Grizzly G0509 User Manual

Page 23

G0509 & G0509G 16" x 40" Lathe

-21-

12. Move the spindle rotation ON/OFF lever

(

figure 9) down until the chuck begins to

turn. the top of the chuck should turn toward

you.

—if the chuck is rotating away from you, then

you must complete the

changing motor

rotation procedure on page 22, and

repeat the entire

test run procedure.

13. push the emergency stop button.

—if the lathe does not stop, move the spindle

rotation

ON/OFF lever to the central posi-

tion (

OFF), and disconnect the lathe from

power. refer to

troubleshooting on page

43 for correction.

14. return the spindle rotation ON/OFF lever to

the central position (

OFF), reset the emer-

gency stop button, and restart the lathe.

15. push the foot brake, and the lathe should

come to a quick stop.

—if the lathe does not stop, push the emer-

gency stop button, and disconnect the lathe

from power. refer to

troubleshooting on

page 43 for correction.

16. return the spindle rotation ON/OFF lever to

stop, restart the lathe, and let the lathe run

for a minimum of 10 minutes at 330 rpM in

both directions. do not lEAVE thE lAthE

running unAttEndEd!

17. After 10 minutes, stop the lathe, and move

the headstock speed levers to select the next

highest rpM. run the lathe in both directions

for 10 minutes.

18. repeat for the remaining rpM ranges pro-

gressively increasing in rpM. When these

steps are complete, the lathe is broken in.

19. drain and refill the lubricant in the headstock

with Mobil dtE

®

oil or an equivalent. refer

to

lubrication on page 40 for the procedure

and apron oil change interval.

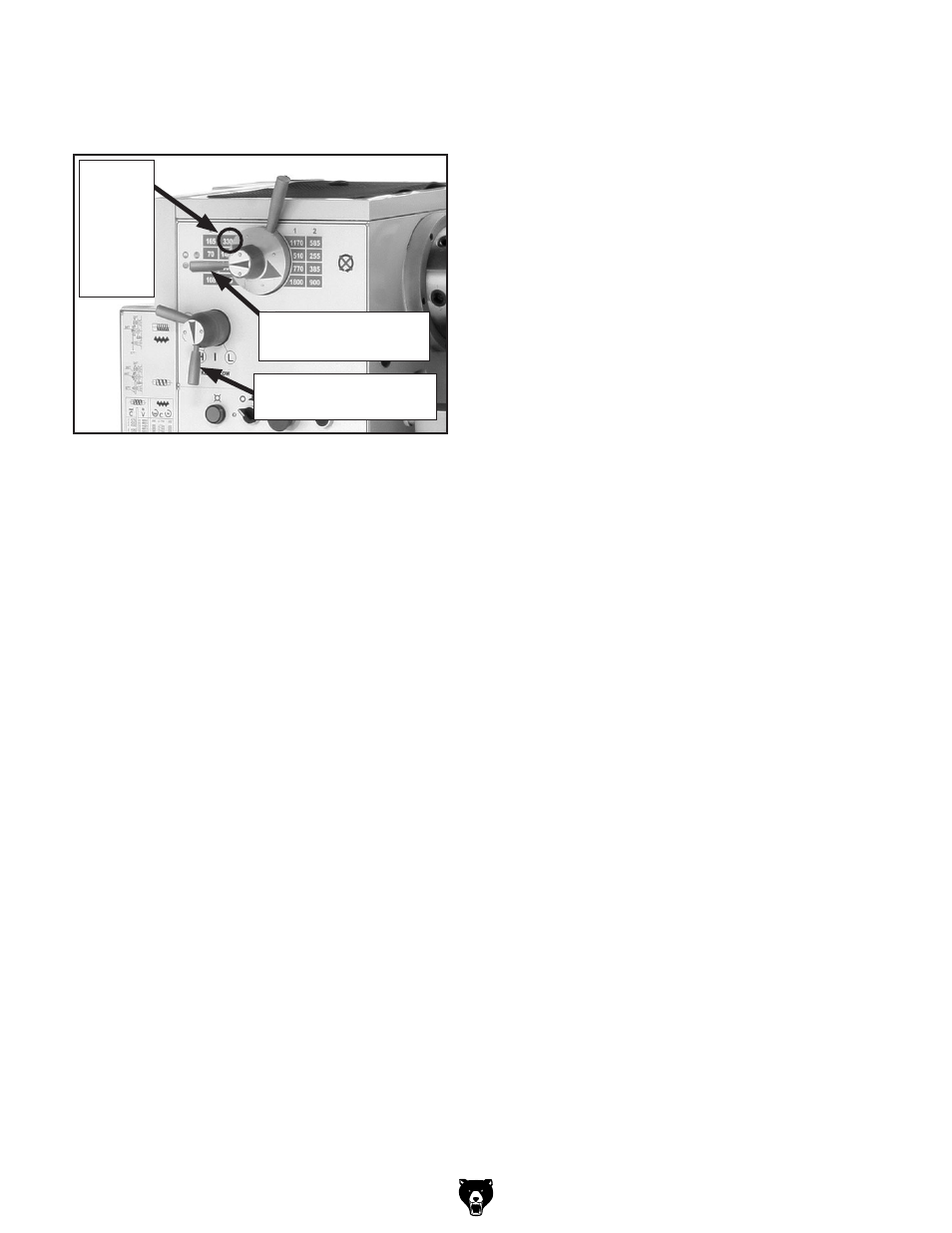

figure 11. headstock controls.

gearbox high/low

lever pointing down

330

rpM

selected

with the

speed

lever

speed range lever

is pointing to the left

11. Move the three headstock levers so they are

positioned as shown in

figure 11 so 330

rpM is selected.