Maintenance schedule and maintenance intervals, Maintenance schedule and maintenance intervals -3 – Kodak RP 30 User Manual

Page 195

Maintenance

Maintenance Schedule and Maintenance Intervals

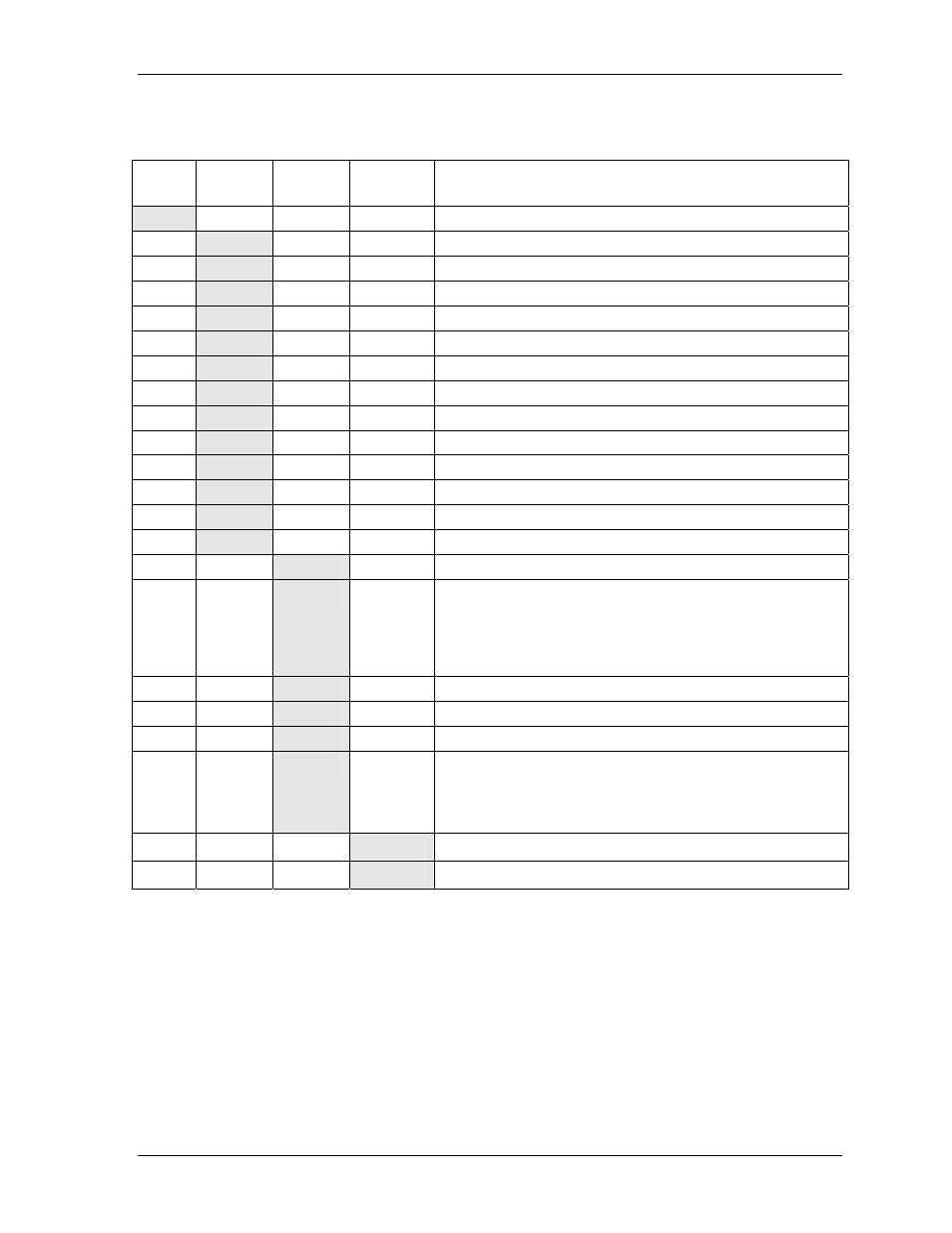

Daily Weekly Monthly When

required

Maintenance jobs to be performed by the customer

Perform process control on the paper processor

Transport unit: Remove paper dust

Single sheet buffer and sheet bridge: Remove paper dust

Print engine: Remove paper dust

Lane distributor: Remove paper dust / deposits

Sheet transfer to paper processor: Remove paper dust

Clean tank crossovers of the paper processor

Clean CD feed unit

Clean squeegee and wiper unit (V wipers)

Check solution levels, top up if necessary

Clean chemical filters

Clean filter in ASTOR and water inlets

Clean densitometer calibration plate

Print chute: Clean transport belt

Check solution temperatures

Clean air filters

– Below cutter units

– Door to print engine

– Paper processor: right-hand side wall, dryer and AC

supply

Replace the chemical filters

Clean processing racks

Clean dryer rack

Clean

paper

outlet:

– Clean / replace air filter

– Clean slide plate with feed chute

– Clean rubber transport belts

Change back printer ink ribbon

Empty effluent tanks

WARNING:

Be sure to observe the safety precautions on all equipment

labels and in the Regulatory and Safety section of this manual.

Do not clean while the drive is switched on.

To avoid risk of injury, be careful when working around the

toothed belts, sharp corners, and edges in the printer area.

KODAK PROFESSIONAL RP 30 Laser Printer

8-3