Pid control block parameters – Micromod MOD: 1800P - MOD 30ML Identity Module (Version 2) PID and Ramp/Soak Functions User Manual

Page 17

Continuous Control Functions

PID CONTROL BLOCK

2-11

Error Checks

If a calculation error occurs in the PID calculation, and the set qualities bad attribute is TRUE,

then the output qualities (output and track status) are set BAD. The PID calculation will be

initialized when qualities become good again.

In a cycle where the PID outputs have been previously marked BAD, but can now be

successfully calculated (required inputs are good), and the controller mode is AUTO or

CASCADE, the PID algorithm will initialize using the present output value. It is recommended

that the application design provide logic ’downstream’ of the PID block to set a track signal

when the PID qualities go bad. This way, the PID block will initialize from the track value

when it is again capable of executing, which would most likely be the preferred method of

initialization.

2.2.2

PID Control Block Parameters

The mnemonics, valid values, and data types for all fields that may be selected for display

and/or be used in making softwiring connections are listed in Table 2-1. The following further

defines the PID Control block configuration parameters.

Block Type

PID

This is the PID Control block type and is configured on the Function

Block Selection page.

Occurrence

1 to 4096

There may be up to 4096 ‘instances’ allowed of the PID block type.

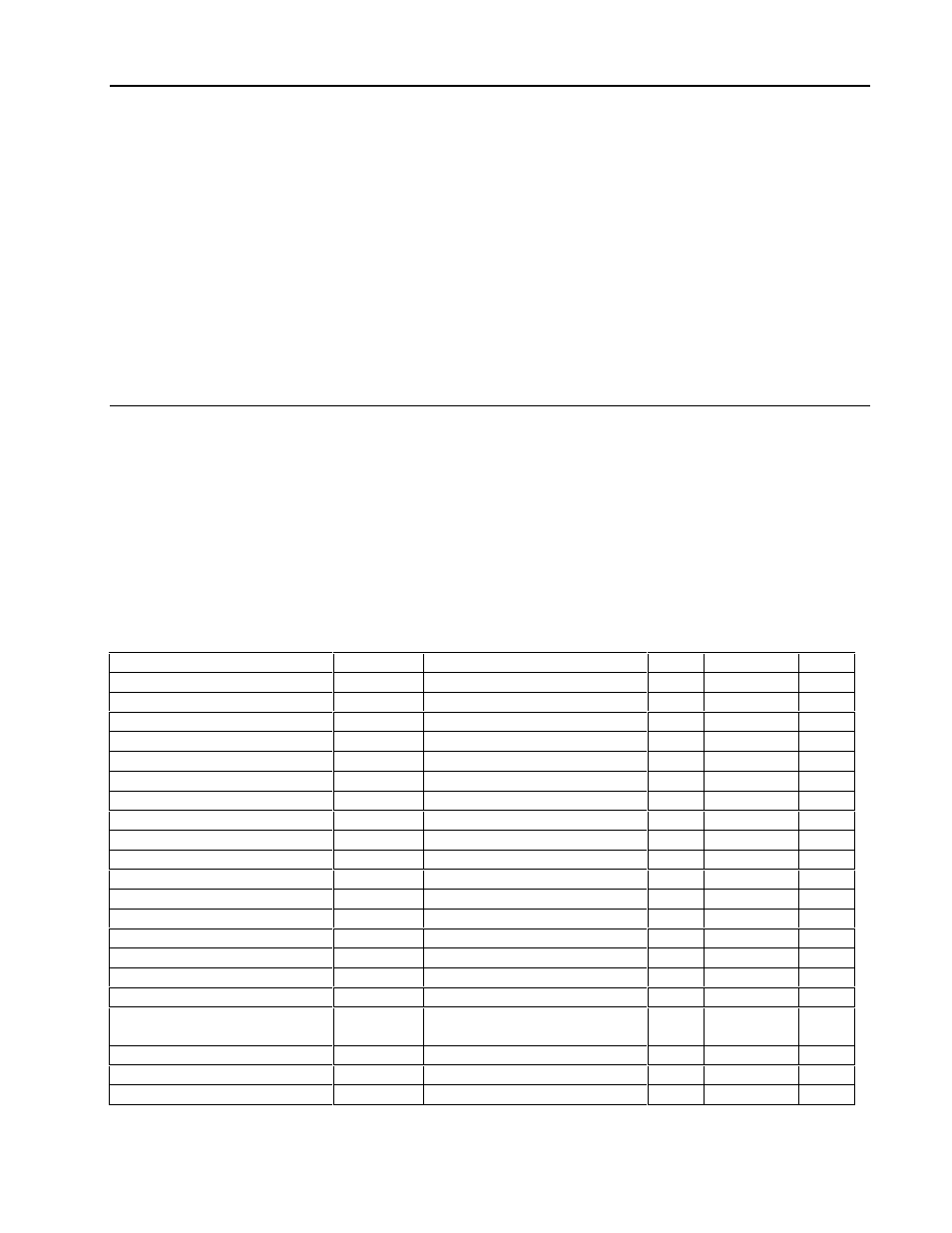

Table 2-1. PID Control Block Attributes, Valid Values, Mnemonics, and Data Types

Field Name /

Attribute

Mnemonic

Valid Values

CWR

Data Type

Attr

Version

VERSION

1

– – R Long State

00

Block Length

BLKLEN

– – R Count

01

Block State

STATE

RUN, HOLD, OFF, DEBUG

CWR Short State

02

Bad Inputs Accepted

BADINP

NO(0), YES(1)

CWR Discrete

03

Diagnostic Group

SUPPGRP

NONE, 1, 2, 3, 4, 5, 6, 7

CWR Long State

04

Calculation Error

CERRS

ENABLE(0), SUPPRESS(1)

CWR Discrete

05

Calc. Error Unacked

CERRU

NO(0), YES(1)

– WR Discrete

06

Calc. Error Unacked Quality

CERRUQ

GOOD(0), BAD(1)

– WR Discrete

07

Calc. Error Active

CERRA

NO(0), YES(1)

– WR Discrete

08

Calc. Error Active Quality

CERRAQ

GOOD(0), BAD(1)

– WR Discrete

09

Output Calculation Error

OPCERRS ENABLE(0), SUPPRESS(1)

CWR Discrete

10

Output Calc. Error Unacked

OPCERRU NO(0), YES(1)

– WR Discrete

11

Output Calc. Error Unacked Q

OPCERRUQ

GOOD(0), BAD(1)

– WR Discrete

12

Output Calc. Error Active

OPCERRA NO(0), YES(1)

– WR Discrete

13

Output Calc. Error Active Q

OPCERRAQ

GOOD(0), BAD(1)

– WR Discrete

14

Control Interval

CI

Msec Time Value

CWR Msec Time

15

Setpoint Modes Allowed

SPMA

L(1), R(2), L.R(3)

C – R Count

16

Setpoint Mode Status,

Initial Value

SPMS

LOCAL(0), REMOTE(1),

TRACK(3)*, FAULT(5)*

CWR Short State

17

Setpoint Mode Status Quality

SPMSQ

GOOD(0), BAD(1)

– WR Discrete

18

Setpoint Mode Command

SPMC

LOCAL(0), REMOTE(1)

– – R Short State

19

Setpoint Track Enable

SPTE

NO(0), YES(1)

C – R Discrete

20