Bearing preload – Grizzly G0509 User Manual

Page 51

G0509 & G0509G 16" x 40" Lathe

-49-

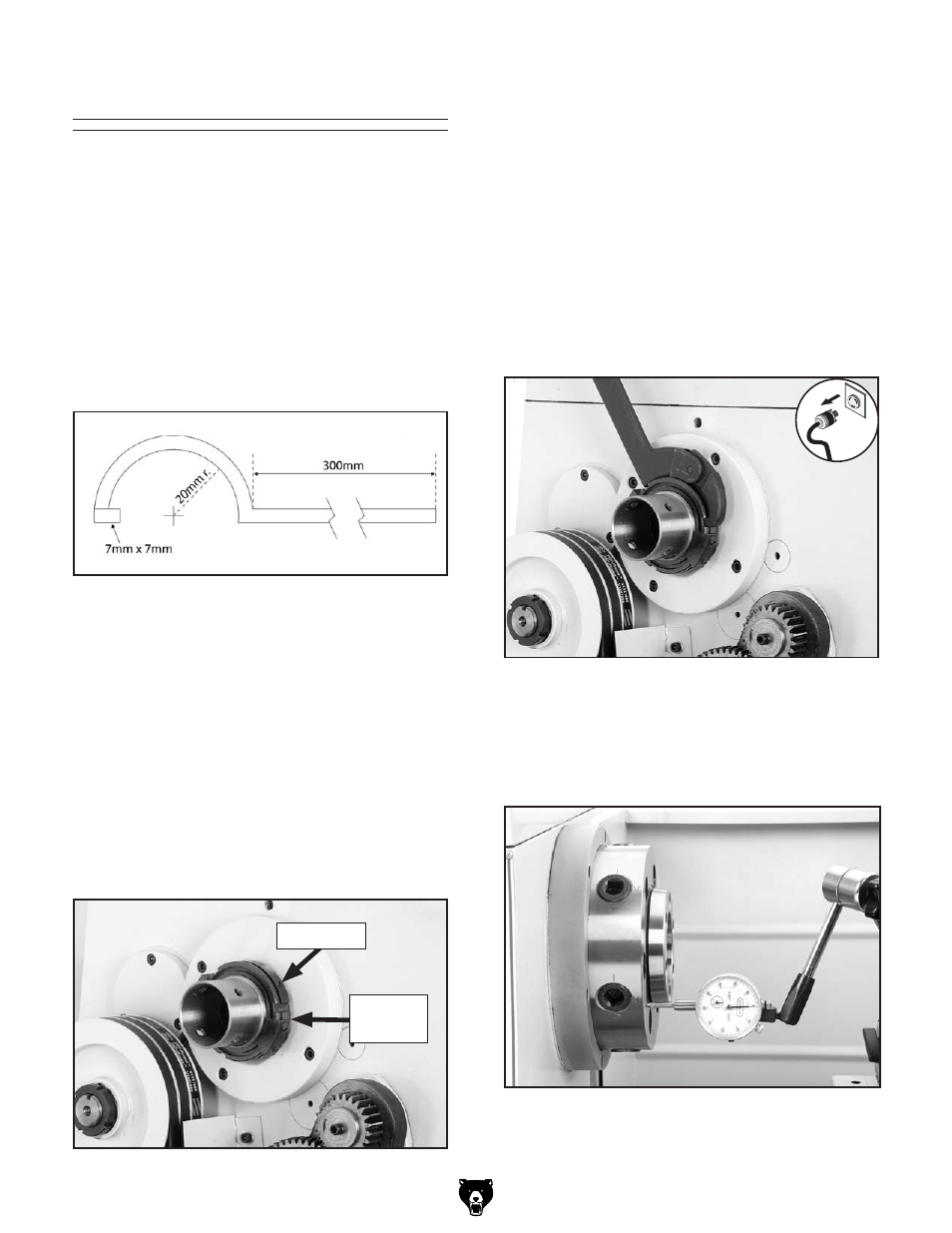

figure 66. spanner wrench diagram.

bearing preload

this lathe is shipped from the factory with the

spindle bearing preload adjusted. if the spindle

ever develops a bit of end-play and the workpiece

finish suffers, you can adjust the bearing pre-

load to remove the end-play and improve the

workpiece finish.

Adjusting the bearing preload requires using a

spanner wrench or a punch and hammer. you

can either purchase the spanner wrench at a tool

store or fabricate one, using the diagram shown

below in

figure 66.

to adjust the preload:

1. run the lathe for 20 minutes on high speed

to bring the lathe to normal operating

temperature.

2. disConnECt thE lAthE FroM thE

poWEr sourCE!

3. remove the chuck, shift the spindle to

neutral, then remove the lathe end cover to

expose the outboard spindle and spanner nut

(

figure 67).

figure 67. outboard spindle/spanner nut.

figure 68. loosening outboard spanner nut.

4. using a 3mm hex wrench, remove the spanner

nut locking set screw (

figure 67).

5. place the chuck key in the cam-lock socket to

keep the spindle from rotating.

6. using a spanner wrench, or hammer-and-

punch, loosen the spanner lock nut (

figure

68) counterclockwise three turns.

note: You may have to tap on the outboard

spindle tube as explained in

Step 13 to help

unload the spindle and break the spanner nut

loose.

figure 69. dial indicator setup.

7. place a dial indicator on the cross slide and

move the carriage toward the headstock until

the contact point of the indicator touches the

spindle face (

figure 69).

set screw

spanner

nut