Harrington Hoists and Cranes RHN - Rhino Wire Rope Hoist User Manual

Page 44

44

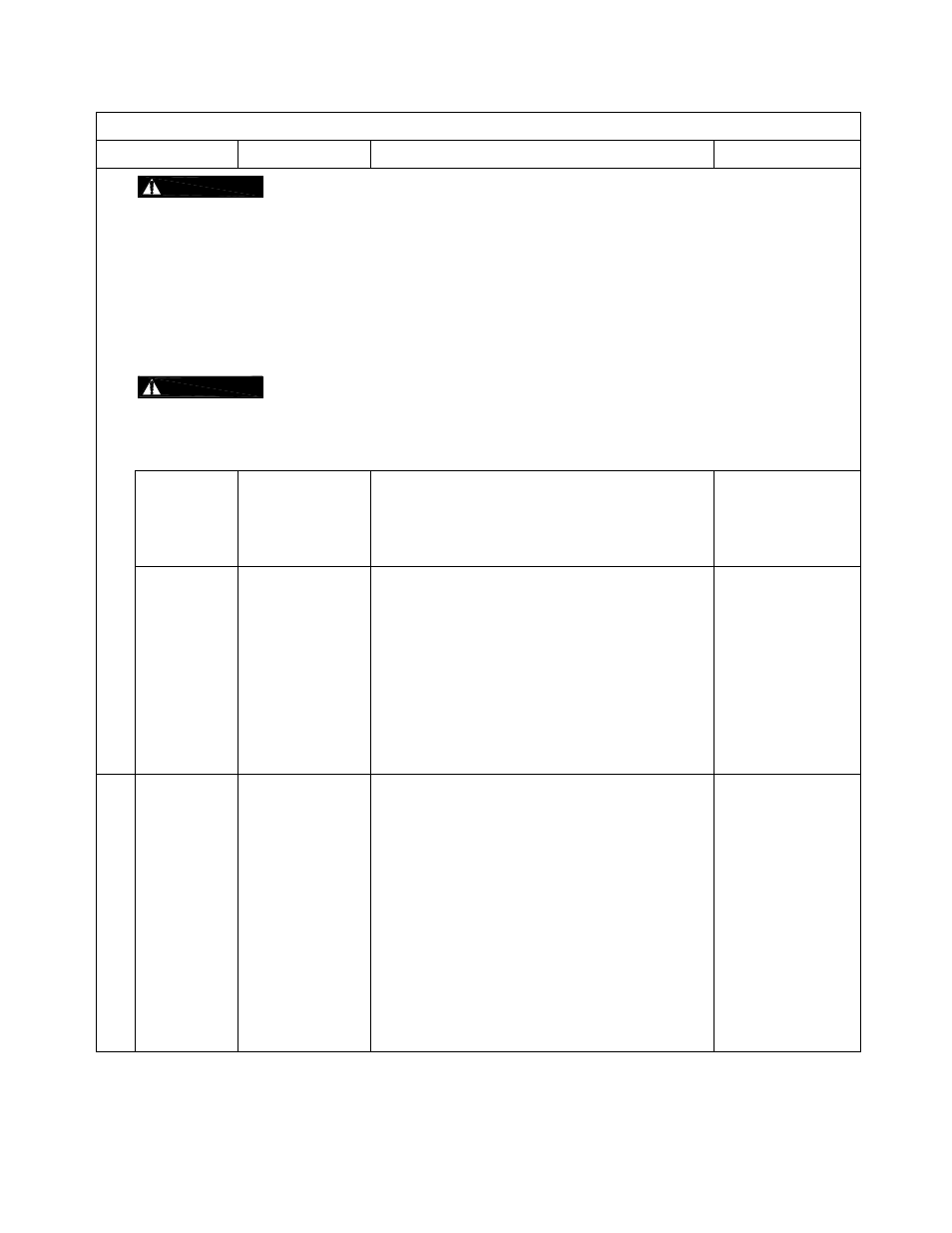

Table 5-5

Hoist (and Trolley) Inspection Methods and Criteria (continued)

Item

Method

Criteria

Action

The full length of the Wire Rope must be inspected for rope diameter, broken strands or

wires, and condition. The rope must be free of load for testing to detect any broken wires when bending the

rope by hand (especially by radius of rope sheeve). Special care should be taken when inspecting sections

of rapid deteriation, such as the following:

sections in contact with saddles, equalizer sheaves, or other sheaves where the rope travel is limited;

sections of the rope at or near terminal ends where corroded or broken wires may protrude;

sections subject to reverse bends;

sections of rope that are normally hidden during visual inspection, such as parts passing over sheaves.

In certain applications (constant deadweight, recurrent stopping position, automatic

operation, etc.) wire fractures may occur inside the rope without being visible from outside.

Any condition that could degrade the strength and performance of the wire rope must be reported to a

qualified person for evaluation and disposition.

Wire Rope

Diameter

Measure, Visual

Any reduction in the diameter of the wire rope

must not be reduced due to corrosion, wear or

core collapse more than the discard value in

Table 5-7

. The outer wires should not be worn

more than 10% of their original diameter.

Replace. Inspect

drum and all

sheaves.

Wire Rope –

Broken

Wires or

Strands

Visual

The wire rope should be inspected for broken

wires or strands, paying close attention to end

connection and sections that frequently pass over

sheaves. The rope must NOT have:

More than the Maximum number of broken

wires listed in

Table 5-7

.

More than 4 broken wires in 1 strand in one

lay (one full revolution of a strand around the

rope).

Any broken strands.

Replace

Wire Rope –

Condition

Visual

Any wire rope deformation with permanent

bends, flattening, unraveling, birdcaging, etc.

General corrosion.

Rope core exposure.

One or more loose or protruding strands or

wires from rope.

Severely corroded or broken wires at end

connections.

Severely corroded, cracked, bent, worn or

improperly applied end connections

Any evidence of heat damage of any kind.

(Wire rope exhibits any heat discoloration or

localized loss of lubrication).

Replace