Test run & break-in, Notice – Grizzly G0509 User Manual

Page 22

-20-

G0509 & G0509G 16" x 40" Lathe

test run & break-in

the purpose of the test run is to make sure the

lathe and its safety features operate correctly. if

you encounter any problems, stop the lathe and

refer to

troubleshooting on page 43 for correc-

tions.

to begin the test run & break-in procedure:

1. Make sure the lathe is lubricated and the

headstock oil level is full. refer to

lubrication

on

page 41.

2. Make sure the chuck is correctly secured to

the spindle. refer to

mounting chuck and

faceplate on page 35 for details.

3. disengage the feed and half-nut levers, and

move the spindle on/oFF lever to the neutral

position, as shown in

figure 9.

NOTICE

never shift lathe gears when lathe is

operating, and make sure both the half-nut

lever and the feed lever are disengaged

before you start the lathe! otherwise the

lathe will feed the apron into the chuck or

tailstock, causing severe lathe damage.

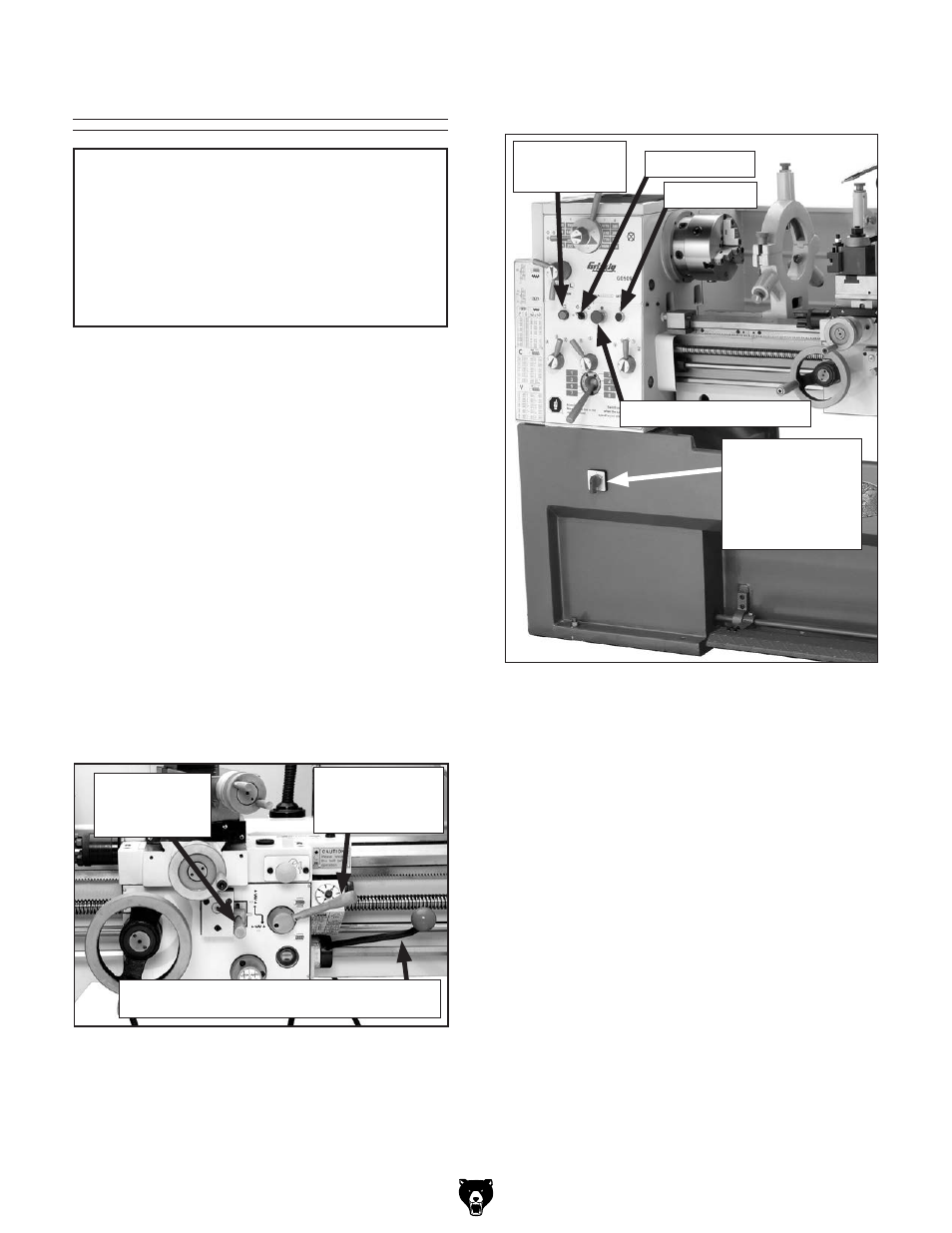

figure 9. Apron controls positioned for test run.

Feed lever is

horizontal

(disengaged)

half-nut lever

is pulled up

(disengaged)

spindle rotation on/oFF lever in

Central position (Motor OFF)

figure 10. Motor high/low range switch.

Motor high/low

range switch:

1 = low

i = off

2 = high

green power

lamp

Jog Button

pump switch

Emergency stop Button

5. on the g0509g lathe, make sure the four

spider bolts are either removed or they are

tight in the spindle so they will not rattle out

and contact the lathe end cover, causing

damage when the lathe is running.

6. Make sure the pump switch is OFF, and turn

the motor high/low range switch (

figure 10)

to "

1" and the green power lamp will glow.

7. put on safety glasses, tie back longhair,

sleeves, and loose clothing.

8. turn the work lamp ON and OFF.

9. point the coolant nozzles into the chip pan,

turn the pump switch

ON, make sure coolant

flows, and then turn the pump switch

OFF.

10. push the jog button (figure 10) a few times

and the spindle motor will turn

ON and the

chuck will rotate.

4. rotate the red emergency stop button (figure

10) clockwise so it pops out.