Datamax-O'Neil Performance series User Guide User Manual

Page 130

7 | Troubleshooting

Performance Series User’s Guide

158

Note:

Some imperfections can be caused by a contaminated printhead. Clean the

printhead and reprint the label.

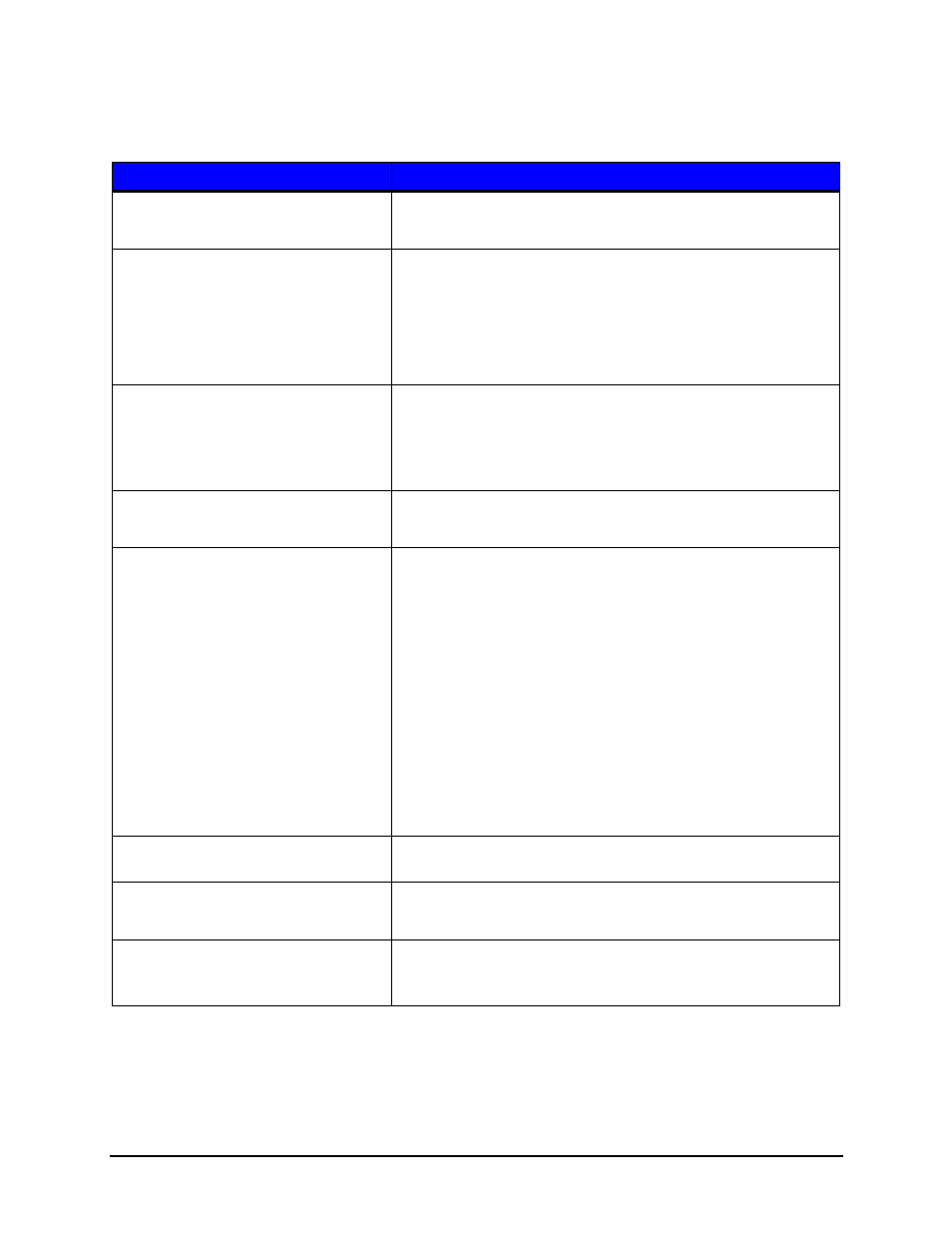

Symptom

Possible Solutions

No Print or Poor Print Quality

Verify the proper media and ribbon are being used.

Verify the printhead connections are fully seated.

Light Print on One Side

Adjust the ribbon cam and ribbon shield to add tension to the

light print side.

Verify the printhead connections are fully seated.

Replace the printhead.

Contact your technical support representative.

Print Quality Defect

Clean the printhead and platen roller with factory-approved

cleaning supplies.

Verify there are no ribbon folds or wrinkles under the printhead.

Replace the printhead if there is a missing dot.

Print Quality gets worse over time

Printhead is at the end of life and should be replaced.

Contact your technical support representative.

Diminished print quality on the Quality

Label

Incomplete horizontal lines requires an increase in the

sharpness setting and/or more tension applied to the lighter

print side of the ribbon shield.

For higher-grade barcodes, lighten the print by reducing the

darkness setting.

For white specks inside dark boxes, increase the darkness

setting and clean the printhead and platen roller.

If the small font is not readable, increase the darkness setting.

When dithering increments are not equal, adjust the darkness

setting.

If graphics are not displayed properly, adjust the sharpness

setting.

Ladder barcode quality is diminished

Examine the media adjustment levers and ensure there is a

.8mm to 1.5mm gap between the levers and the media.

Loud popping noise when printing

Increase darkness and sharpness settings.

Increase the front tension from the ribbon shield

Image size is out of the print area (off

the side or top or truncated from the

next label

Turn off print truncation.

Ensure the image width is the same as the print width.