Franklin Fueling Systems TS 550 evo Fuel Management System Programming Guide User Manual

Page 29

29

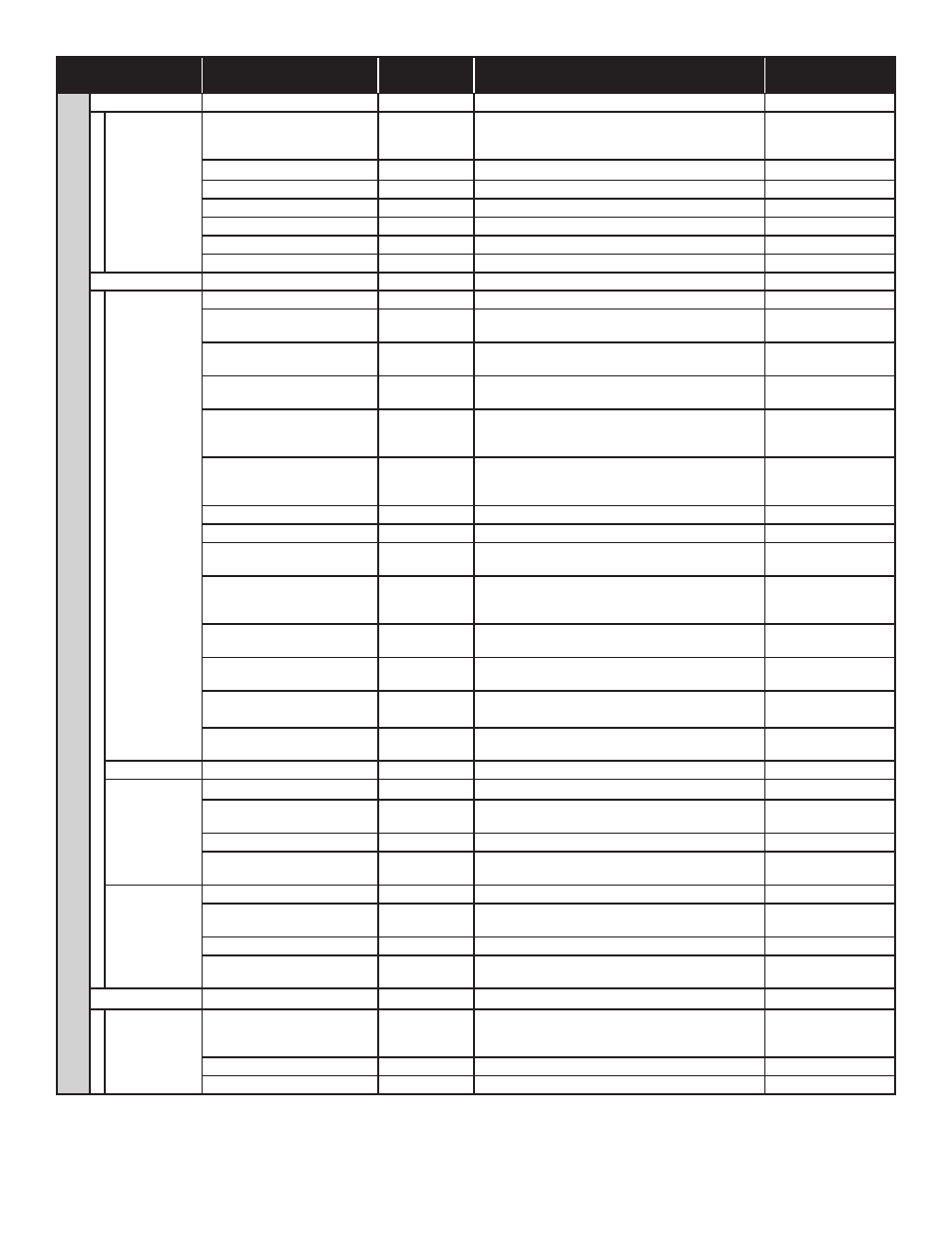

Group Name

Parameter Name

Parameter

Default

Description

Parameter Input

Special Products

Special N

Correction Type

(Table 6A)

As defined by the fuel provider

Table 6a

Table 6b

Table 6c

API Gravity

(63-500)

As defined by the fuel provider

#

Alpha

(600.000)

As defined by the fuel provider

#

Density

(500.0)

As defined by the fuel provider

#

Mole Weight

(130.000)

As defined by the fuel provider

#

Vapor A

(12.101)

As defined by the fuel provider

#

Vapor B

(8,907.000)

As defined by the fuel provider

#

Lines

Number of lines

(1)

Number of tanks in the fuel system

0-48

Line#

Name

(Line 1)

Given name of line

abc#

Submersible Pump module

(Relay Module) The module where the STP is connected

Relay Module

Power Supply Module

TPI

(Yes)

This option will appear if you select the Power

Supply Module

Yes / No

Submersible Pump Channel

(Relay 1)

Select the Relay Channel or pump that is

associated with this line.

Relays

Pumps

Transducer

(4-20mA Input

1)

Select the correct transducer for this line

UNL Transducer

Premium Transducer

Diesel Transducer

Enable SLLD

(Yes)

Select yes to enable Statistical Line Leak

Detection software. This will disable the scheduling

for Monthly Line Leak below

Yes / No

Product

(None)

Select the Product associated with this line.

Product N

Enable

(No)

Select Yes to enable line leak detection.

Yes / No

Monthly Compliance

(Yes)

Select Yes if this Line is to appear on the

Compliance page and in the Regulatory report.

Yes / No

Annual Compliance

(Yes)

Select Yes if this Line is to appear on the

Compliance page and in the Regulatory report for

annual tank testing.

Yes / No

Pressure Up Test Wait Time

(4 sec)

The amount of time to wait for Pressure to develop

in the line after demand has been made

1-8 sec

Catch Pressure Wait Time

(2 sec)

The amount of time to wait for the pressure in the

line to stabilize after dispensing has finished

1-4 sec

Dispenser Pressure Test

(Yes)

Select Yes if dispenser Pressure Test should be

performed.

Yes / No

Catch and Sudden Pressure

Test

(Yes)

Select Yes if Catch and Sudden Pressure Tests

should be performed.

Yes / No

Gross Test

Enable

(Yes)

Select Yes to Enable Gross leak test of 3 gph.

Yes / No

Monthly Tests

Enable

(Yes)

Select Yes to Enable monthly leak tests of 0.2 gph.

Yes / No

Wait Period Between Passed

Tests

(0 Days)

The amount of time the system will wait after a

passed monthly test before starting another one.

0, 1, 7, 14

Shutdown on Test Fail

(Yes)

Select Yes to disable dispensing upon a failed test.

Yes / No

Fails Before Shutdown

(1)

The number of fails before the system will disable

dispensing.

1-3

Annual Tests

Enable

(Yes)

Select Yes to Enable Annual leak tests of 0.1 gph.

Yes / No

Wait Period Between Passed

Tests

(0 Days)

The amount of time the system will wait after a

passed annual test before starting another one.

0, 7, 30, 90

Shutdown on Test Fail

(Yes)

Select Yes to disable dispensing upon a failed test.

Yes / No

Fails Before Shutdown

(1)

The number of fails before the system will disable

dispensing.

1-3

Grades

Grade 1

First Tank

(Tank 1)

Select the tank that Grade 1 is associated to.

Dependent on how many tanks and the tank

names

abc

Second Tank

(None)

Select a second tank if this grade is blended

abc

Blending Ratio

(100.00%)

Select the amount of product from the first tank

#%