Siemens SIPART PS2 6DR52xx User Manual

Page 140

Operation

140

SIPART PS2 Manual

A5E00074631--06

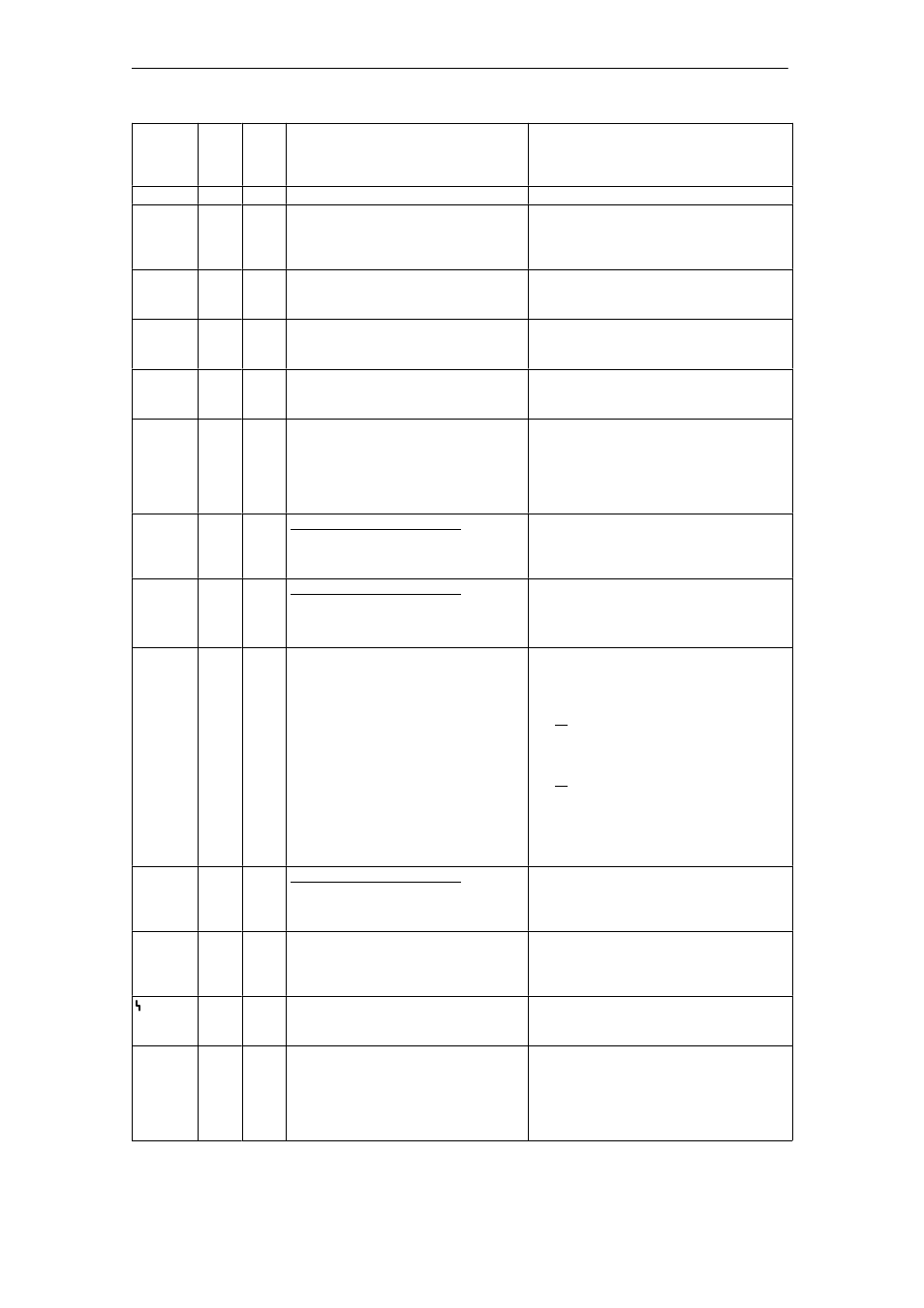

Messages during the installation phase:

Upper lin

e

Lower lin

e

Meaning/cause

Measure

P----

x

See above

See above

RUN 1

x

Initialization has been started, part 1

is active

(direction of action is being

determined)

S

Wait

RUN 2

x

Initialization, part 2 is active

(actuator travel check and

determination of the end stops)

S

Wait

RUN 3

x

Initialization, part 3 is active

(determination and display of the

actuating times)

S

Wait

RUN 4

x

Initialization, part 4 is active

(determination of the minimum

actuator increment length)

S

Wait

RUN 5

x

Initialization, part 5 is active

(optimization of the transient

response)

S

Wait until “FINSH” is displayed

(initialization completed successfully)

S

Press the operating mode button

briefly to acknowledge and exit the

configuration level by pressing it

continuously

YEND1

x

only for manual initialization

first end position can be approached

S

Approach first end position with the

“+” or “--” button

S

Press operating mode button to

acknowledge

YEND2

only for manual initialization

second end position can be

approached

S

Approach second end position with

the “+” or “--” button

S

Press operating mode button to

acknowledge

RANGE

x

only for manual initialization

End position or measuring span are

outside the permitted measuring

range

S

Press the “+” and “--” buttons to

approach another end position and

acknowledge with the operating

mode button,

or

S

adjust the friction clutch until “ok” is

displayed and acknowledge with the

operating mode button

or

S

cancel the initialization by pressing

the operating mode button, switch to

P manual mode and correct the

actuator travel and the position

displacement sensor

ok

only for manual initialization

permitted measuring range of the

end positions has been reached

S

Acknowledge with the operating

mode button, the remaining steps

(“RUN1” to “FINSH”) run

automatically

RUN 1/

ERROR

x

Error in RUN 1

no movement e.g. due to insufficient

compressed air

S

Make sure there is sufficient

compressed air

S

Open reactor(s)

S

Restart initialization

d___U

x

Bar graph display of the zero point

Zero point is outside the tolerance

range

S

Use friction clutch to set between

“P 4.0” and “P 9.9” ( >0< )

S

Continue with the “+” or “--” button

SEt

MIDDL

x

x

Friction clutch has been misadjusted;

no “P 50.0” display if the lever is in

horizontal position

S

With linear actuators, press the “+”

and ”--” buttons to move the lever at

right angles to the spindle

S

Press operating mode button briefly

to acknowledge (initialization is

continued)