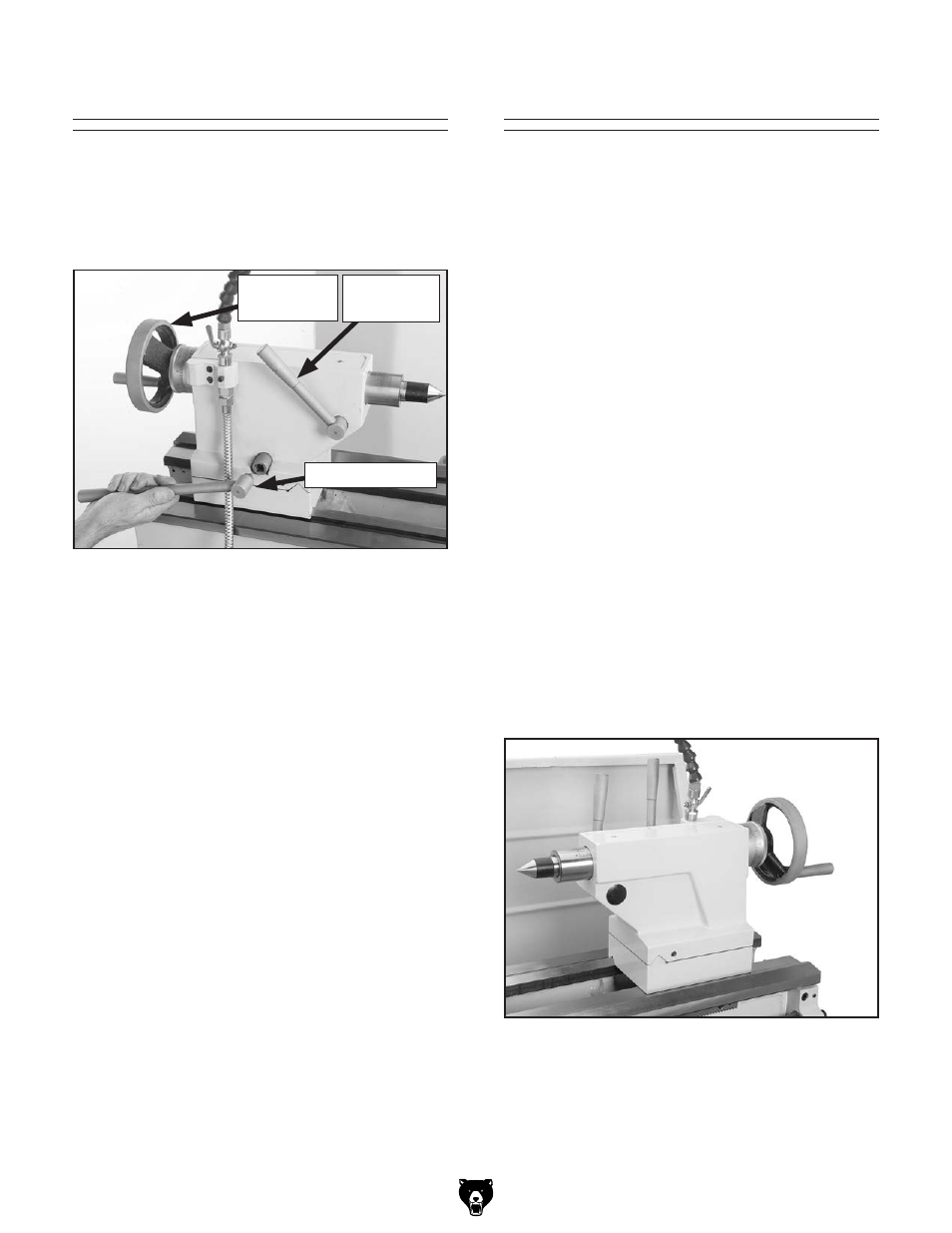

Centers, Tailstock controls, Tailstock handwheel – Grizzly G0509 User Manual

Page 35: Barrel lock lever, Side lock lever & torque tightening (g0509g)

G0509 & G0509G 16" x 40" Lathe

-33-

centers

A tailstock center supports stock that is too long

to be supported by the chuck alone. the tailstock

barrel and dead center have an Mt#4 taper.

included with this lathe is an Mt#4 to Mt#6 spin-

dle adapter sleeve. if you need to install a center

in the spindle when using the face plate, you can

do so by using this adapter sleeve.

Before installing a center or arbor, make sure that

the mating surfaces are perfectly clean. these

parts will last longer and remain accurate if prop-

erly maintained. if oil is present on the mating

surfaces, the tapers will not interlock.

to install the center, insert the end of it into the

tailstock bore until it seats. once the workpiece

is installed, the force of a mounted workpiece will

fully seat the taper.

When using a dead center (

figure 33), the

tailstock barrel should protrude about

1

⁄

2

" and not

more than 2

3

⁄

4

" as indicated by the scale on the

barrel.

to remove the dead center, back the tailstock

barrel all the way into the tailstock casting. the

dead center will pop out. Be sure to catch it when

it comes out to avoid damaging the tip.

figure 33. dead center installed in tailstock.

tailstock controls

the tailstock (

figure 32) serves many func-

tions. the primary use is holding centers and drill

chucks. the barrel has an Mt#4 (morse taper #4)

bore and is imprinted with graduations in millime-

ters and inches.

figure 32. tailstock controls.

tailstock handwheel

turning the handwheel advances or retracts the

barrel in the tailstock. the graduated dial on the

handwheel is adjustable.

barrel lock lever

this lever locks the tailstock barrel in place.

side lock lever & torque

tightening (g0509g)

this removable lever locks the tailstock in place

on the lathe bed. the socket that it fits into will

accept a

1

⁄

2

-inch drive torque wrench.

to repeat very accurate vertical alignment posi-

tioning, tighten the tailstock here with an inch-

pound torque wrench. if you must, you can use a

foot-pound torque wrench but do not exceed 40

lbs/ft of torque or you may damage the ways and

the tailstock. When tightening the tailstock down

to the maximum torque of 40 lbs/ft, the center

point will be drawn down approximately 0.006"

from the normal centerline when the tailstock is

resting free on the ways.

side lock lever

Barrel lock

lever

tailstock

handwheel