Harrington Hoists and Cranes RHN - Rhino Wire Rope Hoist User Manual

Page 58

58

6.5.3

After commissioning a new wire rope hoist, or after replacing the rope, the rope of multi-fall hoists may

twist. This can be seen from the bottom hook block turning, particularly when unloaded.

Twisting in the rope prejudices safety and service life. Remove any twists!

Regularly inspect the rope for twisting and follow the procedure in

Table 5-5

“Wire Rope-Twisting” and

other corresponding Wire Rope sections in

Table 5-5

.

6.5.4

Wire Rope Removal/Rope Guide Replacement

1)

The hoist must be properly powered and operational in order to perform the following

procedures.

2)

When replacing Wire Rope, check for wear on mating parts, i.e. Drum, Sheaves, Hook

Block Sheaves and replace if necessary.

3) Lower the Hook Block to the lowest possible position without touching the floor or ground.

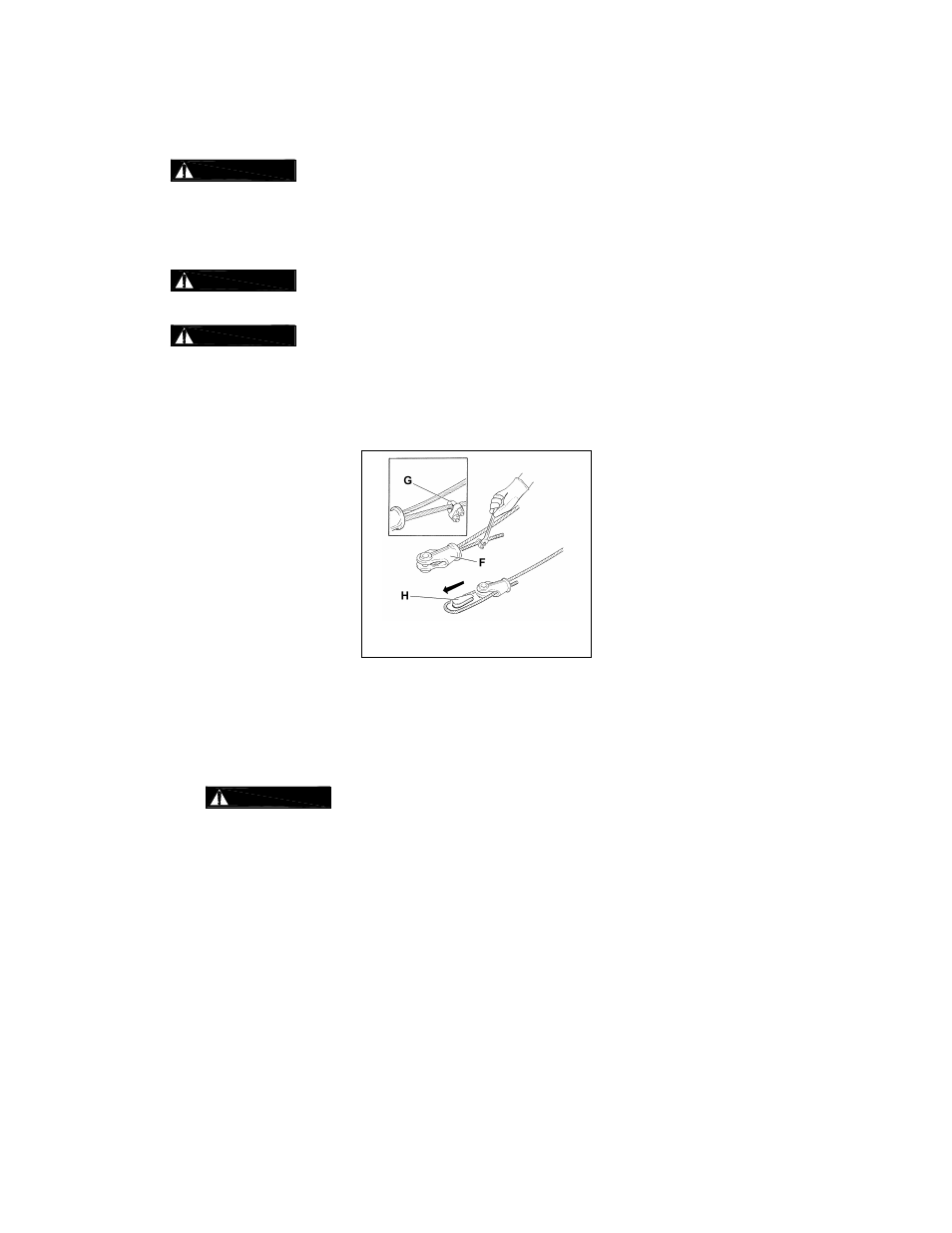

4) Remove the Wire Rope Clamp (G) and loosen the Wire Rope until the Terminal Wedge (H) can be removed

from the Anchorage Assembly (F) (see

Figure 6-4

).

Figure 6-4

5) Remove (unreeve) the Wire Rope from the Bottom Block and all Sheaves.

6) Remove the rope guide

Unscrew protective plate (1) under the rope drum at points (a). The rope guide can then be rotated freely.

For RHN02-RHN10 models see

Figure 6-5

; for RHN15 & RHN20 models see

Fig 6-6.

Danger of bodily injury or material damage - Do not unscrew stop with bearing

(2)! The stop with bearing (2) is locked with a conical spring washer. This must be refitted correctly.

See

Figure 6-5.

Unscrew screws (3). See

Figure 6-7.

Remove half-rings.

Unhook rope tensioning spring.

7) Unscrew the fixing screws in the clamping plates on the rope drum (see

Figure 6-8

)