5 diagnosis, 1 diagnostic display – Siemens SIPART PS2 6DR52xx User Manual

Page 122

Operation

122

SIPART PS2 Manual

A5E00074631--06

4.5 Diagnosis

4.5.1 Diagnostic display

To access the diagnostic display in automatic or manual mode,

press all three buttons for at least two seconds.

This following table gives an overview of the values that can be

displayed. The third column contains the term from which the

abbreviation is derived, unless it is self-explaining.

The structure of the diagnostic display is similar to that in “Configu-

ration” mode: the upper line shows the diagnosis value, the lower line

shows the number and abbreviation of the displayed value.

Use the operating mode button

to select the next diagnosis value.

By pressing and holding the operating mode button and simultaneously

pressing the decrement button

the diagnosis values can be

selected in reverse order.

Certain values can be set to zero by pressing the increment button

for at least 5 seconds. This is noted in the last table column.

Some diagnosis values can be greater than 99999. In this case, the

display switches to exponential indication. Example: the value for

1234567 is displayed as 1.23E6.

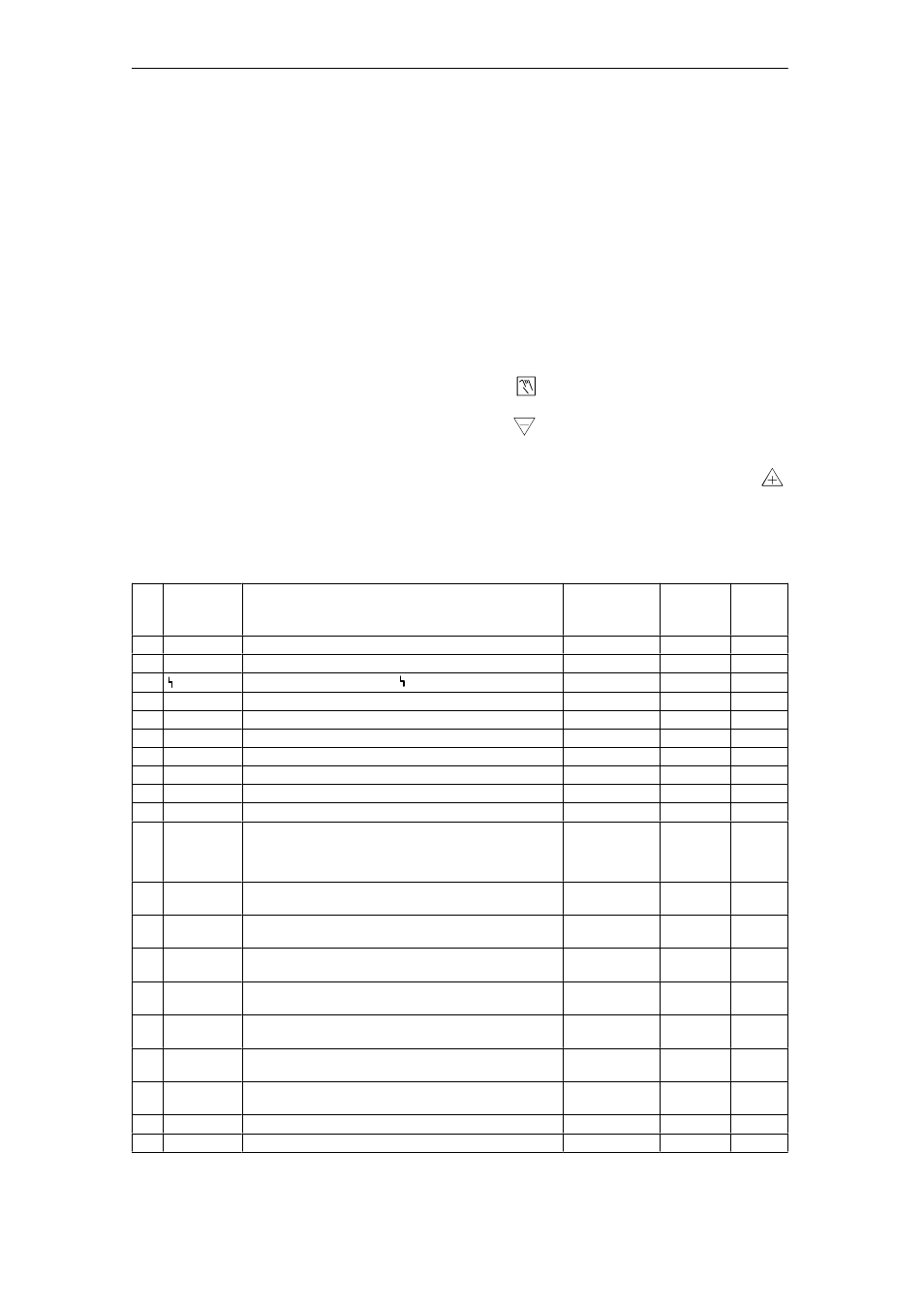

No. Abbre-

viation

Meaning

Values than

can be

indicated

Unit

Reset

possible

1

STRKS

Number of strokes (Strokes)

0 to 4.29E9

--

x

2

CHDIR

Changes of direction (Changes of Direction)

0 to 4.29E9

--

x

3

CNT

Number of fault messages ( Counter)

0 to 4.29E9

--

x

4

A1CNT

Number of alarms 1 (Alarm 1 Counter)

0 to 4.29E9

--

x

5

A2CNT

Number of alarms 2 (Alarm 2 Counter)

0 to 4.29E9

--

x

6

HOURS

Operating hours (Hours)

0 to 4.29E9

hours

7

WAY

Determined actuator travel (Way)

0 to 130

mm or _

8

TUP

Actuating time up (Travel Time Up)

0 to 1000

s

9

TDOWN

Actuating time down (Travel Time Down)

0 to 1000

s

10

LEAK

Leakage (Leakage)

P 0.0 to 100.0

%

11

PST

Monitoring of the Partial Stroke Test

OFF / ###.#,

fdini, notSt,

SdtSt, fdtSt,

notd, Strt

s for ###.#

12

PRPST

Time since the last Partial Stroke Test

###, notSt,

Sdtst, fdtSt

days

13

NXPST

Time until the next Partial Stroke Test

###, notSt,

SdtSt, fdtSt

days

14

DEVI

General control valve malfunction

Off, 0.0 to

100.0

%

15

ONLK

Pneumatic leakage

Off, 0.0 to

100.0

--

16

STIC

Slipstick effect

Off, --100.0 to

100.0

%

17

ZERO

Zero point offset

Off, --100.0 to

100.0

%

18

OPEN

Shifting the upper stop

Off, --100.0 to

100.0

%

19

PAVG

Average position value

0.0 to 100.0

%

20

P0

Potentiometer value lower stop (0%)

0.0 to 100.0

%