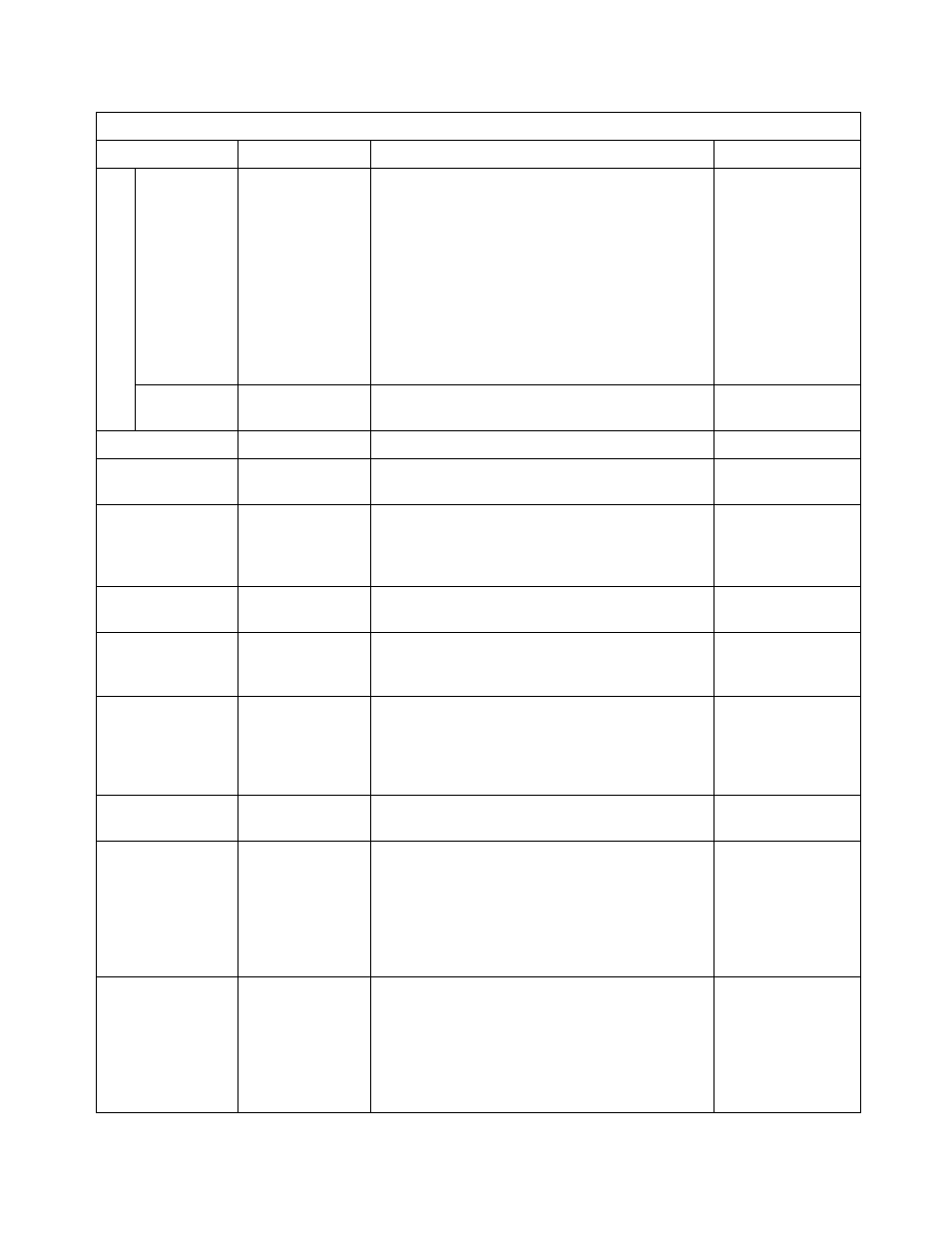

Table 5-5

Hoist (and Trolley) Inspection Methods and Criteria (continued)

Item

Method

Criteria

Action

Wire Rope -

Twisting

Visual

Run the hoist into the highest and lowest

hook positions without load.

If any twisting is detected , untwist the rope

immediately. See

Section 6.6

“Reeving and

Adjustments” and

Section 6.5

“Wire Rope

Removal”

Inspect the condition of the rope (especially

near pulleys and rope anchorage. See

Table

5-5

“Wire Rope- Condition”, “Wire Rope –

Diameter”, “Wire Rope-Broken Wires or

Strands”)

Replace as

required.

Wire Rope -

Lubrication

Visual

The wire rope must be maintained in a clean and

well lubricated condition.

Clean/lubricate

(see

Section 6.2

).

Trolley Side Plates

Visual

Must be free of significant deformation

Replace

Trolley Wheel –

Condition

Visual

Trolley Wheel should be free of significant wear,

cracks, nicks and gouges.

Replace.

Trolley Wheel –

Tread

Visual, Measure

The diameter and width of the tread surface

should not be less than the values listed in

Table

5-10

.

The diameter should not be less than 5% of

its original diameter as new.

Replace.

Trolley Wheel –

Gear

Visual

Teeth should not be cracked, damaged, or

excessively worn.

Replace.

Load Bar

Visual, Measure

Load Bar should be free of significant wear,

cracks, nicks and gouges. Load Bar should not

be bent.

Replace.

Trolley Motor

Brake

Visual

Braking action should not be overly abrupt and

should not allow excessive drift.

The brake disc

(brake rotor) should not exceed the maximum

permissible air gap (S) values listed in

Table 5-

11

.

Replace.

Contactor

Contacts

Visual

Contacts should be free of significant pitting or

deterioration.

Replace.

Sheaves

Visual

Sheave should be free of significant wear. The

wall thickness, t, should not be less than the “t

min” values in

Table 5-9

.

The groove depth, h,

should not be greater than the “h max” values

listed in

Table 5-9

.

They should also be checked

for easy running, indicating that the ball bearings

are in good condition.

Replace.

Pendant –

Switches

Function

Depressing and releasing push buttons should

make and break contacts in switch contact block

and result in corresponding electrical continuity or

open circuit. Push buttons should be interlocked

either mechanically or electrically to prevent

simultaneous energizing of circuits for opposing

motions (e.g. up and down, forward and reverse).

Repair or replace

as necessary.