Calibration setup, Preparing for calibration – Liquid Controls LCR 600 Setup & Op User Manual

Page 27

27

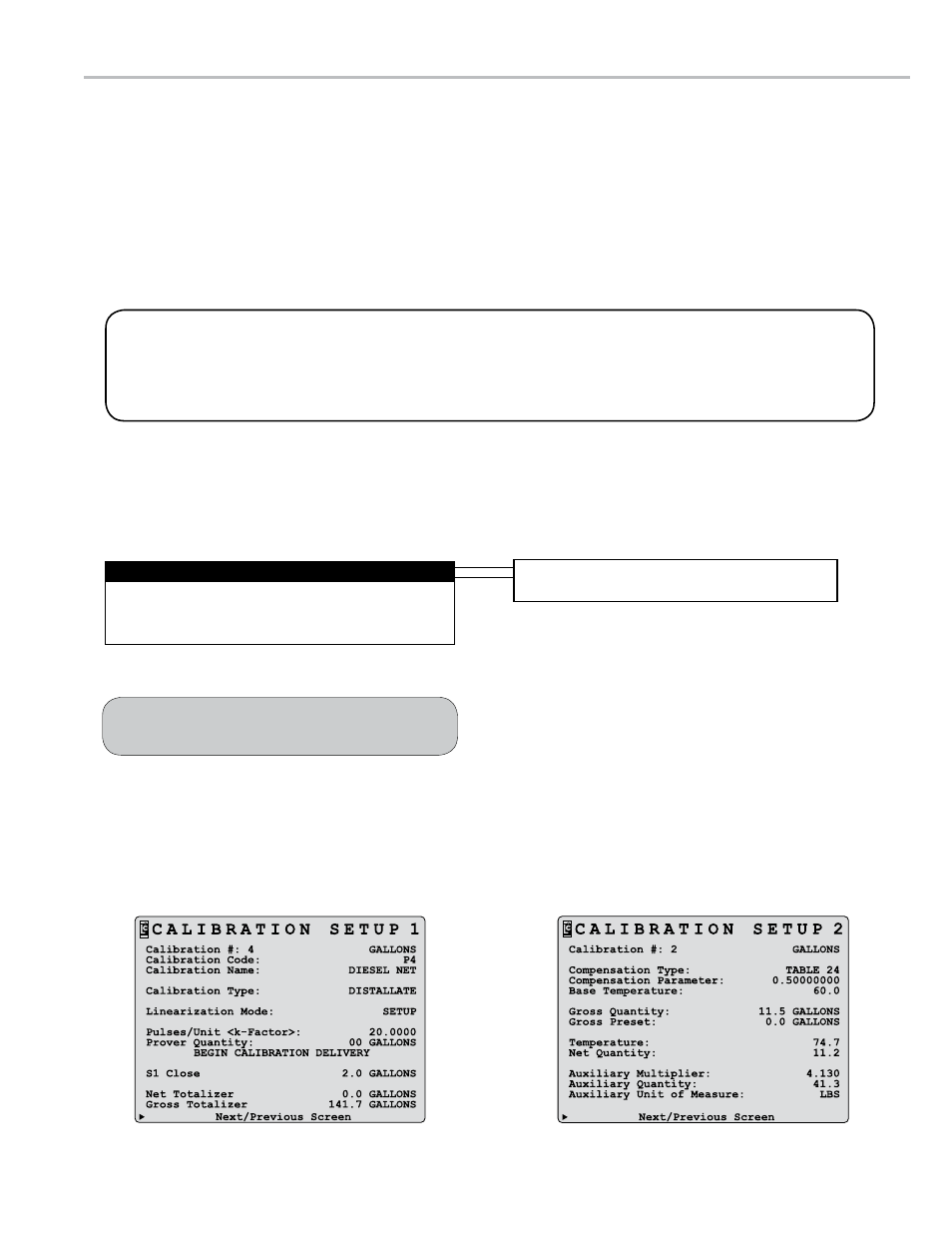

calIbratIon Setup

preparing for calibration

Before the LCR 600 is put into daily operation, the liquid(s) meant to be measured must be defined and proved. The

Calibration Setup screens provide the means to do so. The LCR 600 can hold a total of 16 different calibrations.

Calibrations must be defined according to type, and they can be named and coded for easy recognition. If the meter

system is equipped with electronic temperature volume compensation, Weights & Measures temperature calibration

can be made on Calibration Setup screen 2. The Calibration Setup screens also provide a field to set the dwell flow

(S1 Close:) and to calculate a second volume in an additional unit of measurement (Auxiliary Multiplier:

and Auxiliary Unit of Measure:). To prove the meter, you will use one of the BeGIN CALIBRATION

deLIVeRY

fields and the Pulses/Unit

The

Unit of Measurement:

field is on the

System Setup 1 screen .

calIbratIon and product termInology

Previous LectroCount models used the terms Product Code, Product Name, and Product Type for calibration purposes.

The LCR 600 has redefined these terms for the POS application and replaced them in the calibration setup with Calibration

Code

, Calibration Name, and Calibration Type

. The definition of “product” has expanded to include not only calibration

characteristics but also pricing and tax information.

Calibration #

’s can be overwritten and reproved.

Don’t accidentally overwrite a

Calibration #

currently in use.

Be Careful

to setup a calibration for a product (before

proving):

1. Remove the switchplate and move the selector switch to

the calibration position.

2. Navigate to the Calibration Setup 1 screen.

3. Choose a calibration number (1-16) from the

Calibration #:

field.

4. Define the calibration #. Enter the Calibration Code,

Calibration Name,

and Calibration Type.

5. Navigate to the Calibration Setup 2 screen.

6. If using electronic temperature volume compensation,

enter the correct Compensation Type. The

Compensation Parameter

and the Base

Temperature

fields will default to the values listed in

the table on page 28. Ensure these values are correct for

your application. Change them when necessary.

7. Make sure the hose is packed. See instructions on page

29.

8. You are now ready to prove the meter system.