FUJITSU M304X User Manual

Page 29

multiple-part forms are used, the forms can have different weights of

parts (layers),

the weight of each part should be that given in

Table 2.8 according to the number of parts.

When forms

too thick, density fading between the top and bottom of each

character will occur.

When forms are too thin, they will be damaged and a

feed defect will occur.

(4) Forms causing feed defects

The following forms are likely to cause feed defects, excluding those

described before:

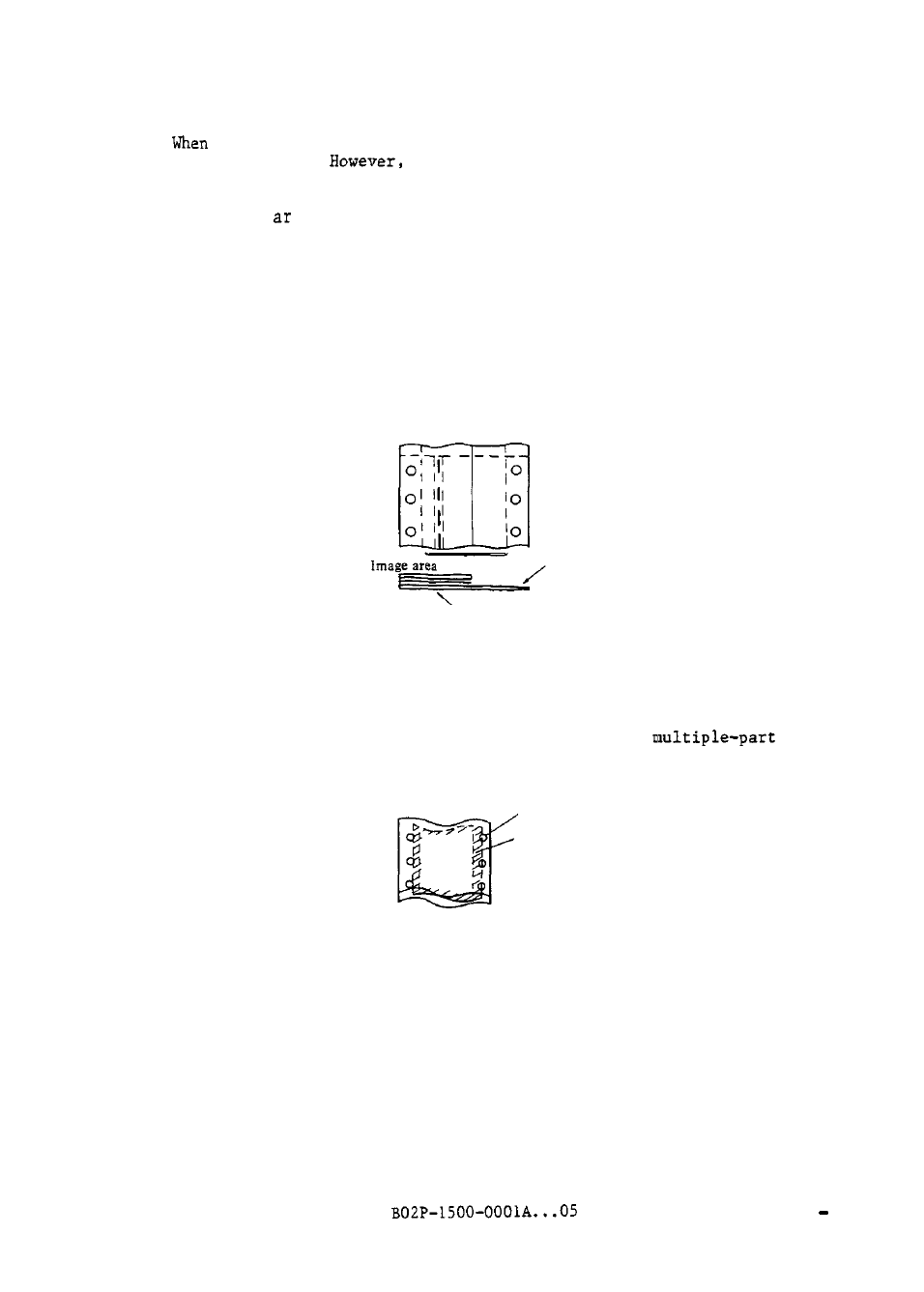

. Multiple-part forms with layers whose thickness or number varies by

section, such as shown in Figure 2.16.

Glued portions

'Glued portions

Figure 2.16 Multi-part forms with layers of different thickness

. Multiple-part forms with layers glued in the print: area (Printing should

not be done on the glued portions.)

. Carbon paper which is covering pin feed holes of

forms

(see Figure 2.17.)

Pin feed hole

Carbon paper

Figure 2.17

Carbon paper covering pin feed holes

. Self-adhesive label form with labels whose all sides are cut (see

Figure 2.18)

Such forms are likely to peel off.

The forms feed 'direction side of every

label must be perforations to prevent peeling.

2 17