Siemens SIPART PS2 6DR52xx User Manual

Page 138

Operation

138

SIPART PS2 Manual

A5E00074631--06

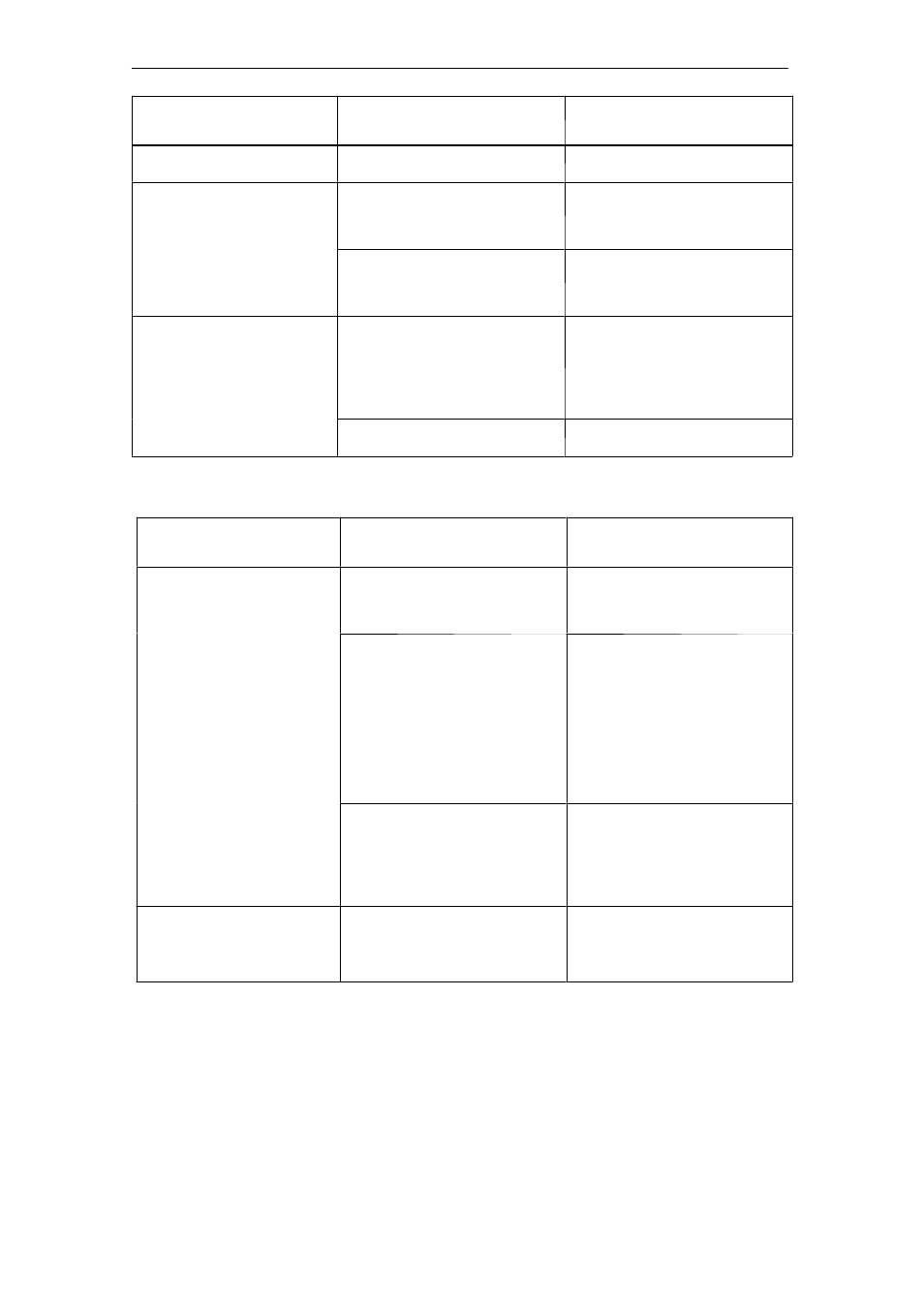

Fault indication

(symptoms)

possible cause(s)

Remedies

•

Actuator does not move

•

Compressed air < 1.4 bar

•

Set supply air pressure to

> 1.4 bar.

•

Piezo valve(s) do(es) not

switch (quiet “clicking” can

be heard however when

the + or – button is pressed

•

Reactor valve(s) closed

(screw(s) at the right-hand

stop)

•

Open reactor screw(s) (see

leaflet, figure “device view (6)”

by turning it/them

anti-clockwise.

the + or button is pressed

in manual mode).

•

Dirt in the pneumatic block

•

Repair (see chapter 5,

page 145) or new device;

integrated fine screen,

also replace and clean.

•

A piezo valve switches

continuously in stationary

automatic mode (constant

setpoint) and in manual

mode.

•

Pneumatic leakage in the

positioner – actuator system

Start leakage test in “RUN 3”

(initialization)!!!

•

Eliminate leakage in the

actuator and/or supply line

•

If the actuator is intact and the

supply line is leak-tight:

Repair (see chapter 5,

page 145) or new device

•

Dirt in the pneumatic block

(see above)

•

see above

Table 7

Fault indication

(symptoms)

possible cause(s)

Remedies

•

Both piezo valves switch

continuously and

alternately in stationary

automatic mode (constant

•

Too much slipstick of stuffing

box of control valve or actuator

•

Reduce slipstick or increase

dead zone of SIPART PS 2

(dEbA parameter) until

oscillation stops.

automatic mode (constant

setpoint) and in manual

mode, actuator oscillates

around a mean value.

•

Batches (play) in the positioner

-- actuator – control valve

system

•

Part--turn actuator:

Check if set screw of the

coupling wheel is inserted

firmly

•

Linear actuator:

Check if lever is connected

firmly to positioning shaft.

•

Eliminate any other play

between actuator and control

valve.

•

Actuator too fast

•

Increase actuating times via

reactor screws.

•

If fast actuating time is

required, increase dead zone

(dEBA parameter) until

oscillation stops.

•

SIPART PS 2 does not

“drive” control valve up to

the stop (at 20 mA).

•

Supply pressure too low.

•

Load of the feeding controller

or system output is too low.

•

Increase supply pressure

•

Interconnect load converter

•

Select 3/4 transmitter

operation

Table 8