3 lubrication, And adhesive – Epson 4003353 User Manual

Page 116

Maintenance

6.3 LUBRICATION

AND ADHESIVE

The printer must be lubricated properly when the printer is disassembled for component

replacement, or if the mechanical noise exceeds a certain level. EPSON recommends only the

lubricants listed in table below for this printer, both of which have been tested extensively and

found to comply with the requirements of this printer mechanism. Figure 6-2 shows the lubrication

points.

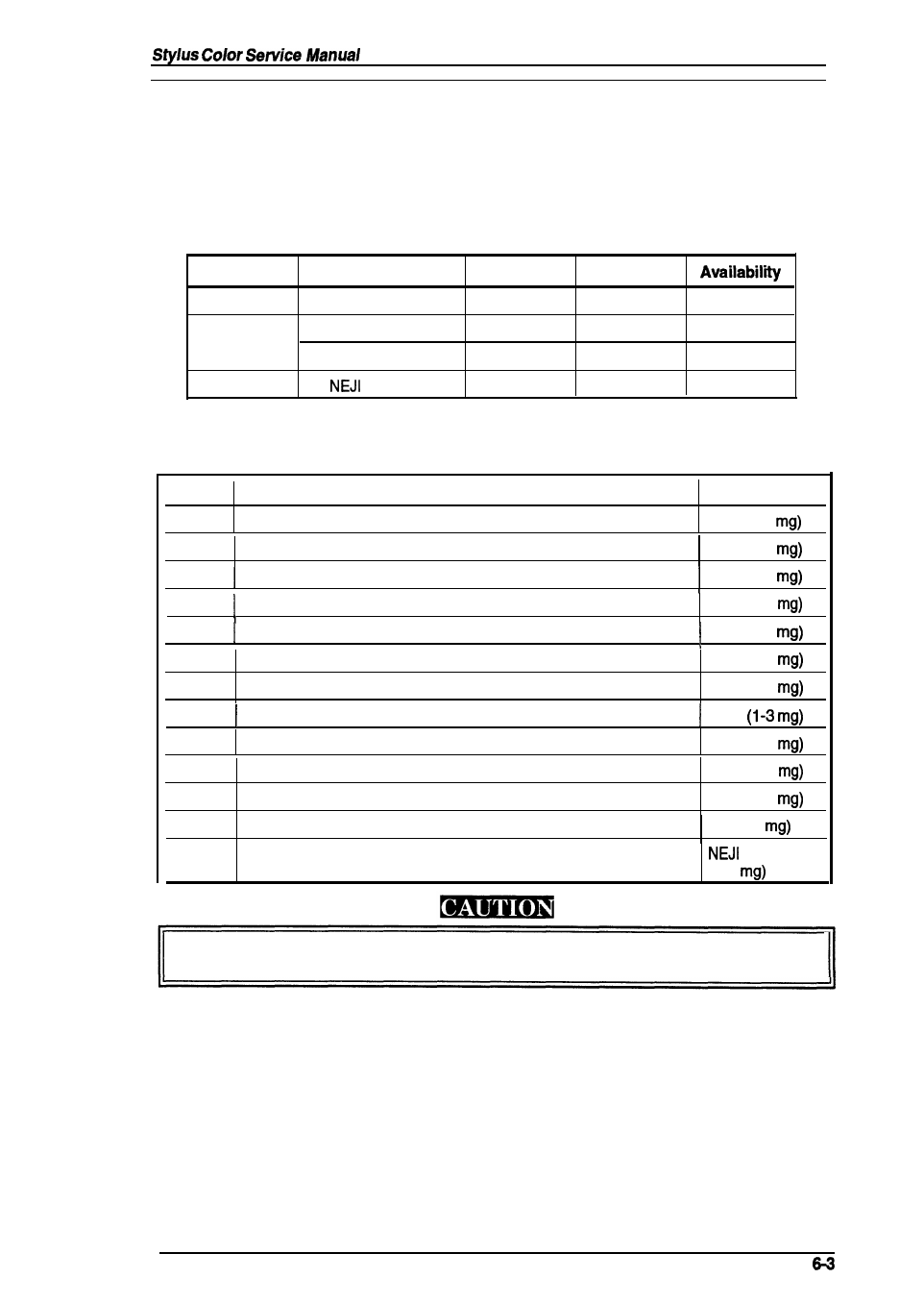

Table 6-1. Recommended Lubricants

Type

Name

Q’ty

Part No.

Oil

o-5

40

cc

1010513

E

G-20

40 gm

B700000001

E

Grease

G-36

40 gm

B703600001

E

Adhesive

LOCK #2 (G)

1000 g

B730200200

E

Note)

E= EPSON Exclusive product (Not commercially available)

Table 6-2. Lubrication and Adhesive Points

Ref. No.

Lubrication/Adhesive Point

Lubricant

(1)

Extreme point of the knob (Gear)

G-36 (l-3

(2)

Cut

point

for knob on the right main frame

G-36 (l-3

(3)

Extreme point of shaft securing sub frame assembly

G-36 (l-3

I

(4)

Gearing point of the complex gear

G-36 (l-3

(5)

Both sides of gear holder (2-points)

G-36 (l-3

I

(6)

Shaft located at the center frame assembly (2-points)

G-36 (l-3

(7)

Cut point for the CR motor on the base frame assembly (2-points)

G-36 (l-3

(8)

Right

extreme point of the eject roller assembly

G-36

(9)

Contact point of the pressure spring and washer

G-36 (l-3

(lo)

Right side of the front paper guide

G-20 (l-3

(11)

Cut point on the platen roller shaft

G-20 (l-3

(12)

Oil pad on the carriage

05 (l-3

(13)

On securing the screw

LOCK #2

(l-3

■

Do not apply too much lubricant, as it may cause a stain on the mechanism as well as a

malfunction of the mechanism.

Rev. A