Grizzly G0509 User Manual

Page 52

-50-

G0509 & G0509G 16" x 40" Lathe

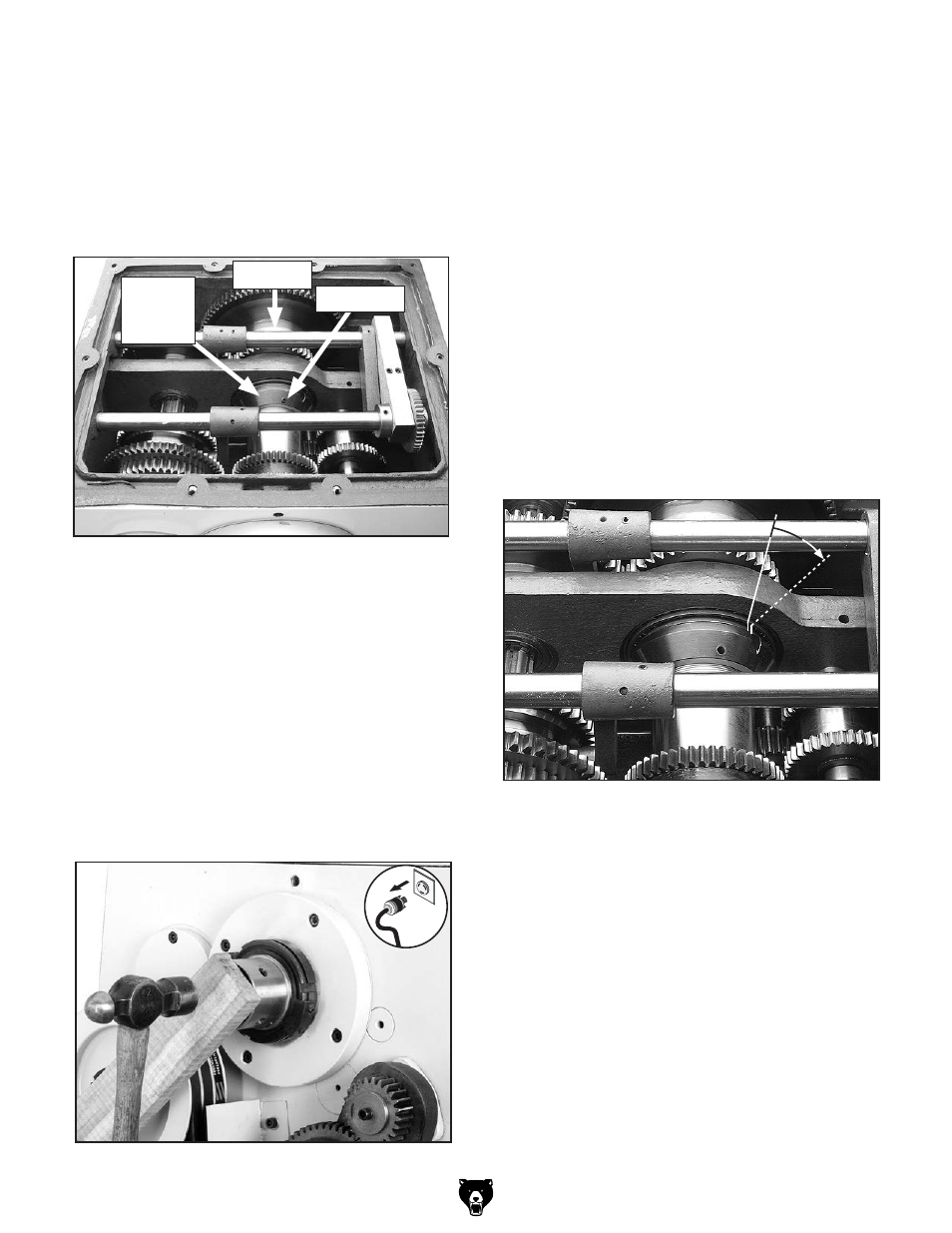

11. place the chuck key in the cam-lock socket

and keep the spindle from rotating.

12. using a spanner wrench, or hammer-and-

punch, loosen the preload spanner nut

(

figure 70) counterclockwise 1 turn.

13. place a wooden block over the outboard end

of the spindle, hit the block soundly with a

metal or heavy dead blow hammer (

figure

71). your goal is to slide the spindle forward

just enough to introduce spindle end-play that

you can feel by hand.

8. Move the carriage an additional 0.100" toward

the headstock.

9. using a 5mm hex wrench, remove the head-

stock lid to expose the headstock gears.

10. remove the preload spanner nut set screws

(

figure 70) with a 3mm hex wrench.

figure 70. preload spanner nut.

figure 71. introducing detectable end-play.

set screw

preload

spanner

nut

since it can take great effort to turn the pre-

load spanner nut, you may find it difficult to

know if you have gone past the zero end-

play point or not. you may find it easiest to

have someone watch the dial for you while

you tighten the inner spanner nut. if you think

you may have gone past the zero end-play

point, take the time to unload the bearings

as described earlier, then re-tighten the inner

spanner nut until you know you have reached

the correct setting.

When you are confident that you have adjust-

ed the preload spanner nut until zero spindle

end-play and but preload exists, you now

must move the spanner nut inward and addi-

tional 0.001" to set the preload.

14. to set the preload, rotate the spanner nut an

additional 0.16" as shown in

figure 72.

figure 72. preload spanner nut adjustment.

0.16"

15. reinstall the setscrews in the preload span-

ner nut.

16. position the gasket correctly, and re-install

the headstock cover.

17. tighten the outboard spindle spanner nut

until it is snug and reinstall the locking set-

screw.

18. reinstall the lathe end cover, and make sure

the counterweights (

figure 73) do not rub on

the cover when the lathe is turned on.

spindle