Siemens SIPART PS2 6DR52xx User Manual

Page 132

Operation

132

SIPART PS2 Manual

A5E00074631--06

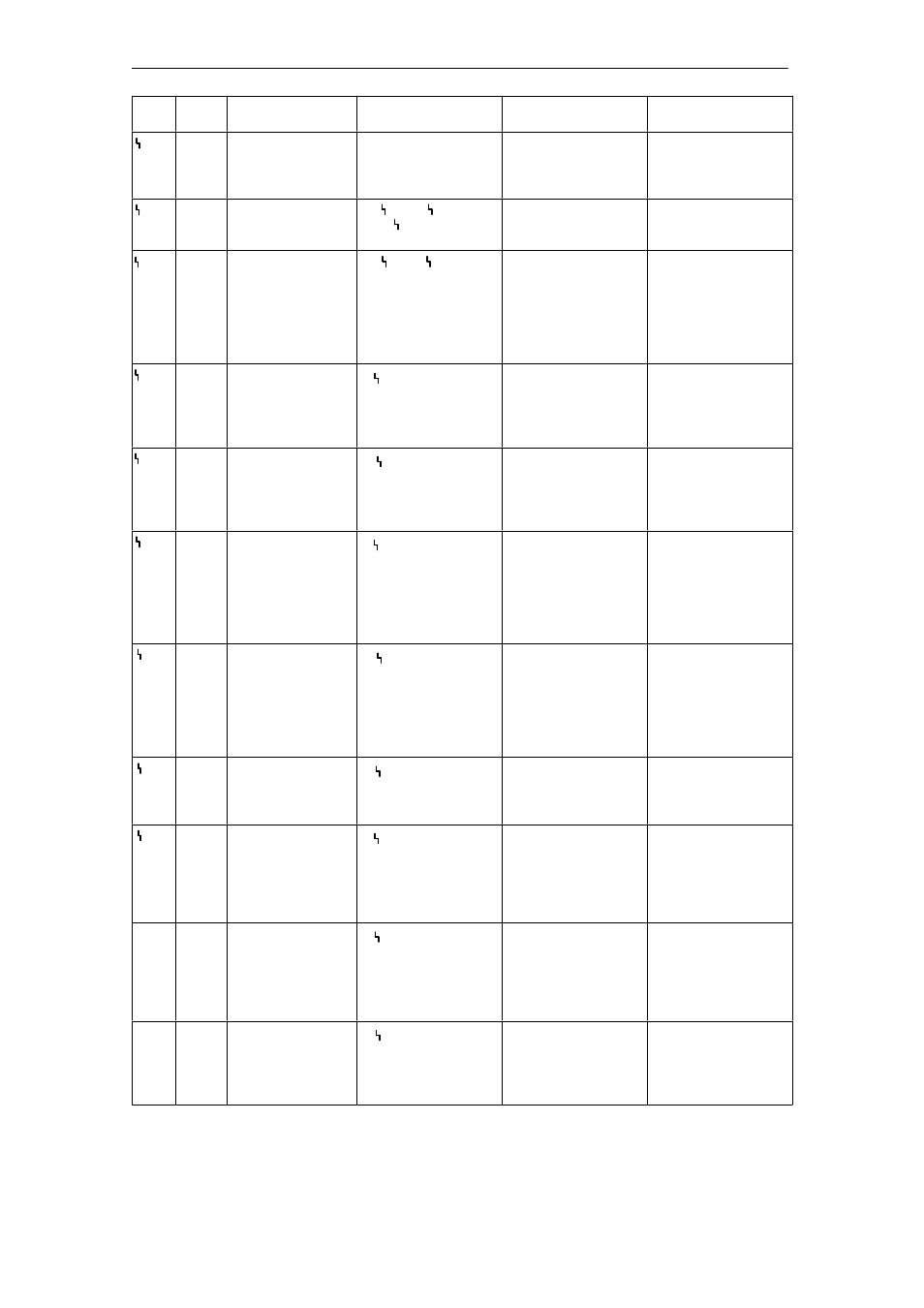

Error

code

three-

level

Event

Parameter-

setting

Error message

disappears if...

Possible

causes

1

no

Remaining control

deviation

always active

... the control

deviation has

disappeared again.

Compressed air

missing, actuator

fault, valve fault

(e.g. blockage).

2

no

Device not in

automatic mode

47. FCT= nA

or = nAB

... the device is

switched to automatic

mode.

The device is

configured or is in

manual mode.

3

no

Binary input BE1

or BE2 active

47. FCT= nAB

and binary function

BIN1 or BIN2 at “on”

... the binary input is

no longer activated.

The contact

connected to the

binary input became

active (e.g. stuffing

box monitoring,

overpressure,

temperature switch).

4

yes

Limit

Stroke number

exceeded

L. STRK¸OFF

... the stroke counter

is reset or the

thresholds are

increased

The sum of the

distance covered by

the actuator exceeds

one of the set

thresholds.

5

yes

Direction change

limit exceeded

O. DCHG¸OFF

... the direction

change counter is

reset or the

thresholds are

increased

The number of

changes of direction

exceeds one of the

set thresholds.

6

yes

Lower limit stop

limit exceeded

F. ZERO¸OFF

39.YCLS = do or up

do

... the deviation of the

stop disappears or

the device was

re-initialized.

Wear of the valve

seat, deposit or

foreign matter in

the valve seat,

mechanical

misadjustment, friction

clutch misadjusted.

7

yes

Limit

of upper limit stop

exceeded

G. OPEN¸OFF

39.YCLS = up or up

do

... the deviation of the

stop disappears or

the device was

re-initialized.

Wear of the valve

seat, deposit or

foreign matter in

the valve seat,

mechanical

misadjustment, friction

clutch misadjusted.

8

no

Limit

Dead zone

adaptation

exceeded

E. DEBA¸OFF

34.DEBA = Auto

... the value has

fallen below the limit

again.

Increased stuffing box

friction, mechanical

batches of the

position feedback.

9

yes

Partial stroke test

exceeds reference

step time

A. PST¸OFF

... a partial stroke test

is performed

successfully within

the reference step

time or the function is

deactivated.

Valve jams or is

rusted in place,

increased friction

10

yes

General control

valve malfunction

b. DEVI¸OFF

... the position is back

within a narrow

corridor between

guide value and

model, or the function

is deactivated.

actuator fault, valve

fault, valve jams,

increased friction,

compressed air drop

11

yes

Pneumatic leakage C. LEAK¸OFF

... the leakage falls

below the set

thresholds, or the

function is

deactivated.

Pneumatic leakage