Lifting & moving the lathe – Grizzly G0509 User Manual

Page 20

-18-

G0509 & G0509G 16" x 40" Lathe

lifting & moving

the lathe

this lathe can be placed on the included leveling

studs and cast-iron feet. if the lathe must be se-

cured to the floor, refer to a professional machine

installer for options. in either case, the lathe must

be sitting flat at each mounting point, and the ways

must be perfectly level. the bed cannot be twisted

or bent. if a misalignment condition arises, shim

the lathe where it mounts to the floor, or adjust the

feet studs until the bed and ways are in alignment

as shown by precision machinist's levels.

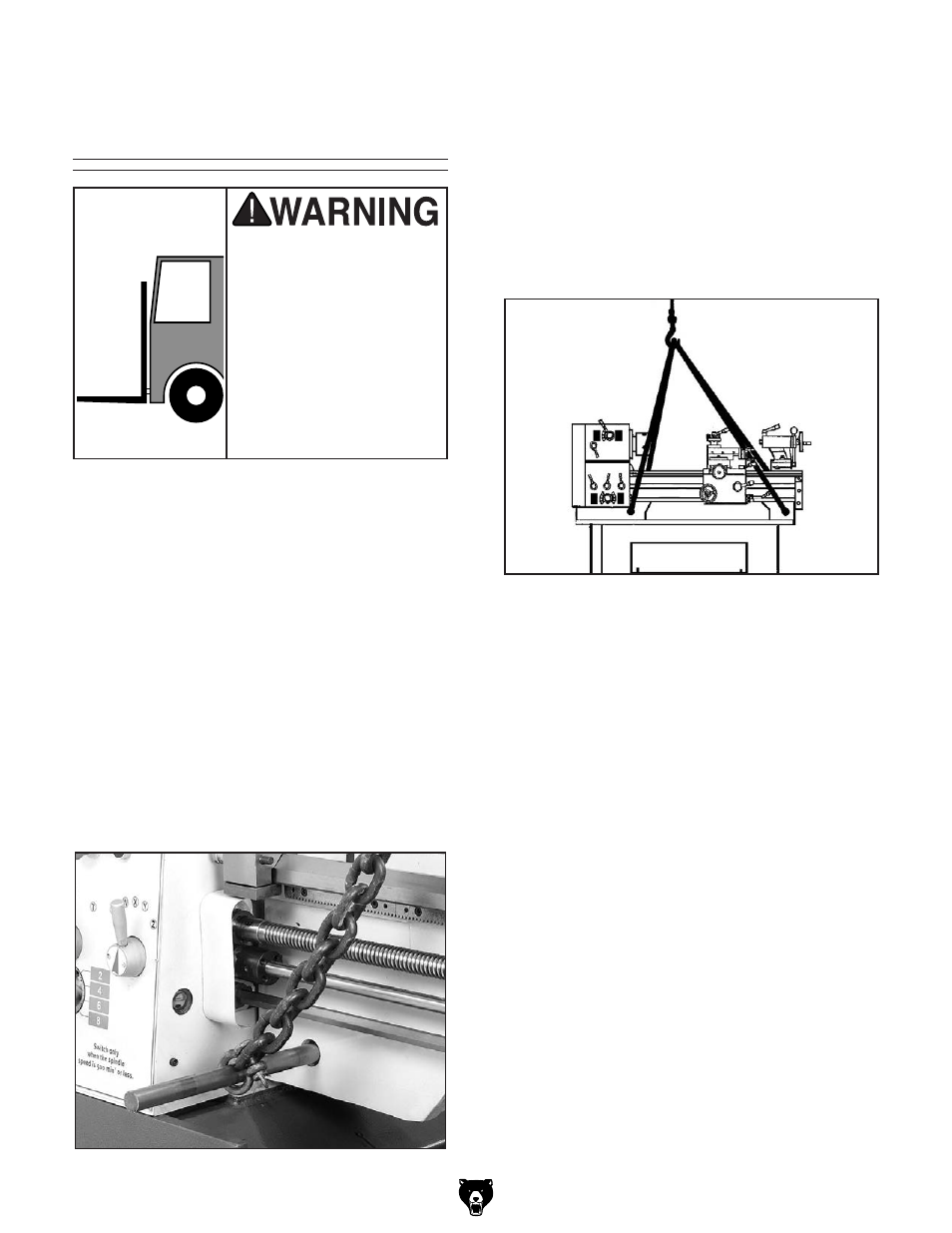

Make sure the slings or chains are routed so when

the lathe is lifted and the chains or straps are tight,

the control rod, lead screw, or feed rod are not

bent.

remember, the headstock carries most of

the weight of this machine (see

figure 5) for safe

chain or strap routing and connection.

this lathe is an extremely

heavy machine. serious

personal injury or death

may occur if safe lifting

and moving methods are

not followed. seek assis-

tance from a professional

rigger if you are unsure

about your abilities or

maximum load ratings of

your lifting equipment.

figure 5. lifting rod setup for the lathe.

figure 6. lifting strap locations.

double check weight ratings and connections of

the lifting system, cables, chains pins, and clevis

links before lifting and moving the lathe to your

prepared location. do not attempt to lift or move

this lathe if you are unsure about any aspect. seek

assistance from a professional rigger if required.

When lifting, you must move the carriage and

tailstock to the right and lock into place as shown

in

figure 6 to provide counter-balance.