Notice, Gap removal – Grizzly G0509 User Manual

Page 26

-24-

G0509 & G0509G 16" x 40" Lathe

8. loosen the tailstock lock lever and adjust the

tailstock offset by the amount of the taper

by turning the adjustment set screw (

figure

17). turn another 0.010'' off of the stock and

check for taper. repeat as necessary until

the desired amount of accuracy is achieved.

— if the stock is thinner at the tailstock end,

the tailstock needs to be moved away from

the operator by at least the amount of the

taper (

figure 16).

figure 16. Adjusting for tailstock end taper.

looking down from above.

figure 17. tailstock adjustment locations.

NOTICE

do not forget to lock the tailstock to the

ways after each adjustment.

Adjustment screw

gap removal

your lathe has a gap section below the spindle

that can be removed for turning large diameter

parts. this gap was installed, then ground at the

factory during lathe assembly for precise fit and

alignment. Factors during original lathe assem-

bly apply additional forces to the gap; therefore,

replacing the gap to the original position will be

very difficult.

We don't recommend removing

the gap. if removed for turning large diameter

parts, reinstallation to exact factory alignment

is nearly impossible. the only option is to

then leave the gap out and lose carriage travel

near the chuck.

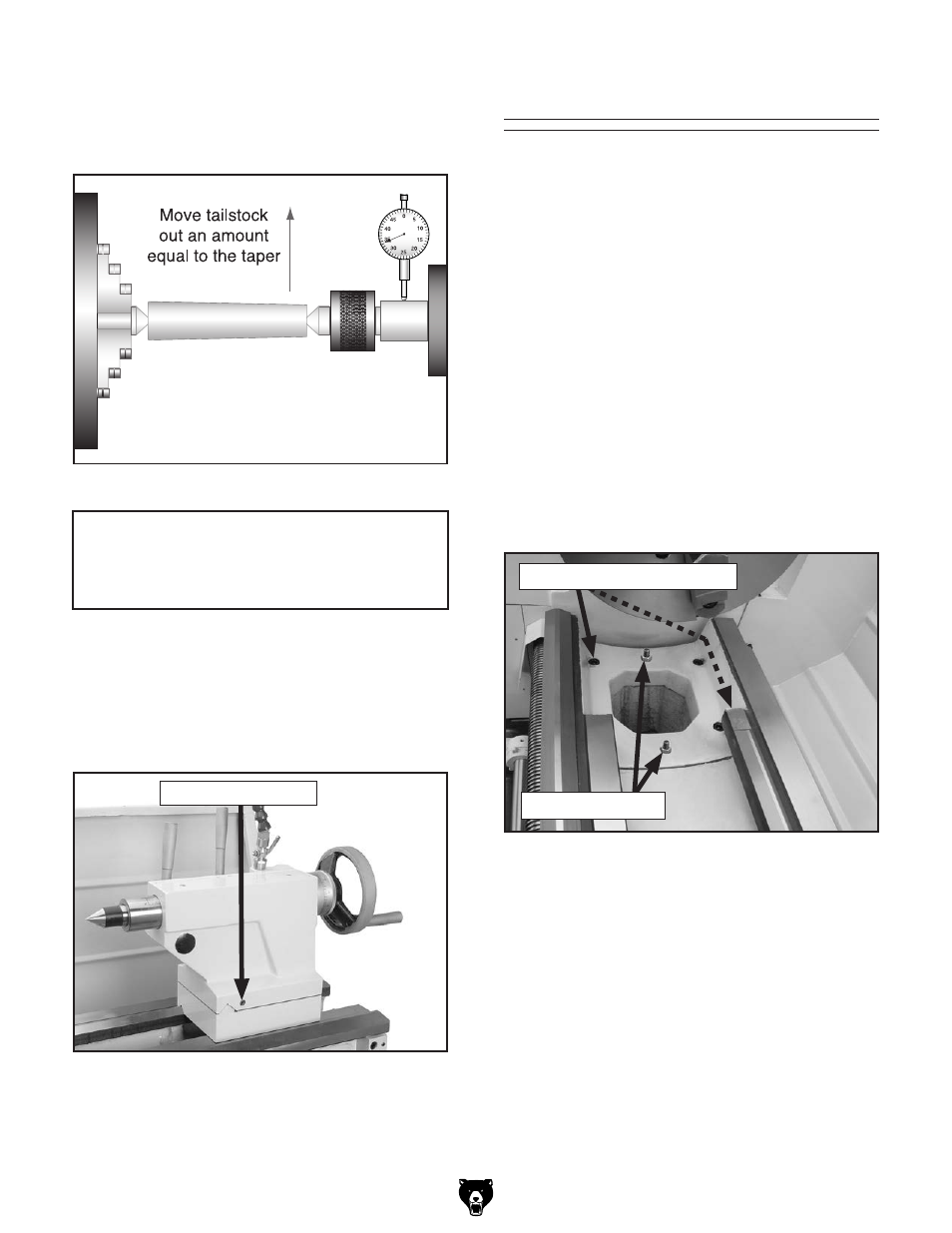

to remove the gap:

1. remove the four cap screws from the bottom

of the gap and two from the ends of the ways

(see

figure 18).

2. using a 14mm wrench, tighten the jack nuts

to draw the pins up and out of the gap piece.

figure 18.

3. tap the outside of the gap with a dead blow

hammer to loosen, and remove the gap sec-

tion.

figure 18. lathe gap and pin arrangement.

Bed and Way Cap screws

Jack nut and pin