Fault diagnosis with test functions, Teledyne analytical instruments 253 – Teledyne GFC-7001T - Trace CO Analyzer User Manual

Page 253

Troubleshooting and ServiceTeledyne API – Model T300/T300M CO Analyzer

Teledyne

Analytical

Instruments

253

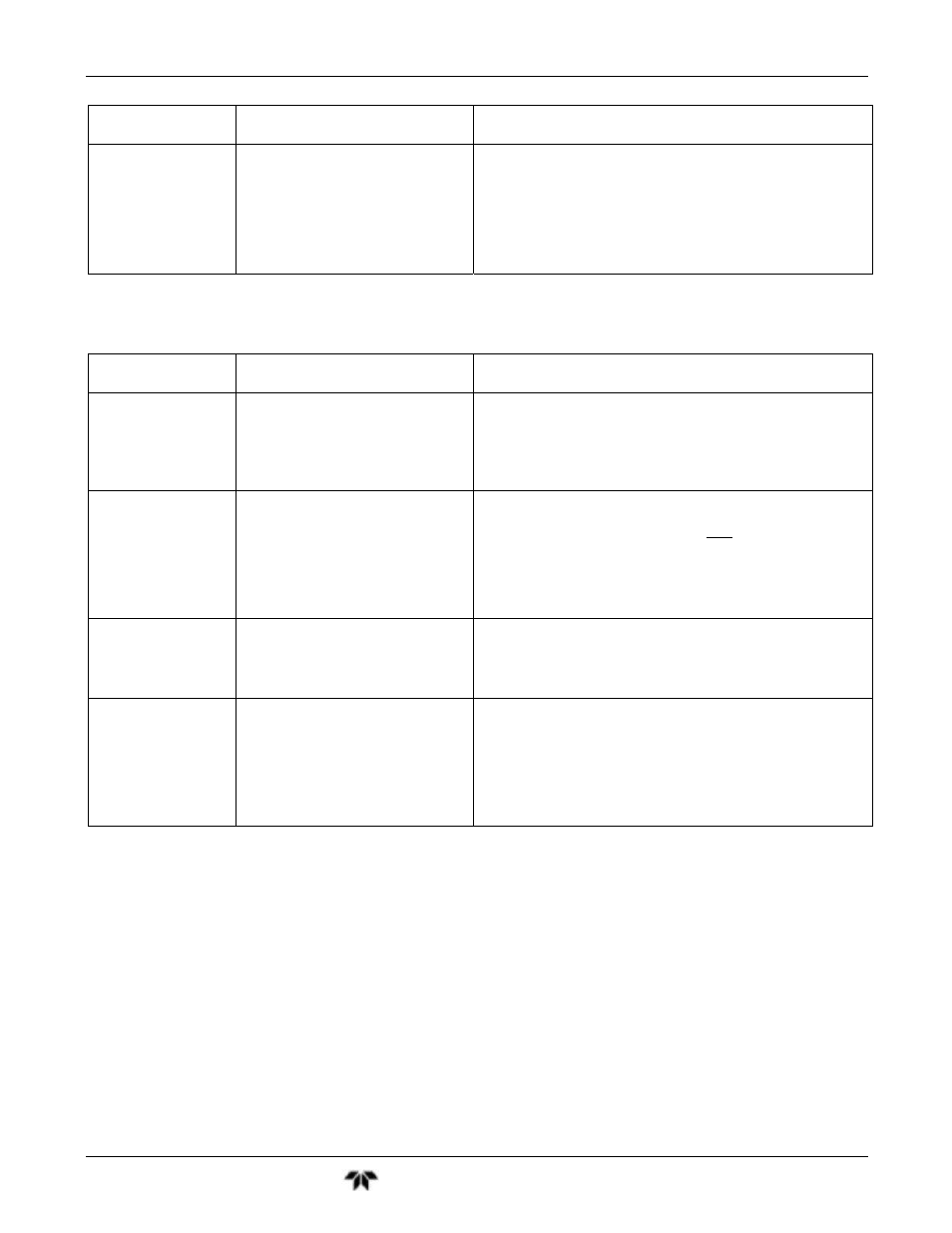

WARNING

MESSAGE

FAULT CONDITION

POSSIBLE CAUSES

SAMPLE PRES

WARN

Sample Pressure is <10 in-Hg or

> 35 in-Hg

Normally 29.92 in-Hg at sea level

decreasing at 1 in-Hg per 1000 ft of

altitude.

If sample pressure is < 10 in-hg:

Blocked particulate filter

Blocked sample inlet/gas line

Failed pressure sensor/circuitry

If sample pressure is > 35 in-hg:

Pressurized sample gas. Install vent

Blocked vent line on pressurized sample/zero/span gas supply

Bad pressure sensor/circuitry

Table 13-1: Warning Messages – Indicated Failures (cont.)

WARNING

MESSAGE

FAULT CONDITION

POSSIBLE CAUSES

SAMPLE TEMP

WARN

Sample temperature is < 10

o

C or >

100

o

C.

Ambient temperature outside of specified range

Failed bench heater

Failed bench temperature sensor

Relay controlling the bench heater

Failed relay board

I

2

C bus

SOURCE WARNING

Occurs when CO Ref is <1250

mVDC or >4950 mVDC.

Either of these conditions will result

in an invalid M/R ratio.

GFC Wheel stopped

Failed sync/demod board

If status LEDs on the sync/demod board ARE flashing the cause is

most likely a failed:

IR source

Relay board

I

2

C bus

IR photo-detector

SYSTEM RESET

The computer has rebooted.

This message occurs at power on. If you have not cycled the power

on your instrument:

Failed +5 VDC power,

Fatal error caused software to restart

Loose connector/wiring

WHEEL TEMP

WARNING

The filter wheel temperature is

controlled at 68

2

°

C

Blocked cooling vents below GFC Assembly. Make sure that

adequate clear space beneath the analyzer.

Analyzer’s top cover removed

Wheel heater

Wheel temperature sensor

Relay controlling the wheel heater

Entire relay board

I

2

C bus

12.1.2. FAULT DIAGNOSIS WITH TEST FUNCTIONS

Besides being useful as predictive diagnostic tools, the test functions viewable from the

front panel can be used to isolate and identify many operational problems when

combined with a thorough understanding of the analyzer’s Theory of Operation (see

Section 13).

The acceptable ranges for these test functions are listed in the “Nominal Range” column

of the analyzer Final Test and Validation Data Sheet (GFC7001T, P/N 04307 and

GFC7001TM, P/N 04311) shipped with the instrument. Values outside these acceptable

ranges indicate a failure of one or more of the analyzer’s subsystems. Functions whose