Franklin Fueling Systems T5 Tank Sentinel Programming Guide User Manual

Page 44

40

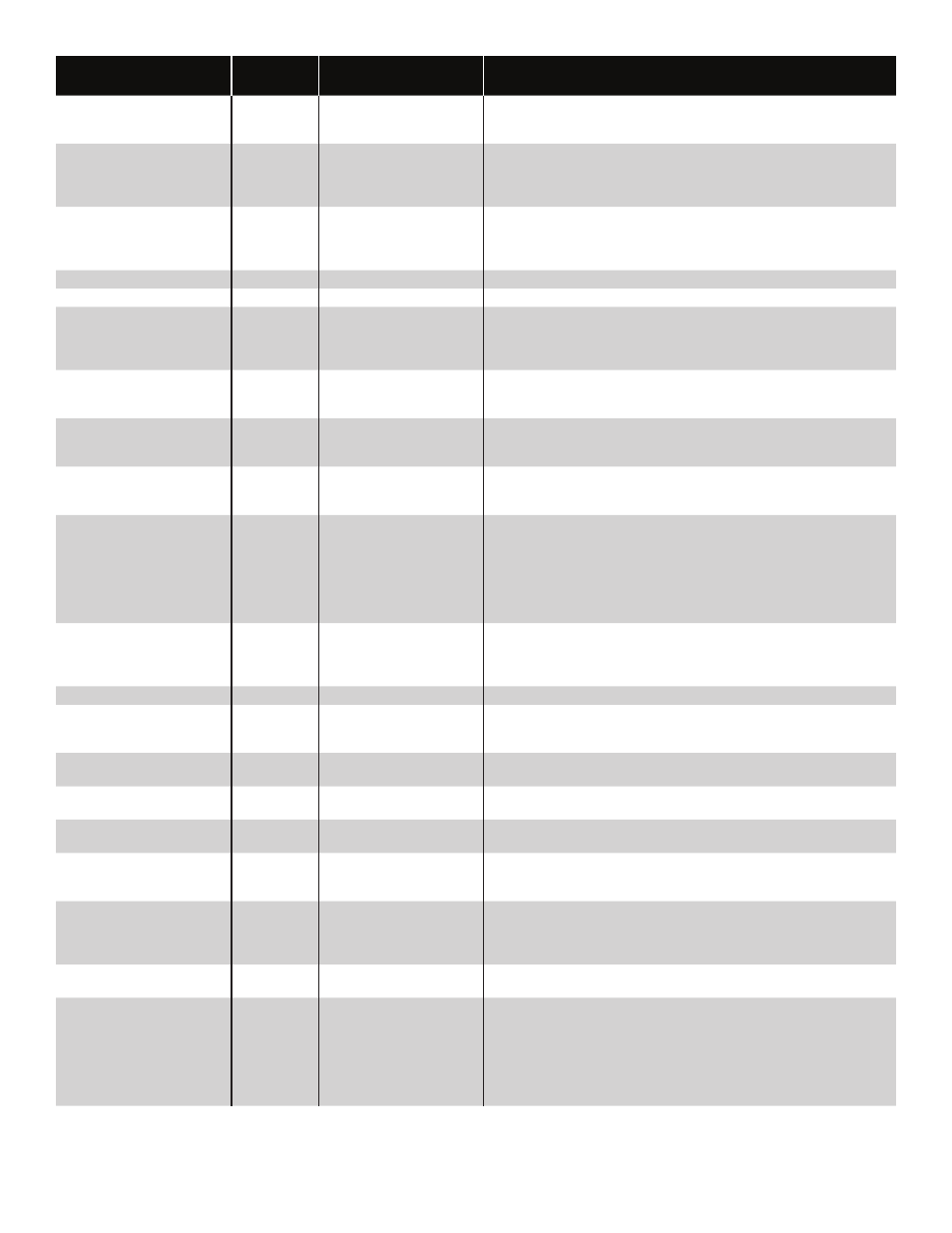

Displayed Alarm /

Warning

Device

Description

Recommended Actions

Probe Module Setup Error

None

Programming errors made

during setup of the Probe

Module.

Verify Probe Module programming parameters. If the condition still exists,

contact Franklin Fueling Systems’ Technical Services Dept. for support

on this issue.

Probe synchronization

error

Tank

Communications error

between probe and

console.

Only FFS Liquid Level LL2 Mag probes can be used with this system.

Verify probe programming. Check wiring continuity from probe to

console. If the condition still exists, contact Franklin Fueling Systems’

Technical Services Dept. for support on this issue.

Product volume error

Tank

Product net level exceeds

tank diameter due to

an error in console

programming.

Verify tank, offset, and probe programming.

Program Error Detected

Line

Engineering

Engineering

Pump Request Ignored

Line

Engineering

Engineering

Relay Module is Offline

Slot

Relay Module is offline due

to unknown causes.

Follow safety procedures before working inside the console. Visually

verify a steady green “Run” light. If red “Err” light is flashing or steady

try to reboot system. If the condition still exists, contact Franklin Fueling

Systems’ Technical Services Dept. for support on this issue.

Relay Module Setup Error

None

Programming errors made

during setup of the Relay

Output Module.

Verify Relay Output Module programming parameters. If the condition

still exists, contact Franklin Fueling Systems’ Technical Services Dept. for

support on this issue.

RTD table error

Tank

RTD distance error; Special

Probe programming error.

Verify correct RTD programming. If issue still exists, inspect wiring to

probe.If the condition still exists, contact Franklin Fueling Systems’

Technical Services Dept. for support on this issue.

SN2 Fuse Blown

Slot

2-Wire Sensor Module fuse

blown due to unknown

causes.

Follow safety precautions, refer to TS-5 Series FMS Installation Manual

for fuse replacement procedures.

SN2 Sensor On

ChannelSN2 Sensor shows alarm status. Visually inspect location carefully for pesence of liquid. In the case of

a leak, follow site policy procedures. If no liquid is present, and alarm

still exists, sensor may be tripped on error. Check wiring continuity from

sensor to console. Test sensor at console, trip sensor on purpose. Verify

console terminal wiring. If issue still exists, inspect wiring to probe.If

the condition still exists, contact Franklin Fueling Systems’ Technical

Services Dept. for support on this issue.

SN3 Data Error

ChannelSN3 Console has received

erroneous data from sensor.

Check wiring continuity from sensor to console. Test sensor at sonsole,

trip sensor on purpose. Verify console terminal wiring. If issue still exists,

inspect wiring to probe.If the condition still exists, contact Franklin

Fueling Systems’ Technical Services Dept. for support on this issue.

SN3 Dry Well

ChannelSN3 Monitoring well is dry.

Visually verify that the alarm is correct.

SN3 Fuse Blown

Slot

3-Wire Sensor Module fuse

blown due to unknown

causes.

Follow safety precautions, refer to TS-5 Series FMS Installation Manual

for fuse replacement procedures.

SN3 High Brine

ChannelSN3 Brine solution has tripped

high level brine sensor.

Verify actual level solution.

SN3 ID Error

ChannelSN3 Discriminating sensor is

given an improper ID.

Verify sensor programming and Auto configuration.

SN3 Low Brine

ChannelSN3 Brine solution has tripped

low level brine sensor.

Verify brine level.

SN3 No Signal

ChannelSN3 Console is not receiving

data signal from a

discriminating sensor.

SN3 Product

ChannelSN3 Discriminating sensor has

detected product present at

location.

Visually inspect location carefully for presence of liquid. In the case of

a leak, follow site policy procedures. If no liquid is present, and alarm

still exists, sensor may be tripped on error. Check wiring continuity from

sensor to console. Test sensor a

SN3 Pwr Short

Slot

3-Wire sensor malfunction.

Contact Franklin Fueling Systems’ Technical Services Dept. for support

on this issue.

SN3 Sensor On

ChannelSN3 Discriminating sensor

shows alarm status.

Visually inspect location carefully for presence of liquid. In the case of

a leak, follow site policy procedures. If no liquid is present, and alarm

still exists, sensor may be tripped on error. Check wiring continuity from

sensor to console. Test sensor at console, trip sensor on purpose. Verify

console terminal wiring. If issue still exists, inspect wiring to probe. If

the condition still exists, contact Franklin Fueling Systems’ Technical

Services Dept. for support on this issue.