Feed rod and leadscrew gearbox ratio levers, Notice – Grizzly G0509 User Manual

Page 30

-28-

G0509 & G0509G 16" x 40" Lathe

feed rod and

leadscrew

gearbox ratio

levers

the leadscrew/feed rod lever (

figure 21) engag-

es and disengages the leadscrew and feed rod

simultaneously. When the lever is moved up or

down, the rotation of the leadscrew and feed rods

are simultaneously reversed.

the three-position gearbox high/low range lever

(

figure 21) will put the gearbox into high range

"

h", low range "l", or neutral "

I".

note: Make sure to loosen the carriage lock

(

Figure 28) when apron power feed or threading

are to be used. The carriage lock is used only to

increase carriage stability when facing operations

are in process.

NOTICE

only shift the gearbox levers when spindle

speed is less than 500 rpm and the gear-

box speed range lever is in neutral. never

force a lever. if the lever will not engage, use

the jog button when applicable so the teeth

mesh and the lever drops into position.

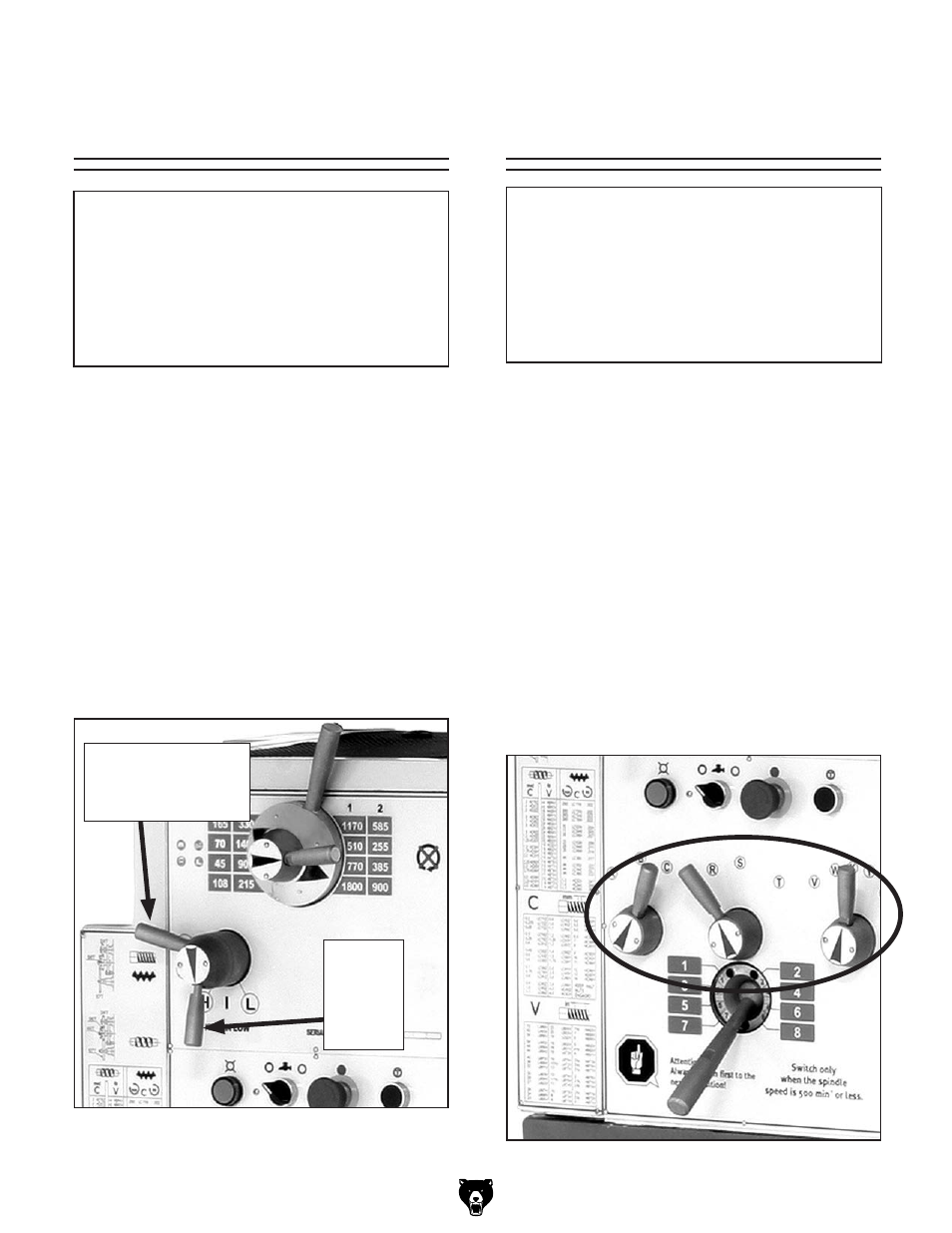

figure 21. gearbox input and output controls.

leadscrew/Feed

rod direction lever

(output)

gearbox

high/low

range

lever

(input)

figure 22. gearbox range levers.

NOTICE

only shift the gearbox levers when spindle

speed is less than 500 rpm and the gear-

box speed range lever is in neutral. never

force a lever. if the lever will not engage, use

the jog button when applicable so the teeth

mesh and the lever drops into position.

the gearbox has a series of levers used for con-

trolling the feed rod and leadscrew feed rates in

relationship with the spindle speed.

Based on the threading and feed rate chart, you

can shift the gearbox to accommodate an elabo-

rate array of feed rates. the three gearbox range

levers (

figure 22) have multiple lettered posi-

tions (

figure 24), and when moved according

to the threading chart and example on the next

page, you can quickly change the feed rate. the

example on the next page shows the lathe setup

to cut a

"3.5mm" thread using the "lcr8y" lever

combination.

note: The change gear must be in the position

shown in

Figure 23.