2 • operation, Filling the sealer, Adjusting the stacker – Pitney Bowes DI425 FastPac Inserting Systems User Manual

Page 24

2 • Operation

2-8

SV61656 Rev. A

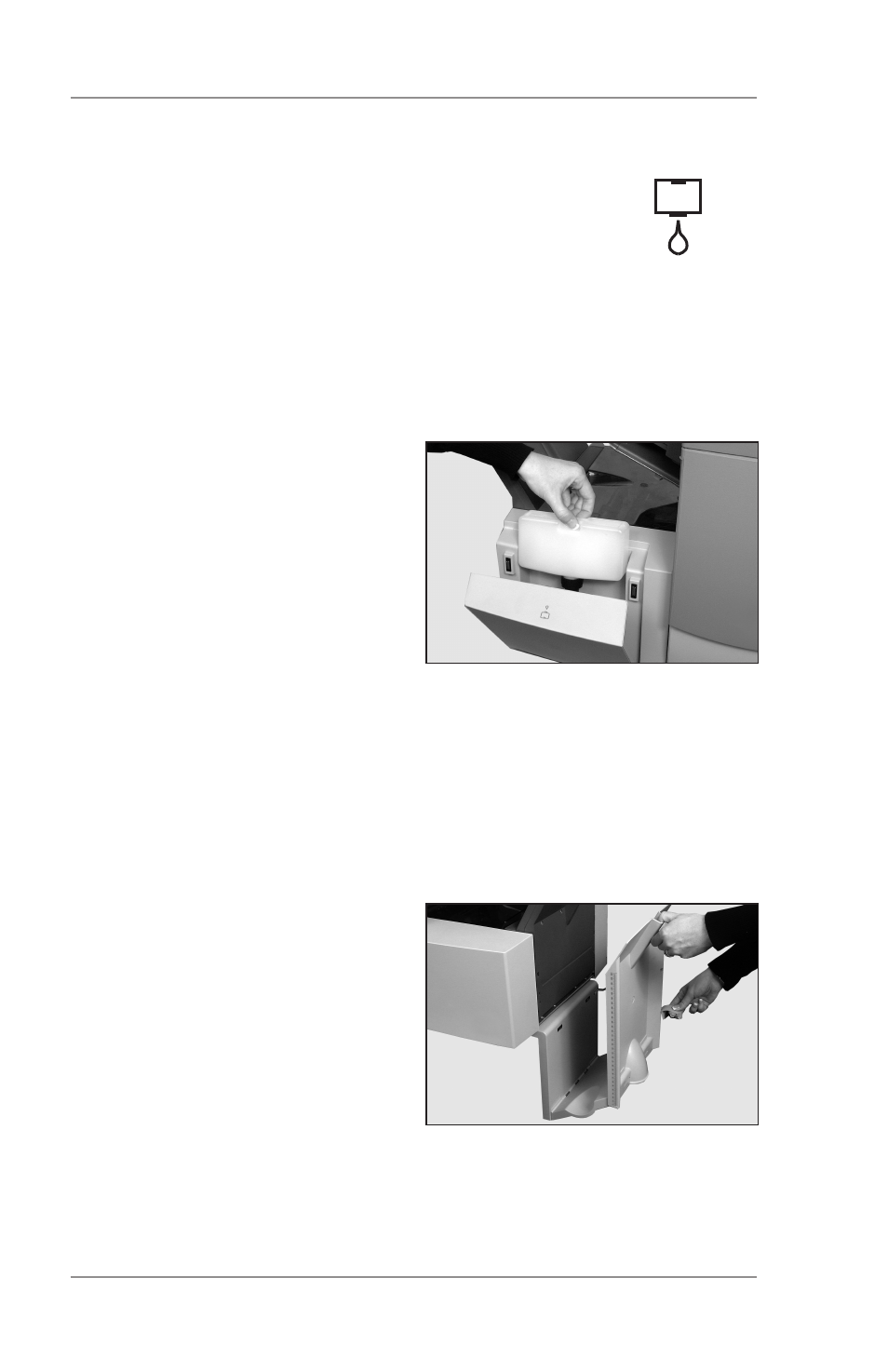

Filling the Sealer

When the sealer unit needs refilling, the

Add Sealing

Solution symbol flashes in the display.

Add E-Z Seal® or water in the following way:

Note: We recommend E-Z Seal® to minimize scale buildup

and the growth of algae.

Hinge open the sealer bottle cov-

er located at the rear right hand

side of the machine. Remove the

bottle.

Fill the bottle up to the level indi-

cated.

Put the sealer bottle back in posi-

tion and close the cover.

Note: If the sealer unit has emptied completely, allow enough time

for the solution to soak through the sealer mechanism. This

helps assure good seals.

Adjusting the Stacker

Adjust the drop stacker to suit the

material you’re running.

Lift the lever at the rear of the

stacker and adjust the stacker

to one of the preset positions.

Lower the lever to lock the stack-

er into position.

When not in use, you can raise

and latch the stacker vertically against the exit area of the machine

as shown in the photo above.