Camlock stud adjustment, Notice – Grizzly G0509 User Manual

Page 39

G0509 & G0509G 16" x 40" Lathe

-37-

camlock stud

adjustment

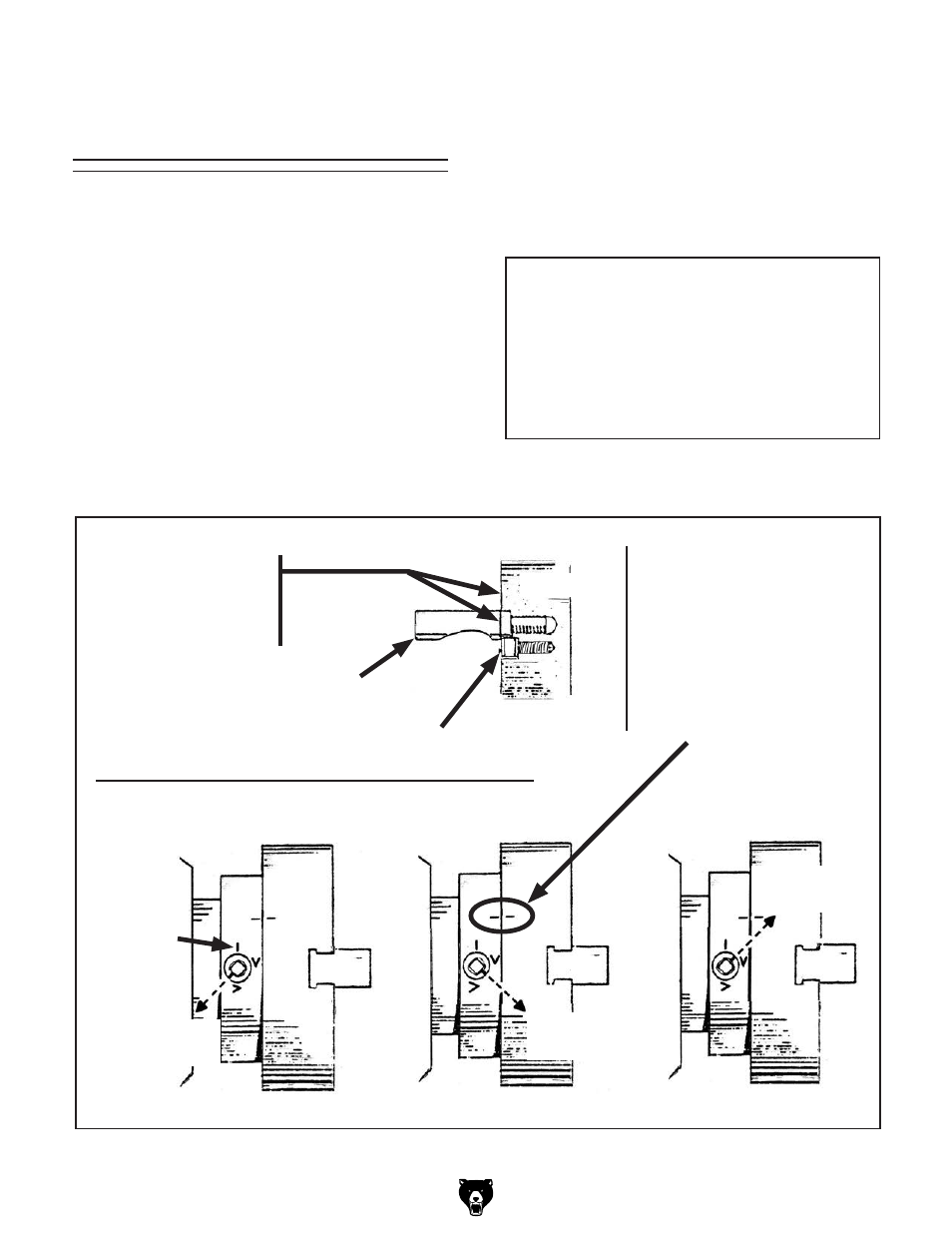

When fitting a chuck or faceplate with camlock

studs, or when mounting a new chuck or face-

plate, it may be necessary to adjust the camlock

studs.

in order to properly install or adjust one or more

camlock studs, you must remove a stud locking

cap screw, then thread the camlock stud in or out

until the line on the side of the stud is flush with

the top of the chuck casting (

figure 39). this is

an initial adjustment.

When you place the chuck onto the lathe spindle,

you may find that one or more camlocks do not

fully point between the "

v" marks on the chuck.

incorrect

correct

Between

Arrows

turn stud

in one turn

incorrect

turn stud out

one turn

Cam

release

datum

Camlock

stud

Camlock Cap screw is tight But Camlock

stud Can still rotate Back and Forth slightly

initial Adjustment:

Camlock stud

Alignment groove

is Flush with Chuck

surface

ChuCK

Chuck-to-spindle

timing Mark

figure 39. Camlock stud alignment.

if this is the case, you will have to remove the

chuck and fine-tune the camlock stud adjustment.

see

figure 39 for which direction to turn the

camlock studs.

once you have adjusted the camlock studs, install

the chuck or faceplate as outlined in

to install

chuck or faceplate on page 36.

NOTICE

never install a chuck or faceplate without

having the camlock cap screws in place

or fully tightened. if you ignore this notice,

the chuck may never be able to be removed

since the camlock studs will turn with the

camlocks and never release.