Franklin Fueling Systems T5 Tank Sentinel Programming Guide User Manual

Page 43

39

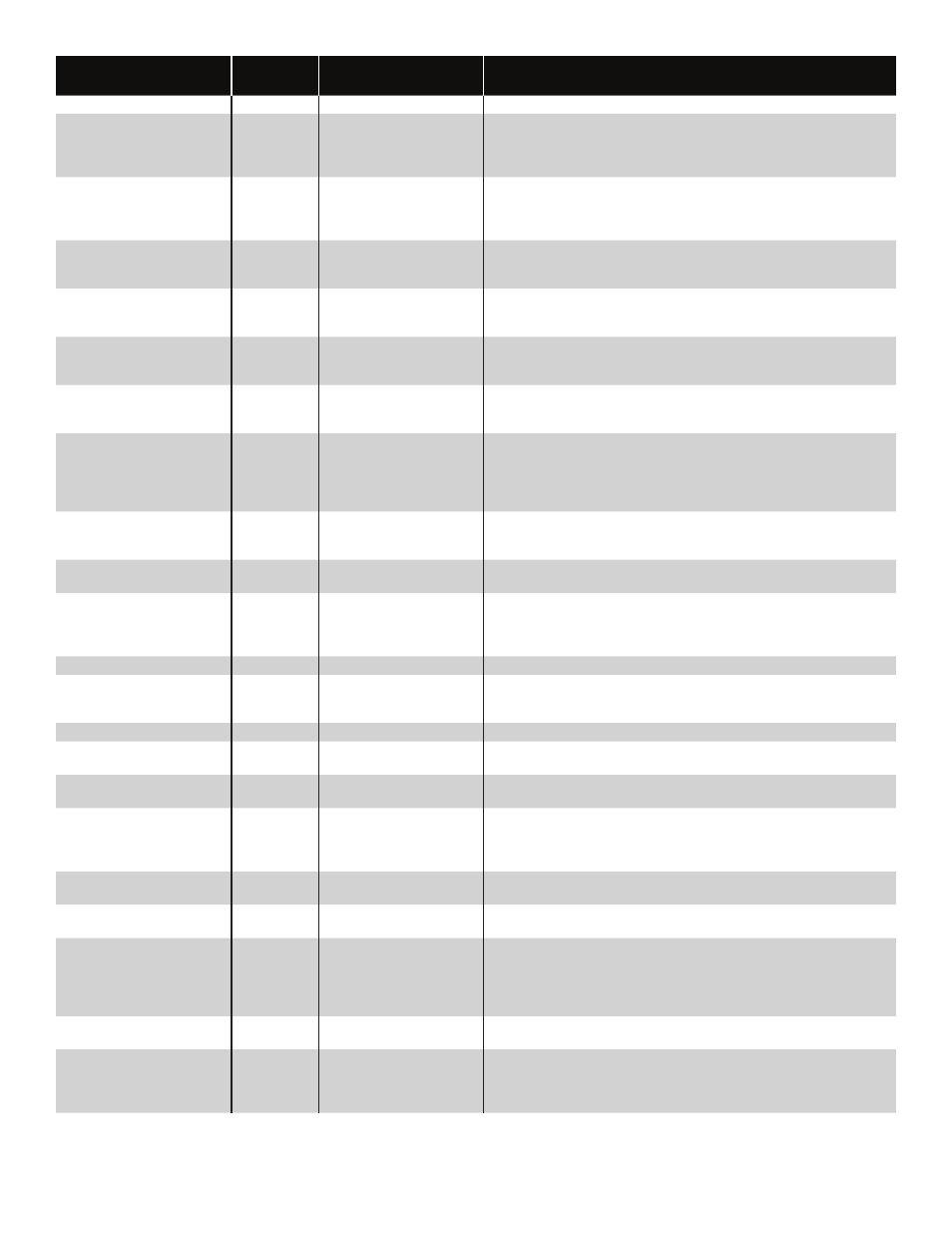

Displayed Alarm /

Warning

Device

Description

Recommended Actions

Low battery

Tank

Backup battery is low.

See Installation Guide for replacement instructions.

Low low product volume

Tank/Manifold Product volume below Low

Low limit set. The tank or

manifold specified may be

close to empty.

Acquire an accurate product volume. If actual product volume in

tank does not match the consoles displayed current volume, verify

programming.

Low product volume

Tank/Manifold Product volume below

Low limit set. The tank or

manifold specified may be

close to empty.

Acquire an accurate product volume. If actual product volume in

tank does not match the consoles displayed current volume, verify

programming.

Manifold Gross Leak

Detected

Manifold

A Gross leak is detected in

the specified manifold

Review tank leak test history and programming. Refer to Section

5: Misc./ Tank Leak Tests – Type and Frequency for instructions on

manually starting line leak tests.

Manifold Leak Detected

Manifold

A leak is detected in the

specified manifold

Review tank leak test history and programming. Refer to Section

5: Misc./ Tank Leak Tests – Type and Frequency for instructions on

manually starting line leak tests.

Manifold SCALD Leak

Detected

Manifold

SCALD software detected

a leak in the specified

manifold.

Review tank leak test history and programming. Review, why tank tests

fail.

Manifold Theft Detected

Manifold

Product used in Sentinel

Mode exceeds theft limit

set.

Verify theft limit in programming. Also obtain an accurate product level

and compare to inventory.

Marginal Pass of Gross

Leak Test

Line

Gross test passed with

marginal results. May

be caused by thermal

instability of the line or a

leak.

Engineering

Modem Error

None

Indicates that a modem

malfunction has occurred.

Try to recycle power on the console. Verify modem programming. If

the alarm does not clear, contact Franklin Fueling Systems’ Technical

Services Dept. for support on this issue.

Monthly Leak Test Failed

Line

0.2 GPH Line leak test

failed.

Follow site policy on line leak procedures.

Net error

Tank

Product net level exceeds

tank diameter due to

misconfiguration of

programming.

Verify tank, offset, and probe programming.

No data available

Tank

Engineering

Engineering

No probe detected

Tank

Communications error

between probe and

console.

Verify correct probe programming. If problem still exists, suspect wiring

or faulty probe head.

Not Enabled

Line

Specified line not enabled.

Verify programming.

Not Learned

Line

Specified line not learned.

Verify programming. If necessary to learn line see TS-5 Series FMS

Installation Manual for TS-Ls500 AutoLearn Calibration instructions.

Open analog input

Tank

No analog input signal.

Verify programming, if alarm is still present check wiring. If problem still

persists, suspect analog module to be at fault.

Power Supply Module is

Offline

Slot

Power Supply Module is

offline due to unknown

causes.

Follow safety procedures before working inside the console. Visually

verify a steady green “Run” light. If red “Err” light is flashing or steady

try to reboot system. If the condition still exists, contact Franklin Fueling

Systems’ Technical Services Dept. for support on this issue.

Power Supply Module

Setup Error

None

Errors in the setup of the

listed module.

The console may need to be reprogrammed.

Precision Leak Test Failed

Line

0.1 GPH Line leak test

failed.

Follow site policy on line leak procedures.

Pressure Transducer Fail

Line

Leak Sensing Unit

(Transducer) sending

erroneous data to console.

Only FFS AutoLearn TS-Ls500 Transducers can be used with this

system for line leak detection. Verify line leak programming. Check

wiring continuity from LSU to console. If the condition still exists, contact

Franklin Fueling Systems’ Technical Services Dept. for support on this

issue.

Printer Paper Jam

None

Indicates that paper is

jammed in printer.

Carefully lift printer cover to inspect and remove the jammed paper.

Probe Module is Offline

Slot

Probe Module is offline due

to unknown causes.

Follow safety procedures before working inside the console. Visually

verify a steady green “Run” light. If red “Err” light is flashing or steady

try to reboot system. If the condition still exists, contact Franklin Fueling

Systems’ Technical Services Dept. for support on this issue.