Franklin Fueling Systems T5 Tank Sentinel Programming Guide User Manual

Page 42

38

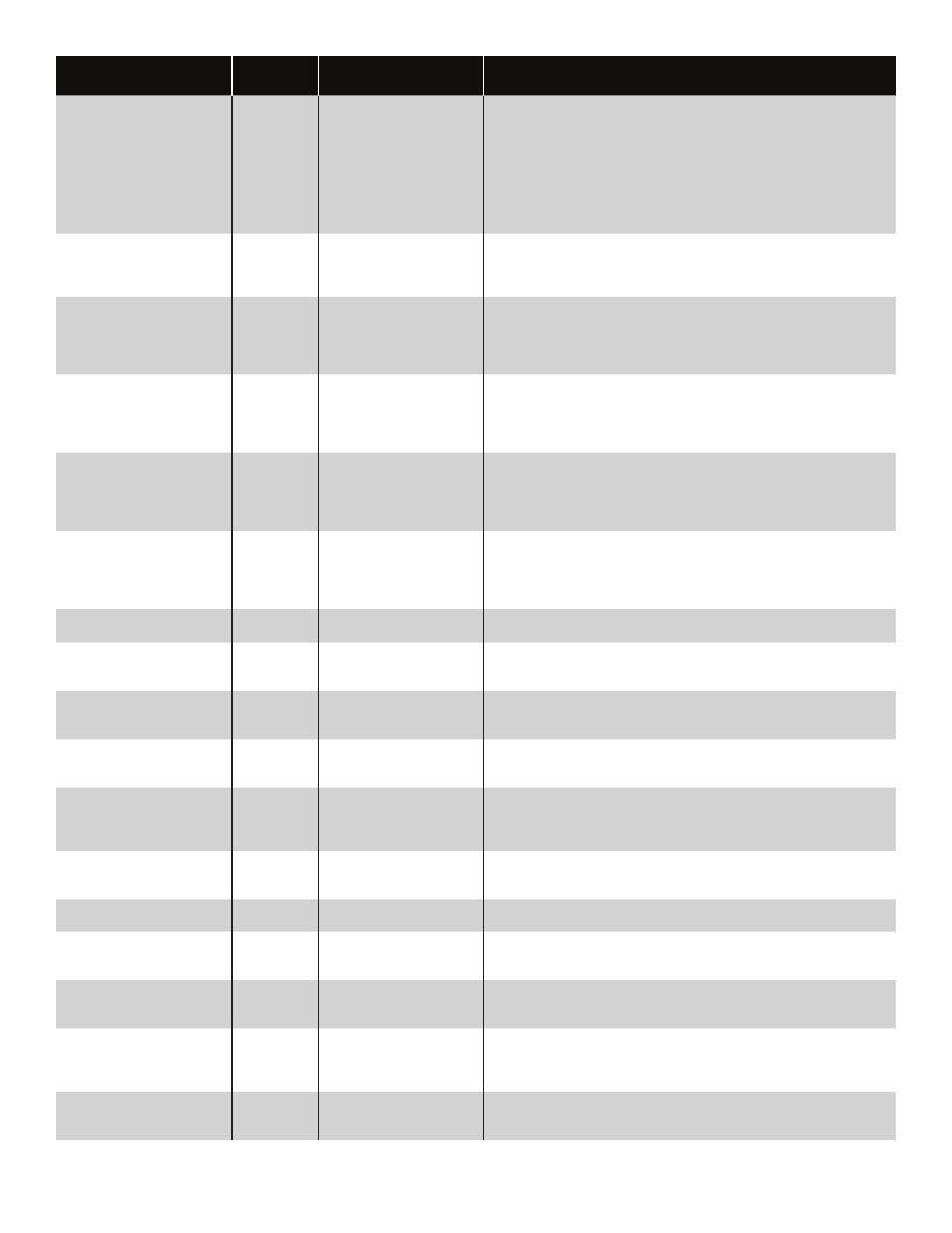

Displayed Alarm /

Warning

Device

Description

Recommended Actions

Dispensing Test Failed

Line

When pump is turned on,

a pressure test is started.

After specified time line

pressure must be at least

12 psi. Also, if test is

started manually an alarm

and shutdown will occur if

pressure during dispensing

drops to 7.5 psi or below.

Using a pressure gauge, test line pressure during dispensing. Observe

rise and fall of line pressure. If pressure is not at or above specified

pressure, per test, visually inspect all points for leaks of any proportion.

If unable to visually locate leak, or if pressures are correct and issue still

exists contact Franklin Fueling Systems’ Technical Services Dept. for

support on this issue.

Extended Hook Signal

Dispenser

Hook signal applied for an

extended period of time.

Following safety precautions for working with electrical circuits, check

wiring of hook signal to the console. Verify proper voltage is applied at

the when dispenser handle is lifted. If issue still exists contact Franklin

Fueling Systems’ Technical Services Dept. for support on this issue.

Failed to Catch Pressure

Line

AutoLearn Leak Sensing

Unit (LSU) did not detect

correct pressure threshold

within the time allotted after

pump turned off.

Verify Line programming. Observe multi-point line pressure readings

while pump is operating and when pump shuts off. If pressures meets

requirements specified, contact Franklin Fueling Systems’ Technical

Services Dept. for support on this issue.

Failed to Pressure Up

Line

AutoLearn Leak Sensing

Unit (LSU) did not detect

correct pressure threshold

within the time allotted after

pump turned on.

Verify Line programming. Observe multi-point line pressure readings

while comes on and when pump is operating. If pressures meets

requirements specified, contact Franklin Fueling Systems’ Technical

Services Dept. for support on this issue.

Float height error

Tank

This error could indicate

that the wrong float type

is installed or that a

programming error has

occurred.

Review probe programming for proper float type, number of floats, he

tank, this would be an idea time to clean the probe and floats.

Float Missing

Tank

Probe detects a lesser

number of floats than

programmed.

Review probe programming for correct number of floats. If correct then

inspect probe shaft, floats, and float magnets. With the probes out

of the tank, this would be an idea time to clean the probe and floats.

If pressures meets requirements specified, contact Franklin Fueling

Systems’ Technical Services Dept. for support on this issue.

FMS configuration error

None

Conflicts exist within FMS

Application programming.

Verify FMS setting are correct in accordance with the site specifications.

Fuel Management System

Setup Error

None

Programming errors made

during setup of the Fuel

Management System.

Verify FMS programming parameters. If the condition still exists, contact

Franklin Fueling Systems’ Technical Services Dept. for support on this

issue.

Gross Leak Detected

Line

Gross line leak test failed.

Inspect for leak, review tank leak test history and programming. Review,

why line tests fail (see …). It may be necessary to start a manual leak

test under the specified conditions.

High high product level

Tank

Product level exceeded

High High limit set. Possible

tank overfill condition.

Acquire an accurate product level. If actual product level in tank does

not match the consoles displayed current level, verify programming is

correct.

High product level

Tank

Product level exceeded

High limit set. Possible

close to tank overfill

condition

Acquire an accurate product level. If actual product level in tank does

not match the consoles displayed current level, verify programming is

correct.

High Pump Pressure

Line

Pump pressure exceeded

allowed limit.

Observe multi-point line pressure readings during pump on and off

conditions using a pressure gauge on the line. If line pressure high, there

may be a blockage in the line.

High water level

Tank

Water level exceeded High

limit set.

Verify programmed level. If water is too high consult you local site policy

procedures for corrective actions.

IS Barrier Violation

None

Non-Intrinsically Safe

module placed in IS area;

or IS Barrier is removed.

Follow safety procedures before working inside the console. Open

console to visually inspect module separation. If module is misplaced,

power down the console before working inside the unit.

Level error

Tank

Product level exceeds tank

diameter due to an error in

console of programming.

Verify tank, offset, and probe programming.

Line is not configured

Line

Specified line is not

configured, therefore

line leak test will not be

performed.

Verify line programming. If necessary configure line.

Line monitor disabled

Line

Specified line is not

enabled, therefore line leak

test will not be performed.

Verify line programming. If necessary enable line.